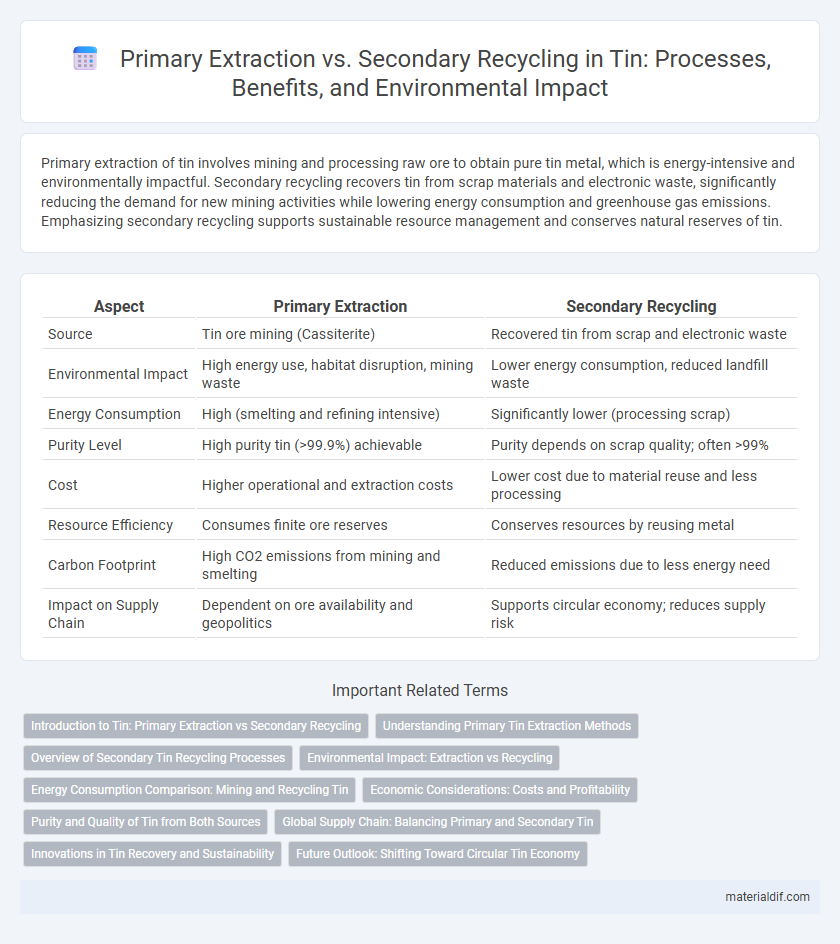

Primary extraction of tin involves mining and processing raw ore to obtain pure tin metal, which is energy-intensive and environmentally impactful. Secondary recycling recovers tin from scrap materials and electronic waste, significantly reducing the demand for new mining activities while lowering energy consumption and greenhouse gas emissions. Emphasizing secondary recycling supports sustainable resource management and conserves natural reserves of tin.

Table of Comparison

| Aspect | Primary Extraction | Secondary Recycling |

|---|---|---|

| Source | Tin ore mining (Cassiterite) | Recovered tin from scrap and electronic waste |

| Environmental Impact | High energy use, habitat disruption, mining waste | Lower energy consumption, reduced landfill waste |

| Energy Consumption | High (smelting and refining intensive) | Significantly lower (processing scrap) |

| Purity Level | High purity tin (>99.9%) achievable | Purity depends on scrap quality; often >99% |

| Cost | Higher operational and extraction costs | Lower cost due to material reuse and less processing |

| Resource Efficiency | Consumes finite ore reserves | Conserves resources by reusing metal |

| Carbon Footprint | High CO2 emissions from mining and smelting | Reduced emissions due to less energy need |

| Impact on Supply Chain | Dependent on ore availability and geopolitics | Supports circular economy; reduces supply risk |

Introduction to Tin: Primary Extraction vs Secondary Recycling

Tin is primarily extracted from cassiterite ore through smelting processes that involve roasting and reduction, yielding high-purity metal essential for electronic soldering and tin plating. Secondary recycling recovers tin from scrap materials such as used electronics, tin cans, and industrial waste, significantly reducing environmental impact and conserving natural ore reserves. The balance between primary extraction and secondary recycling supports sustainable tin supply chains by optimizing resource efficiency and minimizing extraction costs.

Understanding Primary Tin Extraction Methods

Primary tin extraction involves mining cassiterite ore, which typically contains 60-70% tin dioxide (SnO2). The main extraction method includes crushing, grinding, gravity concentration, and smelting to obtain pure tin metal. Hydrometallurgical and pyrometallurgical processes are used to separate tin from impurities, ensuring high-quality primary tin production for industrial use.

Overview of Secondary Tin Recycling Processes

Secondary tin recycling involves recovering tin from scrap materials such as electronic waste, tin-plated steel, and solder residues through processes like mechanical separation, chemical treatment, and refining. Techniques including smelting and electrolysis enable the extraction of high-purity tin, reducing the need for primary ore mining and lowering environmental impact. This sustainable approach optimizes resource efficiency and supports the circular economy in the tin industry.

Environmental Impact: Extraction vs Recycling

Primary extraction of tin involves mining and refining ores, which typically results in significant environmental impacts such as habitat destruction, soil erosion, and greenhouse gas emissions. Secondary recycling of tin reduces the need for mining activities, minimizing ecological footprints by conserving natural resources and lowering energy consumption by up to 60%. Recycling tin also decreases toxic waste generation and air pollution, contributing to more sustainable metal lifecycle management.

Energy Consumption Comparison: Mining and Recycling Tin

Mining tin consumes significantly more energy compared to recycling due to the extensive processes involved in ore extraction, smelting, and refining. Secondary recycling of tin uses up to 90% less energy, as it involves remelting scrap tin without the need for complex ore processing. This energy efficiency makes recycling tin a more sustainable option, reducing carbon emissions and conserving natural resources.

Economic Considerations: Costs and Profitability

Primary extraction of tin involves high capital investment and energy costs due to mining and ore processing, impacting overall profitability. Secondary recycling offers cost-effective benefits by reducing raw material expenses and energy consumption, enhancing economic viability. However, fluctuating tin market prices and recycling infrastructure influence the comparative financial outcomes of both methods.

Purity and Quality of Tin from Both Sources

Primary extraction of tin, sourced from cassiterite ore, typically yields high-purity tin with minimal impurities, ensuring superior metallurgical quality for industrial applications. Secondary recycling processes recover tin from scrap materials but often face challenges in maintaining consistent purity due to contamination from mixed alloys and residues. Advanced refining techniques in secondary recycling can improve tin quality, but primary extraction remains the standard for applications demanding the highest purity levels.

Global Supply Chain: Balancing Primary and Secondary Tin

Global tin supply relies on a balance between primary extraction, which involves mining cassiterite ore predominantly in countries like China, Indonesia, and Peru, and secondary recycling from electronic waste and scrap tin materials. Primary extraction accounts for approximately 78% of global tin production, but increasing environmental regulations and demand volatility are driving growth in secondary recycling efforts to supplement supply. Efficient integration of recycled tin into the global supply chain enhances resource sustainability and mitigates supply disruptions caused by geopolitical or environmental factors.

Innovations in Tin Recovery and Sustainability

Innovations in tin recovery prioritize advanced hydrometallurgical techniques and sensor-based sorting systems to enhance primary extraction efficiency while reducing environmental impact. Secondary recycling leverages cutting-edge chemical leaching processes and electrochemical recovery methods to reclaim high-purity tin from electronic waste and scrap materials. These sustainable approaches significantly decrease reliance on mined tin, lower greenhouse gas emissions, and support circular economy goals in the tin industry.

Future Outlook: Shifting Toward Circular Tin Economy

Primary extraction of tin, dominated by mining cassiterite, faces challenges from resource depletion and environmental regulations, prompting a gradual shift toward secondary recycling. Advances in recycling technologies enable efficient recovery of tin from electronic waste and scrap, significantly reducing reliance on virgin ore. The future outlook emphasizes a circular tin economy, fostering sustainability by maximizing tin reuse, minimizing waste, and lowering carbon footprints in industry supply chains.

Primary Extraction vs Secondary Recycling Infographic

materialdif.com

materialdif.com