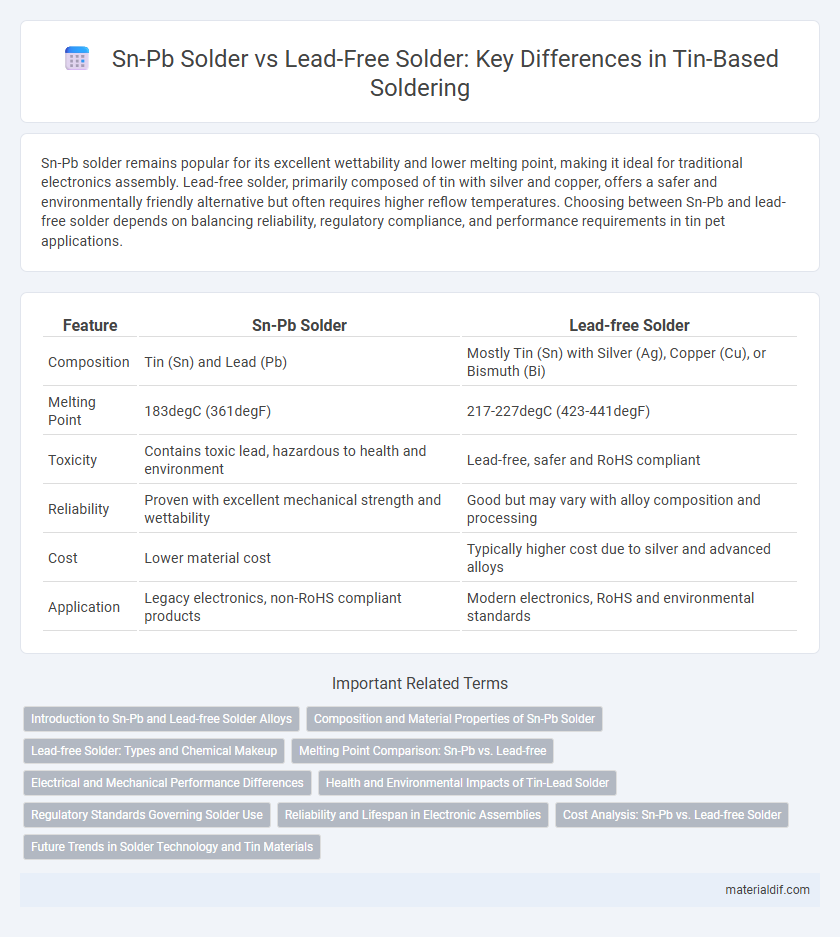

Sn-Pb solder remains popular for its excellent wettability and lower melting point, making it ideal for traditional electronics assembly. Lead-free solder, primarily composed of tin with silver and copper, offers a safer and environmentally friendly alternative but often requires higher reflow temperatures. Choosing between Sn-Pb and lead-free solder depends on balancing reliability, regulatory compliance, and performance requirements in tin pet applications.

Table of Comparison

| Feature | Sn-Pb Solder | Lead-free Solder |

|---|---|---|

| Composition | Tin (Sn) and Lead (Pb) | Mostly Tin (Sn) with Silver (Ag), Copper (Cu), or Bismuth (Bi) |

| Melting Point | 183degC (361degF) | 217-227degC (423-441degF) |

| Toxicity | Contains toxic lead, hazardous to health and environment | Lead-free, safer and RoHS compliant |

| Reliability | Proven with excellent mechanical strength and wettability | Good but may vary with alloy composition and processing |

| Cost | Lower material cost | Typically higher cost due to silver and advanced alloys |

| Application | Legacy electronics, non-RoHS compliant products | Modern electronics, RoHS and environmental standards |

Introduction to Sn-Pb and Lead-free Solder Alloys

Sn-Pb solder alloys, primarily composed of approximately 60% tin (Sn) and 40% lead (Pb), have been the industry standard due to their low melting point and excellent wetting properties, making them ideal for reliable electrical connections. Lead-free solder alloys, such as SAC (tin-silver-copper) variants, have emerged as environmentally friendly alternatives, driven by regulations like RoHS that restrict lead usage in electronics. These lead-free solders typically offer higher melting points and improved mechanical strength but require modified processing techniques to ensure comparable performance in electronic assembly.

Composition and Material Properties of Sn-Pb Solder

Sn-Pb solder typically consists of 60% tin (Sn) and 40% lead (Pb), offering a low melting point around 183degC, which facilitates easier soldering processes. The presence of lead enhances the alloy's ductility and wetting properties, resulting in reliable mechanical strength and excellent electrical conductivity. Despite its toxicity, Sn-Pb solder maintains superior thermal fatigue resistance compared to many lead-free alternatives.

Lead-free Solder: Types and Chemical Makeup

Lead-free solder primarily consists of a blend of tin (Sn) with metals such as silver (Ag), copper (Cu), and sometimes bismuth (Bi) or indium (In), enhancing its melting point and mechanical properties. Common formulations include Sn-Ag-Cu alloys (SAC), typically Sn-3.0Ag-0.5Cu, which offer improved environmental safety by eliminating lead (Pb) content while maintaining reliable electrical conductivity. The chemical makeup of lead-free solders targets reductions in toxicity and compliance with regulations like RoHS, making them preferable in electronic assembly for both consumer and industrial applications.

Melting Point Comparison: Sn-Pb vs. Lead-free

Sn-Pb solder typically melts around 183degC, offering a lower and more consistent melting point compared to most lead-free solders, which generally melt between 217degC and 227degC. Lead-free solders, often based on tin-silver-copper (SAC) alloys, require higher temperatures that can impact component reliability and increase thermal stress. The difference in melting points is crucial for manufacturing processes where temperature sensitivity and energy consumption are key factors.

Electrical and Mechanical Performance Differences

Sn-Pb solder exhibits superior electrical conductivity and lower melting point compared to lead-free alternatives, contributing to enhanced electrical performance and ease of reflow in electronics assembly. Lead-free solders, commonly based on tin-silver-copper (SAC) alloys, offer improved mechanical strength and better thermal fatigue resistance, which are critical for long-term reliability in high-temperature environments. The trade-off involves slightly higher electrical resistivity and increased melting temperatures in lead-free solders, impacting both power efficiency and manufacturing processes.

Health and Environmental Impacts of Tin-Lead Solder

Tin-lead solder, composed primarily of tin (Sn) and lead (Pb), poses significant health risks due to lead's toxicity, which can cause neurological damage and developmental issues. Environmentally, lead contamination from improper disposal or manufacturing processes leads to soil and water pollution, adversely affecting ecosystems and human health. In contrast, lead-free solder reduces these hazards by eliminating lead, offering a safer alternative for both workers and the environment without compromising soldering performance.

Regulatory Standards Governing Solder Use

Regulatory standards such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) significantly influence the use of Sn-Pb solder versus lead-free solder in electronics manufacturing. Sn-Pb solder, containing approximately 63% tin and 37% lead, is restricted in many regions due to lead's toxicity and environmental impact, prompting industry shifts toward lead-free alternatives like SAC305 (tin-silver-copper). Compliance with these standards ensures reduced hazardous waste and adherence to global directives, positioning lead-free solder as the preferred material in meeting modern environmental and health regulations.

Reliability and Lifespan in Electronic Assemblies

Sn-Pb solder offers superior reliability in electronic assemblies due to its low melting point and excellent wetting properties, resulting in fewer defects and longer lifespan. Lead-free solder, primarily composed of tin with silver and copper, provides environmental benefits but can suffer from increased brittleness and susceptibility to tin whisker growth, potentially reducing assembly durability. Ongoing advancements in lead-free alloy formulations aim to close the reliability gap while meeting international RoHS standards.

Cost Analysis: Sn-Pb vs. Lead-free Solder

Sn-Pb solder typically offers lower material costs and easier processing due to its lower melting point and well-established manufacturing methods. Lead-free solder alloys, such as SAC305, often incur higher costs driven by more expensive raw materials like silver and increased energy consumption during higher-temperature reflow processes. The cost differential also reflects in long-term considerations, with Sn-Pb requiring less frequent rework and lower scrap rates, whereas lead-free solder demands investment in updated equipment and stricter quality control to mitigate reliability issues.

Future Trends in Solder Technology and Tin Materials

Future trends in solder technology emphasize the development of Sn-Pb alternatives due to environmental regulations and health concerns. Lead-free solder alloys, primarily based on tin with additions of silver, copper, and bismuth, are advancing to improve reliability and reduce brittleness in electronic assemblies. Research in tin-based materials focuses on enhancing thermal fatigue resistance and melting point optimization to meet the demands of miniaturized and high-performance devices.

Sn-Pb Solder vs Lead-free Solder Infographic

materialdif.com

materialdif.com