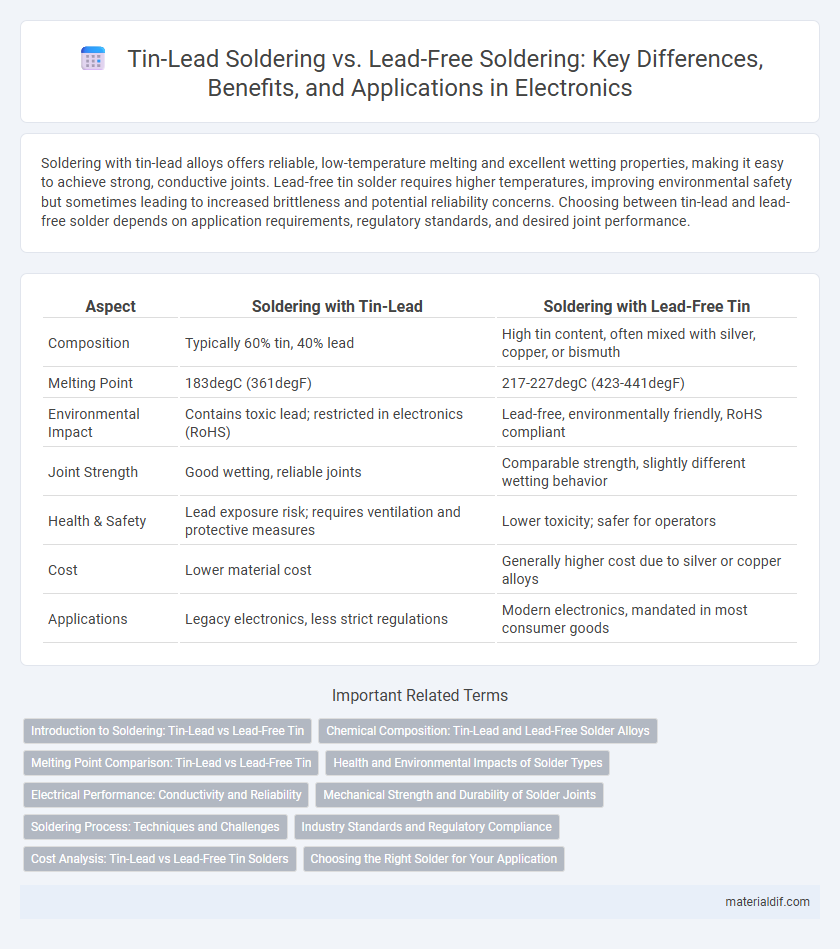

Soldering with tin-lead alloys offers reliable, low-temperature melting and excellent wetting properties, making it easy to achieve strong, conductive joints. Lead-free tin solder requires higher temperatures, improving environmental safety but sometimes leading to increased brittleness and potential reliability concerns. Choosing between tin-lead and lead-free solder depends on application requirements, regulatory standards, and desired joint performance.

Table of Comparison

| Aspect | Soldering with Tin-Lead | Soldering with Lead-Free Tin |

|---|---|---|

| Composition | Typically 60% tin, 40% lead | High tin content, often mixed with silver, copper, or bismuth |

| Melting Point | 183degC (361degF) | 217-227degC (423-441degF) |

| Environmental Impact | Contains toxic lead; restricted in electronics (RoHS) | Lead-free, environmentally friendly, RoHS compliant |

| Joint Strength | Good wetting, reliable joints | Comparable strength, slightly different wetting behavior |

| Health & Safety | Lead exposure risk; requires ventilation and protective measures | Lower toxicity; safer for operators |

| Cost | Lower material cost | Generally higher cost due to silver or copper alloys |

| Applications | Legacy electronics, less strict regulations | Modern electronics, mandated in most consumer goods |

Introduction to Soldering: Tin-Lead vs Lead-Free Tin

Soldering with tin-lead alloys typically offers lower melting points around 183degC, enabling easier flow and strong mechanical bonds, but raises environmental and health concerns due to lead content. Lead-free tin solder, commonly comprised of tin, silver, and copper (SAC alloys), melts at higher temperatures near 217-221degC and complies with RoHS regulations, providing better corrosion resistance and electrical performance. Selecting between tin-lead and lead-free solder depends on application-specific requirements involving durability, regulatory compliance, and thermal profiles.

Chemical Composition: Tin-Lead and Lead-Free Solder Alloys

Tin-lead solder alloys typically consist of approximately 60% tin and 40% lead, providing a low melting point around 183degC and excellent wetting properties ideal for traditional electronics. Lead-free solder alloys commonly replace lead with metals such as silver, copper, and bismuth, with compositions like SAC305 (96.5% tin, 3% silver, 0.5% copper) offering higher melting points near 217degC and improved environmental compliance. The chemical composition significantly influences the solder joint's mechanical strength, thermal fatigue resistance, and reliability in various electronic applications.

Melting Point Comparison: Tin-Lead vs Lead-Free Tin

Tin-lead solder typically melts at a lower temperature, around 183degC (361degF), providing easier flow and quicker bonding compared to lead-free alternatives. Lead-free tin solders, commonly composed of tin-copper or tin-silver-copper alloys, have higher melting points ranging from 217degC to 227degC (423degF to 441degF), requiring more heat for effective soldering. This difference in melting points affects processing temperatures, equipment calibration, and the thermal stress applied to electronic components during assembly.

Health and Environmental Impacts of Solder Types

Soldering with tin-lead alloys poses significant health risks due to lead's toxicity, including potential neurological damage and environmental contamination through improper disposal. Lead-free tin solder, often composed of tin-copper or tin-silver-copper alloys, reduces these health hazards by eliminating lead but may require higher temperatures, impacting energy consumption and component longevity. Environmentally, lead-free solder minimizes soil and water pollution, supporting regulatory compliance such as RoHS directives, while tin-lead solder remains restricted or banned in many applications.

Electrical Performance: Conductivity and Reliability

Soldering with tin-lead alloy offers superior electrical conductivity, typically around 15.9 MS/m, ensuring reliable signal transmission in sensitive electronic circuits. Lead-free tin solder, often composed of tin-copper-silver or tin-silver-copper alloys, exhibits slightly lower conductivity, generally near 9-13 MS/m, which can impact high-frequency performance. Despite reduced conductivity, lead-free solders improve long-term reliability by resisting tin whisker growth and meeting RoHS compliance standards.

Mechanical Strength and Durability of Solder Joints

Soldering with tin-lead alloys typically offers superior mechanical strength and durability in solder joints due to the alloy's lower melting point, optimal wettability, and ductile microstructure, which reduces the risk of cracks under thermal cycling. Lead-free tin solder joints, often composed of tin-silver-copper (SAC) alloys, exhibit higher melting points and increased brittleness, potentially leading to decreased mechanical reliability, though advances in alloy formulations have improved their performance. The choice between tin-lead and lead-free tin soldering impacts the long-term integrity of electronic assemblies, with tin-lead solder remaining preferable for high-stress environments despite regulatory pressures to adopt lead-free alternatives.

Soldering Process: Techniques and Challenges

Soldering with tin-lead alloys offers a lower melting point around 183degC, facilitating easier flow and stronger joint formation in traditional electronic assemblies, while lead-free tin solder requires elevated temperatures typically above 217degC, posing challenges such as increased thermal stress on components. Lead-free soldering often involves techniques like reflow and wave soldering that must be precisely controlled to prevent defects such as tombstoning and voids, which are less frequent in tin-lead processes. The transition to lead-free solder demands careful adjustment in thermal profiles and flux selection to ensure reliable wetting and joint integrity in compliance with RoHS regulations.

Industry Standards and Regulatory Compliance

Soldering with tin-lead alloys remains prevalent in specific industries due to its reliable wetting properties and lower melting point, aligning with traditional industry standards like MIL-STD-2000. However, lead-free tin solder, typically composed of tin, silver, and copper (SAC alloys), complies with strict regulatory frameworks such as the RoHS directive and REACH regulations, which restrict hazardous substances in electronic manufacturing. The shift to lead-free solder mandates adherence to updated industry standards including IPC J-STD-006C, ensuring environmental safety without compromising joint integrity.

Cost Analysis: Tin-Lead vs Lead-Free Tin Solders

Tin-lead solders generally offer lower material costs and superior wetting properties, resulting in reduced production time and fewer defects, which can lower overall manufacturing expenses. Lead-free tin solders, while more expensive due to higher tin content and stricter environmental regulations, incur additional costs from higher melting temperatures and potential equipment modifications. Evaluating total cost analysis requires balancing upfront material savings of tin-lead solder against longer-term regulatory compliance and reliability benefits of lead-free alternatives.

Choosing the Right Solder for Your Application

Choosing the right solder for your application depends on factors like operating temperature, mechanical strength, and environmental regulations. Tin-lead solder offers lower melting points and better wetting properties, ideal for delicate electronic components, while lead-free tin solder complies with RoHS directives, providing higher thermal resistance and improved mechanical durability. Evaluating the trade-offs between performance and regulatory compliance ensures optimal solder joint reliability and long-term device functionality.

Soldering with tin-lead vs Soldering with lead-free tin Infographic

materialdif.com

materialdif.com