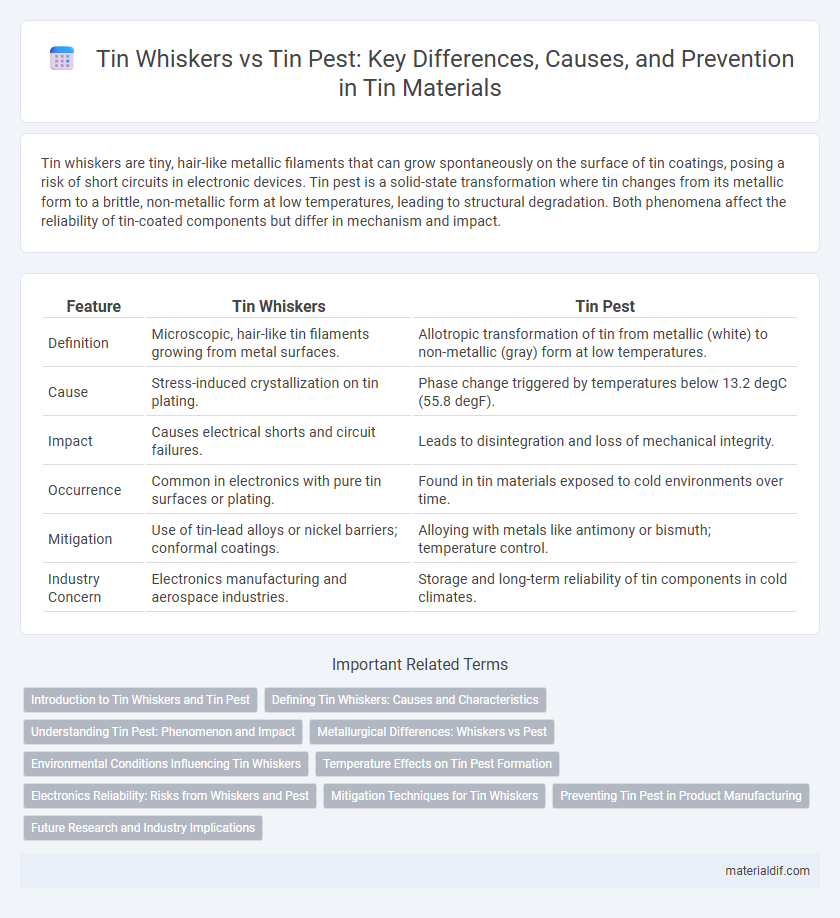

Tin whiskers are tiny, hair-like metallic filaments that can grow spontaneously on the surface of tin coatings, posing a risk of short circuits in electronic devices. Tin pest is a solid-state transformation where tin changes from its metallic form to a brittle, non-metallic form at low temperatures, leading to structural degradation. Both phenomena affect the reliability of tin-coated components but differ in mechanism and impact.

Table of Comparison

| Feature | Tin Whiskers | Tin Pest |

|---|---|---|

| Definition | Microscopic, hair-like tin filaments growing from metal surfaces. | Allotropic transformation of tin from metallic (white) to non-metallic (gray) form at low temperatures. |

| Cause | Stress-induced crystallization on tin plating. | Phase change triggered by temperatures below 13.2 degC (55.8 degF). |

| Impact | Causes electrical shorts and circuit failures. | Leads to disintegration and loss of mechanical integrity. |

| Occurrence | Common in electronics with pure tin surfaces or plating. | Found in tin materials exposed to cold environments over time. |

| Mitigation | Use of tin-lead alloys or nickel barriers; conformal coatings. | Alloying with metals like antimony or bismuth; temperature control. |

| Industry Concern | Electronics manufacturing and aerospace industries. | Storage and long-term reliability of tin components in cold climates. |

Introduction to Tin Whiskers and Tin Pest

Tin whiskers are microscopic, hair-like metallic filaments that grow spontaneously from tin surfaces, often causing short circuits in electronic devices. Tin pest is the allotropic transformation of white tin to gray tin at low temperatures, leading to material disintegration and loss of mechanical strength. Both phenomena pose significant reliability challenges in electronics, necessitating careful material selection and preventive measures.

Defining Tin Whiskers: Causes and Characteristics

Tin whiskers are microscopic, hair-like metallic filaments that spontaneously grow from the surface of tin coatings, often causing electrical short circuits in electronic components. They typically form due to mechanical stress, intermetallic compound formation, or environmental factors like temperature fluctuations and humidity. These whiskers can reach lengths of several millimeters, posing significant reliability challenges in high-reliability sectors such as aerospace and medical devices.

Understanding Tin Pest: Phenomenon and Impact

Tin pest is a low-temperature transformation of white metallic tin (beta-tin) into a brittle, gray powdery form called gray tin (alpha-tin) occurring below 13.2degC, causing structural degradation in tin components. This allotropic transformation results in expansion and cracking, compromising the mechanical integrity of tin coatings, solder joints, and electronic parts, especially in cold environments. Understanding tin pest is crucial for reliable performance in aerospace, cryogenics, and electronics industries where low temperatures accelerate the phenomenon's detrimental effects.

Metallurgical Differences: Whiskers vs Pest

Tin whiskers are fine, hair-like crystalline filaments that grow on the surface of electroplated tin, mainly due to compressive stresses and the metal's microstructure, often causing electrical short circuits. Tin pest, by contrast, is a low-temperature transformation where metallic white tin converts into brittle gray tin below 13degC, leading to material disintegration through a phase change rather than surface growth. Metallurgically, whiskers result from stress-driven grain deformation and atomic diffusion along grain boundaries, while tin pest involves a polymorphic phase transition from the metallic tetragonal b-tin to the nonmetallic diamond-cubic a-tin.

Environmental Conditions Influencing Tin Whiskers

Tin whiskers are microscopic, hair-like metallic filaments that grow spontaneously on pure tin surfaces, primarily under conditions of mechanical stress and compressive forces. Environmental factors such as temperature fluctuations, humidity, and radiation exposure significantly influence whisker growth, with higher stress levels and moisture accelerating their formation. Unlike tin pest, which occurs under extremely low temperatures and causes brittleness, tin whisker development is more strongly linked to the presence of residual stress and environmental humidity.

Temperature Effects on Tin Pest Formation

Tin pest, a degradation phenomenon where crystalline tin transforms to a brittle gray allotrope, accelerates significantly at temperatures below 13degC. Unlike tin whiskers, which grow independently of low temperature, tin pest formation is highly sensitive to cold environments, causing structural failure in electronic components during prolonged exposure to subzero temperatures. Maintaining operating temperatures above the critical threshold is essential to prevent tin pest-induced damage in tin-plated materials.

Electronics Reliability: Risks from Whiskers and Pest

Tin whiskers are microscopic, hair-like metallic filaments that grow from tin surfaces, posing significant reliability risks by causing short circuits and electrical failures in electronic components. Tin pest, a low-temperature transformation of tin from its metallic form to a brittle, powdery allotrope, leads to mechanical degradation and compromised structural integrity in solder joints, especially under cold operating conditions. Both phenomena compromise electronics reliability by inducing failure modes that affect circuitry performance and lifespan, necessitating mitigation strategies in tin-plated components used in critical electronic systems.

Mitigation Techniques for Tin Whiskers

Tin whiskers, microscopic crystalline filaments growing from tin surfaces, pose significant risks in electronic components by causing short circuits and failures. Effective mitigation techniques include applying conformal coatings such as epoxy or polyurethane to physically restrain whisker growth, using tin-lead alloys which significantly reduce whisker formation, and implementing annealing processes to relieve internal stresses in tin plating. Alternative strategies involve incorporating nickel or copper underlayers beneath the tin surface and adopting strict environmental controls to minimize conditions conducive to whisker development.

Preventing Tin Pest in Product Manufacturing

Preventing tin pest in product manufacturing involves maintaining stable storage temperatures above -30degC, as temperatures below this threshold accelerate the transformation of white metallic tin to brittle gray tin. Alloying tin with small percentages of elements such as antimony, bismuth, or copper effectively suppresses tin pest formation by altering tin's crystal structure and enhancing material stability. Implementing protective coatings and controlled environmental conditions further minimize the risk of tin degradation, ensuring long-term reliability in electronic components.

Future Research and Industry Implications

Future research on tin whiskers aims to develop more robust mitigation techniques to prevent short circuits in high-reliability electronics, particularly in aerospace and medical devices where failure can be catastrophic. Understanding tin pest, a low-temperature phase transformation that degrades tin's mechanical integrity, remains crucial for applications in cold environments such as space exploration and cryogenics. Industry implications highlight the need for advanced alloy formulations and protective coatings to enhance tin's durability and reliability while addressing both whisker growth and pest formation.

Tin Whiskers vs Tin Pest Infographic

materialdif.com

materialdif.com