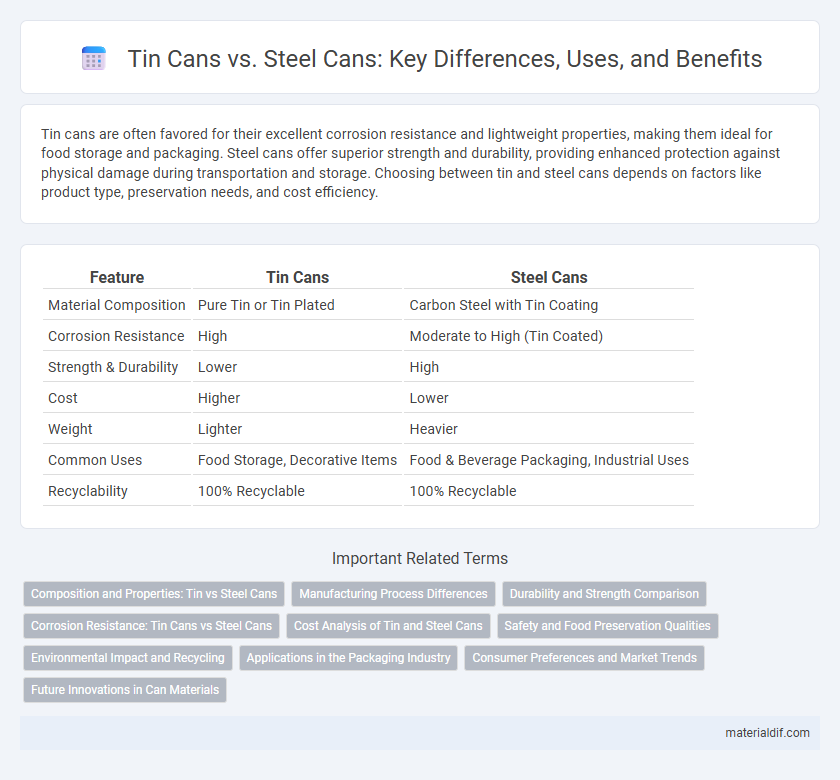

Tin cans are often favored for their excellent corrosion resistance and lightweight properties, making them ideal for food storage and packaging. Steel cans offer superior strength and durability, providing enhanced protection against physical damage during transportation and storage. Choosing between tin and steel cans depends on factors like product type, preservation needs, and cost efficiency.

Table of Comparison

| Feature | Tin Cans | Steel Cans |

|---|---|---|

| Material Composition | Pure Tin or Tin Plated | Carbon Steel with Tin Coating |

| Corrosion Resistance | High | Moderate to High (Tin Coated) |

| Strength & Durability | Lower | High |

| Cost | Higher | Lower |

| Weight | Lighter | Heavier |

| Common Uses | Food Storage, Decorative Items | Food & Beverage Packaging, Industrial Uses |

| Recyclability | 100% Recyclable | 100% Recyclable |

Composition and Properties: Tin vs Steel Cans

Tin cans are primarily composed of steel coated with a thin layer of tin to prevent corrosion, combining the strength and rigidity of steel with the corrosion resistance of tin. Steel cans offer superior structural integrity and magnetic properties but are prone to rust if not properly coated. The tin coating enhances the can's resistance to acids and moisture, making tin-plated steel cans ideal for preserving food products without compromising safety or quality.

Manufacturing Process Differences

Tin cans utilize a steel base coated with a thin layer of tin through electroplating, enhancing corrosion resistance and food safety, while steel cans may be made from carbon steel or stainless steel without tin coating. The manufacturing process for tin cans involves tinning the steel sheets before forming, which adds extra steps such as electroplating and drying, whereas steel cans typically undergo stamping and forming directly from raw steel sheets. These differences impact production speed, cost, and the longevity of the final product, with tin cans often preferred for their superior rust prevention in food packaging.

Durability and Strength Comparison

Tin cans offer corrosion resistance due to their thin tin coating, but steel cans provide superior durability and strength for heavy-duty storage and transportation needs. Steel cans withstand higher pressure and resist deformation better, making them ideal for preserving products under harsh conditions. The reinforced steel structure of steel cans ensures longer shelf life and protection compared to tin's limited durability.

Corrosion Resistance: Tin Cans vs Steel Cans

Tin cans exhibit superior corrosion resistance compared to steel cans due to their tin plating, which acts as a protective barrier against moisture and air, preventing rust formation. Steel cans, while strong and durable, are more prone to corrosion when the protective coatings are damaged or degraded over time. This inherent corrosion resistance makes tin cans ideal for preserving food quality and extending shelf life under various storage conditions.

Cost Analysis of Tin and Steel Cans

Tin cans generally incur higher raw material costs due to tin's relative scarcity and price volatility compared to steel. Steel cans benefit from lower production expenses and widespread availability, making them more cost-effective for large-scale packaging. The overall cost analysis favors steel cans for budget-sensitive applications, while tin cans may be preferred when corrosion resistance justifies the premium.

Safety and Food Preservation Qualities

Tin cans offer superior corrosion resistance due to their tin coating, which prevents rust and contamination, enhancing food safety during storage. Steel cans, although stronger structurally, are prone to rust without protective coatings, potentially compromising food quality and safety. The tin coating also provides an effective barrier against oxygen and moisture, preserving the freshness and flavor of canned foods longer than uncoated steel cans.

Environmental Impact and Recycling

Tin cans offer a lower environmental impact compared to steel cans due to their lighter weight, which reduces transportation emissions and energy consumption during production. Tin is highly recyclable, with recycling processes requiring less energy and producing fewer greenhouse gases than steel can recycling. The superior corrosion resistance of tin-coated cans extends product shelf life, further minimizing waste and resource usage.

Applications in the Packaging Industry

Tin cans are widely used in the packaging industry due to their excellent corrosion resistance and food safety, making them ideal for preserving canned goods and beverages. Steel cans, often coated with tin or other protective layers, offer superior strength and durability, which is essential for packaging heavy or industrial products. Both materials are recyclable, but tin's non-toxic properties give it a distinct advantage in packaging perishable food items where contamination must be avoided.

Consumer Preferences and Market Trends

Tin cans are highly favored by consumers for their corrosion resistance and superior food preservation qualities compared to steel cans, which often require additional coatings to prevent rust. Market trends indicate a growing demand for tin cans in the food packaging industry due to increased awareness of product safety and sustainability. Steel cans, while more cost-effective, face declining consumer preference in premium food segments where tin's durability and non-reactive properties provide a competitive edge.

Future Innovations in Can Materials

Future innovations in can materials emphasize lightweight tin alloys and hybrid coatings that combine corrosion resistance with recyclability, surpassing traditional steel cans. Advances in nanocoatings and biodegradable linings enhance sustainability and food safety, positioning tin cans as a more eco-friendly alternative. Research into composite structures integrates tin with polymers to improve strength-to-weight ratios while reducing environmental impact.

Tin cans vs Steel cans Infographic

materialdif.com

materialdif.com