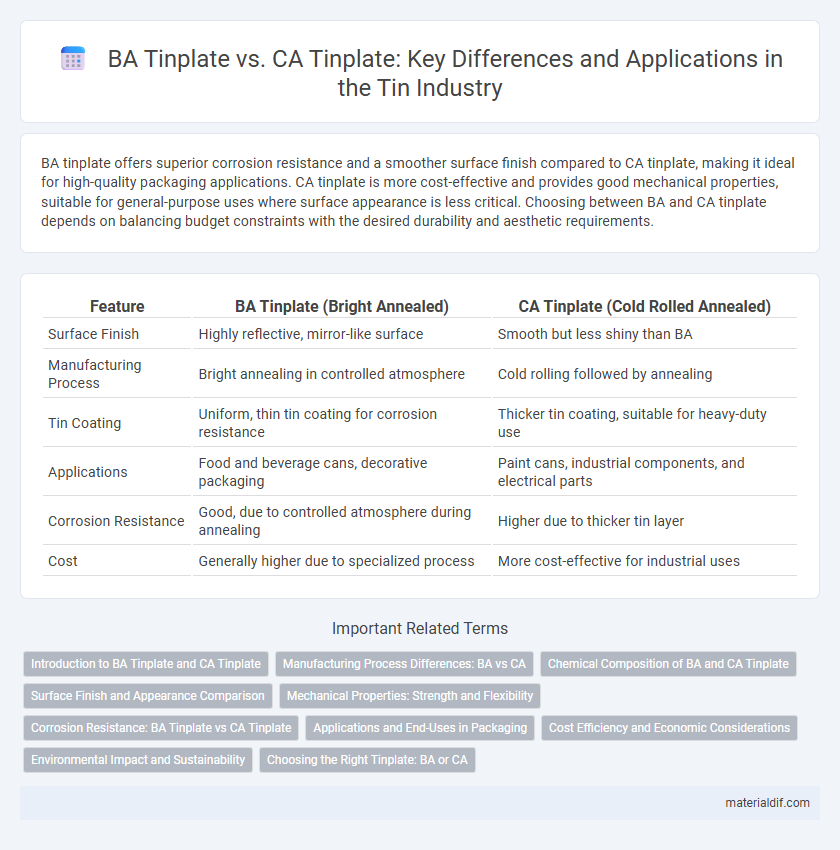

BA tinplate offers superior corrosion resistance and a smoother surface finish compared to CA tinplate, making it ideal for high-quality packaging applications. CA tinplate is more cost-effective and provides good mechanical properties, suitable for general-purpose uses where surface appearance is less critical. Choosing between BA and CA tinplate depends on balancing budget constraints with the desired durability and aesthetic requirements.

Table of Comparison

| Feature | BA Tinplate (Bright Annealed) | CA Tinplate (Cold Rolled Annealed) |

|---|---|---|

| Surface Finish | Highly reflective, mirror-like surface | Smooth but less shiny than BA |

| Manufacturing Process | Bright annealing in controlled atmosphere | Cold rolling followed by annealing |

| Tin Coating | Uniform, thin tin coating for corrosion resistance | Thicker tin coating, suitable for heavy-duty use |

| Applications | Food and beverage cans, decorative packaging | Paint cans, industrial components, and electrical parts |

| Corrosion Resistance | Good, due to controlled atmosphere during annealing | Higher due to thicker tin layer |

| Cost | Generally higher due to specialized process | More cost-effective for industrial uses |

Introduction to BA Tinplate and CA Tinplate

BA Tinplate, or Bright Annealed Tinplate, undergoes an annealing process in a bright atmosphere, resulting in a smooth, reflective surface ideal for high-quality printing and food packaging. CA Tinplate, or Continuous Annealed Tinplate, is produced through continuous annealing, offering consistent mechanical properties and excellent formability for can body manufacturing. Both types provide corrosion resistance and are widely used in the packaging industry depending on specific application requirements.

Manufacturing Process Differences: BA vs CA

BA tinplate is produced by bright annealing, where the steel strip undergoes annealing in a controlled atmosphere to maintain a shiny, smooth surface before tin coating, enhancing corrosion resistance. CA tinplate involves a continuous annealing process in a reducing atmosphere, resulting in a matte finish with improved mechanical properties suited for deep drawing applications. The key manufacturing difference lies in the annealing environment and surface finish control, directly impacting the tinplate's appearance and forming characteristics.

Chemical Composition of BA and CA Tinplate

BA tinplate features a chemical composition with low carbon content, typically below 0.02%, and minimal manganese and silicon, enhancing its ductility and corrosion resistance. CA tinplate, on the other hand, contains slightly higher carbon levels around 0.05%, along with increased manganese and silicon percentages to improve strength and formability. Both types maintain a thin, uniform tin coating essential for food-grade packaging, but their base steel chemical differences tailor their mechanical properties for specific applications.

Surface Finish and Appearance Comparison

BA tinplate features a bright, smooth surface finish achieved through final cold rolling, resulting in a highly reflective appearance suitable for premium packaging applications. CA tinplate, produced via a controlled annealing process, offers a duller, less reflective surface with a matte finish, making it ideal for labeling where reduced glare is preferred. The choice between BA and CA tinplate depends on specific aesthetic requirements and the desired surface texture for tin packaging products.

Mechanical Properties: Strength and Flexibility

BA tinplate exhibits higher tensile strength due to its bright annealed finish, making it ideal for rigid packaging applications requiring durability. CA tinplate offers superior flexibility and elongation, resulting from its cold-rolled annealed process, which enhances formability for complex shapes. The choice between BA and CA tinplate depends on balancing strength requirements with the need for material flexibility.

Corrosion Resistance: BA Tinplate vs CA Tinplate

BA tinplate, produced through a bright annealing process, offers superior corrosion resistance due to its smooth, uniform surface that enhances the protective tin layer's adherence. CA tinplate, created via continuous annealing, tends to have a slightly rougher surface, which can result in comparatively lower corrosion resistance under harsh environmental conditions. The choice between BA and CA tinplates depends on the application's specific exposure to moisture and corrosive agents, with BA tinplate generally preferred for high-corrosion-resistance requirements.

Applications and End-Uses in Packaging

BA tinplate offers a bright, smooth surface ideal for high-quality food and beverage cans, ensuring excellent printability and corrosion resistance. CA tinplate, with a matte finish and cost-effective production, suits packaging for products like paint cans, aerosol containers, and general industrial uses. Both types enhance product protection, but BA tinplate is preferred in premium packaging where visual appeal and hygienic standards are critical.

Cost Efficiency and Economic Considerations

BA tinplate offers superior surface finish and strength but typically comes at a higher manufacturing cost due to its additional annealing process and reduced carbon content. CA tinplate, while having a slightly lower aesthetic quality and mechanical properties, provides cost efficiency through simpler production methods and lower raw material expenses. Choosing between BA and CA tinplate depends on balancing budget constraints with the specific strength and appearance requirements of the final product.

Environmental Impact and Sustainability

BA tinplate, produced through bright annealing, typically has a smoother surface requiring less coating material, thereby reducing waste and environmental impact during manufacturing. CA tinplate, created via continuous annealing, involves higher energy consumption and chemical use, resulting in a relatively larger carbon footprint. Choosing BA tinplate enhances sustainability by minimizing resource use and facilitating more efficient recycling processes in the packaging industry.

Choosing the Right Tinplate: BA or CA

BA tinplate offers a bright, reflective finish with excellent surface smoothness, making it ideal for high-end packaging and decorative uses. CA tinplate, known for its cost-effectiveness and good corrosion resistance, suits general packaging applications where surface appearance is less critical. Selecting between BA and CA tinplate depends on balancing budget constraints with aesthetic and performance requirements specific to the end product.

BA Tinplate vs CA Tinplate Infographic

materialdif.com

materialdif.com