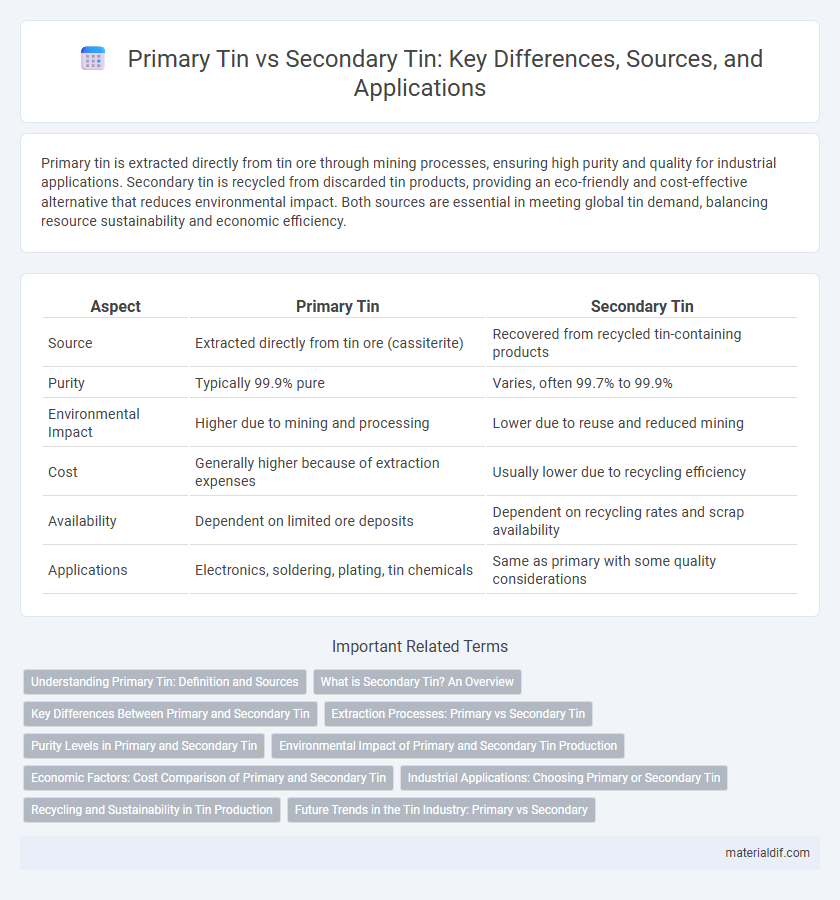

Primary tin is extracted directly from tin ore through mining processes, ensuring high purity and quality for industrial applications. Secondary tin is recycled from discarded tin products, providing an eco-friendly and cost-effective alternative that reduces environmental impact. Both sources are essential in meeting global tin demand, balancing resource sustainability and economic efficiency.

Table of Comparison

| Aspect | Primary Tin | Secondary Tin |

|---|---|---|

| Source | Extracted directly from tin ore (cassiterite) | Recovered from recycled tin-containing products |

| Purity | Typically 99.9% pure | Varies, often 99.7% to 99.9% |

| Environmental Impact | Higher due to mining and processing | Lower due to reuse and reduced mining |

| Cost | Generally higher because of extraction expenses | Usually lower due to recycling efficiency |

| Availability | Dependent on limited ore deposits | Dependent on recycling rates and scrap availability |

| Applications | Electronics, soldering, plating, tin chemicals | Same as primary with some quality considerations |

Understanding Primary Tin: Definition and Sources

Primary tin refers to tin metal extracted directly from tin-bearing ores such as cassiterite, which contains tin dioxide (SnO2). Major sources of primary tin include mining operations in countries like China, Indonesia, and Peru, where raw ore undergoes beneficiation to separate tin minerals from impurities. This process ensures high-purity tin production essential for electronics, soldering, and tin plating applications.

What is Secondary Tin? An Overview

Secondary tin refers to tin recovered from scrap materials, such as electronic waste, tin plating residues, and discarded products containing tin. This recycled tin significantly reduces the need for mining primary tin ore, helping conserve natural resources and lower environmental impact. Advances in refining technologies ensure secondary tin meets industry-quality standards, making it a sustainable alternative to primary tin.

Key Differences Between Primary and Secondary Tin

Primary tin is extracted directly from tin ore through mining processes, ensuring high purity and consistency, while secondary tin is recovered from recycled tin-containing materials such as electronic waste and scrap, contributing to environmental sustainability. The production of primary tin involves complex refining and smelting stages, whereas secondary tin refining focuses on purification and reprocessing techniques to remove contaminants. Key differences include resource origin, processing methods, cost efficiency, and environmental impact, with secondary tin playing a crucial role in reducing reliance on natural reserves and minimizing ecological footprint.

Extraction Processes: Primary vs Secondary Tin

Primary tin extraction involves mining cassiterite ore, followed by concentration through gravity separation and smelting to produce refined tin metal. Secondary tin extraction relies on recycling scrap tin materials through melting and refining, significantly reducing the need for raw ore and lowering environmental impact. Industrial processes prioritize energy efficiency and purity in both methods to meet demand for high-quality tin in electronics and soldering applications.

Purity Levels in Primary and Secondary Tin

Primary tin, extracted directly from tin ores such as cassiterite, typically exhibits high purity levels often exceeding 99.9%, making it ideal for electronic and soldering applications. Secondary tin, derived from recycled materials including tin-bearing scrap and discarded products, usually has slightly lower purity, often ranging between 95% and 99%, depending on the recycling process and source contamination. Advanced refining techniques are employed to enhance the purity of secondary tin to meet industrial standards close to those of primary tin.

Environmental Impact of Primary and Secondary Tin Production

Primary tin production, derived from mining cassiterite ore, often results in significant environmental degradation, including habitat destruction, soil erosion, and water pollution from tailings and smelting processes. Secondary tin production, obtained through recycling scrap tin materials, drastically reduces energy consumption, greenhouse gas emissions, and minimizes the need for raw material extraction, promoting sustainable resource management. Emphasizing secondary tin contributes to lower environmental footprints and conservation of natural ecosystems compared to the more resource-intensive primary production methods.

Economic Factors: Cost Comparison of Primary and Secondary Tin

Primary tin production involves the extraction of tin ore from mines, resulting in higher operational costs due to energy-intensive mining and refining processes. Secondary tin, sourced from the recycling of tin-containing materials, offers a cost advantage by reducing raw material expenses and minimizing environmental compliance costs. Economic factors favor secondary tin when market prices are volatile, as recycling provides a more stable and often lower-cost supply chain.

Industrial Applications: Choosing Primary or Secondary Tin

Primary tin, extracted from cassiterite ore, offers superior purity essential for high-performance electronics and specialized soldering applications, while secondary tin, recycled from scrap materials, provides a cost-effective and environmentally sustainable alternative for mass production and less critical uses. Industrial sectors such as automotive and packaging favor secondary tin due to lower costs and reduced environmental impact, whereas aerospace and medical device manufacturing demand the consistent quality of primary tin. Selecting between primary and secondary tin depends on balancing performance requirements with economic and ecological considerations within specific industrial processes.

Recycling and Sustainability in Tin Production

Primary tin production involves extracting tin ore from mining activities, providing high-purity tin essential for electronics and soldering applications. Secondary tin is sourced from recycled materials, significantly reducing environmental impact by conserving natural resources and lowering energy consumption compared to primary extraction. Emphasizing recycled tin supports sustainability goals in tin supply chains by minimizing waste and enhancing resource efficiency.

Future Trends in the Tin Industry: Primary vs Secondary

The future of the tin industry increasingly favors secondary tin due to rising sustainability demands and stricter environmental regulations, driving growth in tin recycling technologies. Innovations in efficient extraction and purification processes for recycled tin are expected to reduce dependency on primary tin mining, which faces challenges like resource depletion and geopolitical instability. Market forecasts predict a significant shift with secondary tin supply potentially accounting for over 40% of global consumption by 2030, reshaping supply chains and investment strategies in the tin sector.

Primary Tin vs Secondary Tin Infographic

materialdif.com

materialdif.com