Tin coating provides a pure, uniform layer that offers excellent corrosion resistance and good solderability, making it ideal for protecting base metals in packaging and electronics. In contrast, tin alloy coatings combine tin with other metals such as copper or lead, enhancing mechanical strength and wear resistance while maintaining protective qualities. Choosing between tin coating and tin alloy depends on specific application requirements, balancing between pure tin's conductivity and the alloy's durability.

Table of Comparison

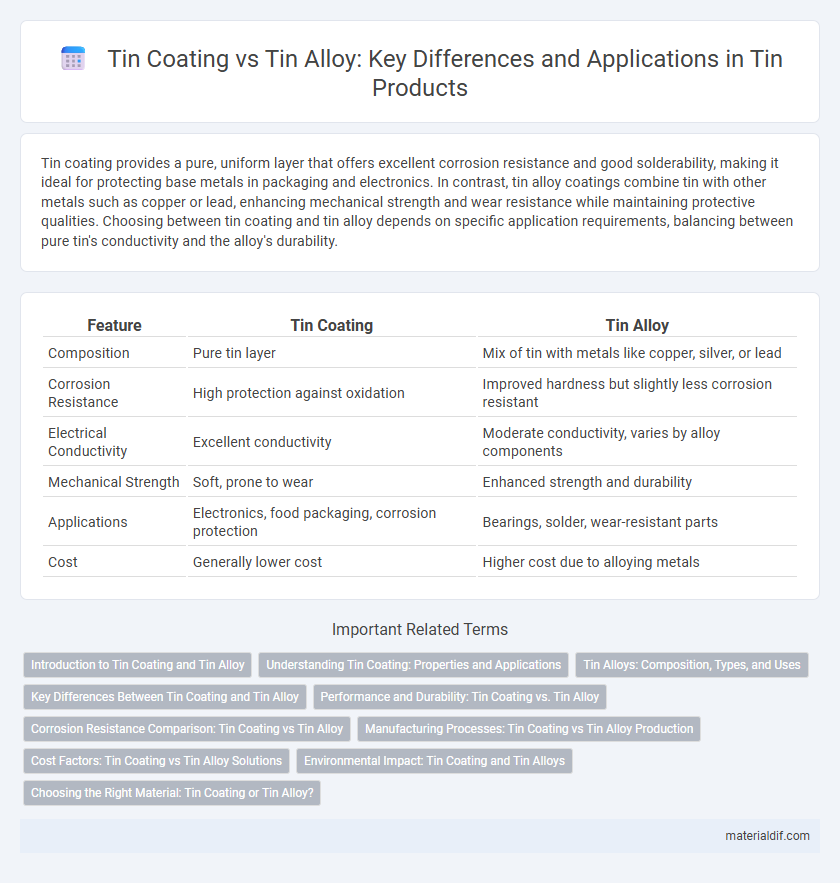

| Feature | Tin Coating | Tin Alloy |

|---|---|---|

| Composition | Pure tin layer | Mix of tin with metals like copper, silver, or lead |

| Corrosion Resistance | High protection against oxidation | Improved hardness but slightly less corrosion resistant |

| Electrical Conductivity | Excellent conductivity | Moderate conductivity, varies by alloy components |

| Mechanical Strength | Soft, prone to wear | Enhanced strength and durability |

| Applications | Electronics, food packaging, corrosion protection | Bearings, solder, wear-resistant parts |

| Cost | Generally lower cost | Higher cost due to alloying metals |

Introduction to Tin Coating and Tin Alloy

Tin coating provides a thin, protective layer of pure tin applied to metal surfaces to enhance corrosion resistance and improve solderability. Tin alloys combine tin with other metals like copper or lead, offering enhanced mechanical strength and wear resistance compared to pure tin coatings. Understanding the properties and applications of tin coatings versus tin alloys is essential for selecting the appropriate material in electronics, packaging, and automotive industries.

Understanding Tin Coating: Properties and Applications

Tin coating offers excellent corrosion resistance and solderability, making it ideal for protecting steel substrates in electronics and food packaging. It forms a thin, uniform layer that prevents oxidation while maintaining electrical conductivity, crucial for circuit boards and connectors. In contrast, tin alloys combine tin with other metals to enhance mechanical strength and wear resistance, but tin coatings specifically excel in lightweight, cost-effective surface protection.

Tin Alloys: Composition, Types, and Uses

Tin alloys typically combine tin with metals such as copper, antimony, and zinc to enhance mechanical strength, corrosion resistance, and electrical conductivity. Common types include bronze (tin-copper alloy), pewter (tin-lead-antimony alloy), and babbitt metal (tin-lead-based alloy), each tailored for specific applications like bearings, soldering, and decorative items. The versatility of tin alloys stems from their ability to balance malleability and durability, making them essential in automotive, aerospace, and electronics industries.

Key Differences Between Tin Coating and Tin Alloy

Tin coating provides a thin, pure layer of tin applied to a substrate to enhance corrosion resistance and solderability, while tin alloy consists of a mixture of tin with other metals such as copper, silver, or nickel, offering improved mechanical properties and wear resistance. Tin coatings are commonly used in electronics and food packaging for protection and conductivity, whereas tin alloys find applications in bearings, solders, and mechanical components requiring higher strength and durability. The primary difference lies in composition and function: tin coating modifies surface characteristics without altering bulk material properties, whereas tin alloys change the intrinsic material characteristics through alloying.

Performance and Durability: Tin Coating vs. Tin Alloy

Tin coating provides excellent corrosion resistance and electrical conductivity, making it ideal for protecting base metals in electronics and packaging industries. Tin alloys, such as tin-lead or tin-silver, offer enhanced mechanical strength and improved wear resistance, which increase durability under high-stress conditions. Performance differences between pure tin coatings and tin alloys depend on application requirements, with alloys generally outperforming coatings in extreme mechanical and thermal environments.

Corrosion Resistance Comparison: Tin Coating vs Tin Alloy

Tin coating provides a sacrificial barrier that effectively protects underlying metals from corrosion by preventing direct exposure to moisture and oxygen. Tin alloys, composed of tin combined with other metals like copper or silver, offer enhanced mechanical strength but may exhibit varied corrosion resistance depending on the alloy composition and environmental conditions. In general, pure tin coatings excel in corrosion resistance for applications requiring surface protection, while tin alloys balance corrosion resistance with improved durability and wear resistance.

Manufacturing Processes: Tin Coating vs Tin Alloy Production

Tin coating involves electrolytic or hot-dip plating processes where pure tin is deposited onto a substrate, providing corrosion resistance and enhanced solderability. Tin alloy production requires melting tin with other metals such as copper, lead, or silver, followed by casting or rolling to form homogeneous solid solutions with specific mechanical and electronic properties. Manufacturing tin coatings is typically faster and used for surface protection, while tin alloy production demands precise temperature control and metallurgical expertise to achieve desired material characteristics.

Cost Factors: Tin Coating vs Tin Alloy Solutions

Tin coating typically involves a lower initial cost due to simpler application methods such as electroplating or hot-dip coating, making it suitable for budget-conscious projects. Tin alloy solutions, incorporating metals like copper or lead, often incur higher material and processing expenses but offer enhanced mechanical strength and corrosion resistance, justifying the increased investment. Cost factors must weigh the balance between upfront expenses and long-term performance benefits for specific industrial applications.

Environmental Impact: Tin Coating and Tin Alloys

Tin coating significantly reduces environmental pollution by providing a non-toxic, corrosion-resistant layer that extends the lifespan of metals and minimizes waste. Tin alloys, depending on their composition, may contain elements such as lead or antimony, which pose greater environmental risks during production and recycling processes. The use of pure tin coatings offers a more sustainable alternative by enhancing recyclability and lowering toxic metal emissions.

Choosing the Right Material: Tin Coating or Tin Alloy?

Selecting between tin coating and tin alloy depends on the application's corrosion resistance and mechanical strength requirements. Tin coating provides an effective barrier against oxidation and improves solderability on base metals, ideal for electronic components and food packaging. Tin alloys, often combined with metals like copper or silver, offer enhanced durability and wear resistance, making them suitable for bearings, plumbing, and electrical contacts.

Tin coating vs Tin alloy Infographic

materialdif.com

materialdif.com