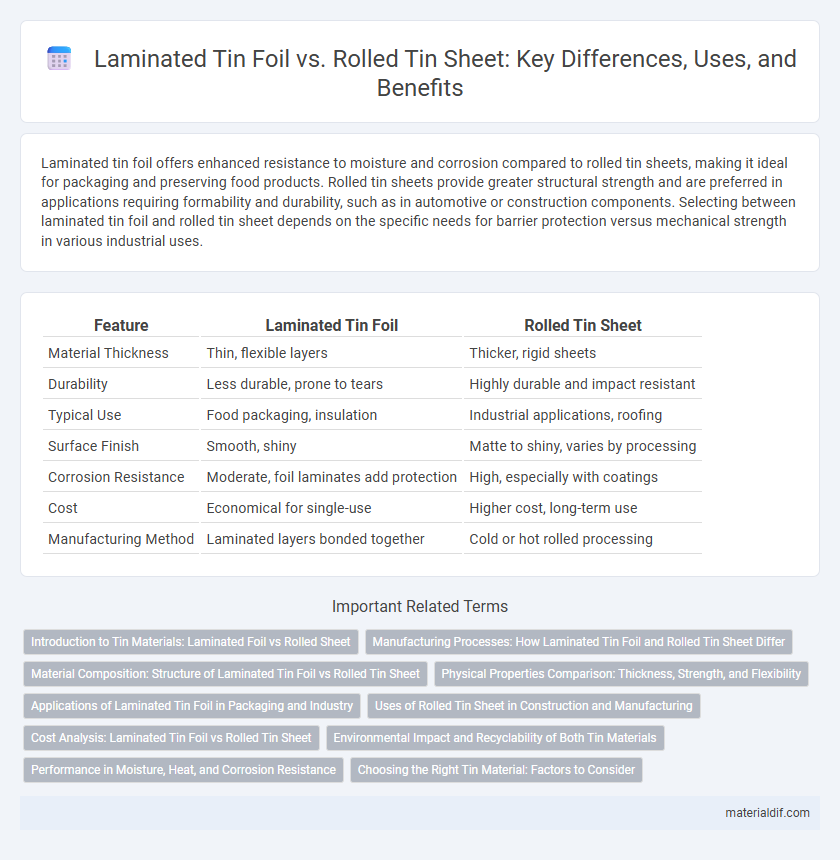

Laminated tin foil offers enhanced resistance to moisture and corrosion compared to rolled tin sheets, making it ideal for packaging and preserving food products. Rolled tin sheets provide greater structural strength and are preferred in applications requiring formability and durability, such as in automotive or construction components. Selecting between laminated tin foil and rolled tin sheet depends on the specific needs for barrier protection versus mechanical strength in various industrial uses.

Table of Comparison

| Feature | Laminated Tin Foil | Rolled Tin Sheet |

|---|---|---|

| Material Thickness | Thin, flexible layers | Thicker, rigid sheets |

| Durability | Less durable, prone to tears | Highly durable and impact resistant |

| Typical Use | Food packaging, insulation | Industrial applications, roofing |

| Surface Finish | Smooth, shiny | Matte to shiny, varies by processing |

| Corrosion Resistance | Moderate, foil laminates add protection | High, especially with coatings |

| Cost | Economical for single-use | Higher cost, long-term use |

| Manufacturing Method | Laminated layers bonded together | Cold or hot rolled processing |

Introduction to Tin Materials: Laminated Foil vs Rolled Sheet

Laminated tin foil and rolled tin sheet are two primary forms of tin materials used across various industries, offering distinct structural and functional properties. Laminated tin foil consists of multiple layers of tin bonded with other materials, providing enhanced flexibility, corrosion resistance, and lightweight characteristics ideal for packaging and insulation. Rolled tin sheet, produced by rolling solid tin ingots, features greater thickness, strength, and durability, making it suitable for applications requiring mechanical robustness and thermal conductivity.

Manufacturing Processes: How Laminated Tin Foil and Rolled Tin Sheet Differ

Laminated tin foil is produced by bonding thin layers of tin to a substrate such as paper or plastic, using heat and pressure to create a flexible, multi-layered material ideal for packaging and insulation. Rolled tin sheets are manufactured through a metal rolling process where bulk tin ingots are passed through rollers to achieve uniform thickness and a solid, durable form suitable for industrial applications. The key manufacturing difference lies in laminated foil's composite layering versus rolled sheet's deformation of pure tin metal.

Material Composition: Structure of Laminated Tin Foil vs Rolled Tin Sheet

Laminated tin foil consists of multiple ultra-thin layers of tin combined with an adhesive or substrate, enhancing flexibility and barrier properties for packaging applications. Rolled tin sheets are produced by mechanically rolling solid tin ingots into uniform thickness, resulting in a dense, single-layered metallic structure ideal for industrial uses. The layered structure of laminated tin foil provides improved mechanical strength and corrosion resistance compared to the monolithic, homogeneous composition of rolled tin sheets.

Physical Properties Comparison: Thickness, Strength, and Flexibility

Laminated tin foil typically has a thickness ranging from 0.01 to 0.05 mm, offering exceptional flexibility and moderate tensile strength, making it ideal for packaging applications requiring delicate handling. Rolled tin sheets are significantly thicker, usually between 0.2 to 0.5 mm, providing enhanced strength and rigidity with less flexibility, suitable for structural and industrial uses. The choice between the two depends on the required balance of strength and pliability, as laminated foil excels in flexibility while rolled sheets dominate in durability.

Applications of Laminated Tin Foil in Packaging and Industry

Laminated tin foil offers superior barrier properties against moisture, oxygen, and light, making it ideal for food packaging, pharmaceuticals, and cosmetics to preserve product freshness and extend shelf life. Its lightweight and flexible nature facilitates easy wrapping and sealing in industrial applications, including electronics insulation and decorative laminates. The combination of corrosion resistance and printability of laminated tin foil enhances branding opportunities and longevity in packaging solutions.

Uses of Rolled Tin Sheet in Construction and Manufacturing

Rolled tin sheets serve crucial roles in construction and manufacturing due to their durability, malleability, and corrosion resistance. In construction, they are widely used for roofing, gutters, and flashing to protect buildings from water damage. Manufacturing industries utilize rolled tin sheets for producing tin-plated steel parts, electrical components, and packaging materials, thanks to their excellent solderability and resistance to oxidation.

Cost Analysis: Laminated Tin Foil vs Rolled Tin Sheet

Laminated tin foil generally incurs higher production costs due to the multilayer bonding process, impacting its market price compared to rolled tin sheet, which benefits from more straightforward manufacturing and lower raw material usage. Cost efficiency varies with application scale; laminated tin foil offers superior barrier properties, potentially reducing overall material consumption despite higher unit costs. Evaluating total life-cycle expenses in packaging or industrial use reveals laminated foil's investment may offset by enhanced durability, whereas rolled tin sheet remains the cost-effective choice for applications prioritizing simplicity and budget.

Environmental Impact and Recyclability of Both Tin Materials

Laminated tin foil and rolled tin sheet differ significantly in environmental impact and recyclability; laminated tin foil often contains multiple layers including plastics that hinder recycling processes, whereas rolled tin sheets are typically composed of pure tin, allowing for more efficient recycling and reduced waste. The production of laminated tin foil involves higher energy consumption and generates more complex waste streams due to the bonding of various materials, while rolled tin sheet manufacturing is more straightforward, resulting in lower carbon emissions. Recyclers prioritize rolled tin sheets for material recovery because pure tin can be remelted and reused without contamination, promoting sustainability within the metal industry.

Performance in Moisture, Heat, and Corrosion Resistance

Laminated tin foil exhibits superior moisture resistance due to its tightly bonded layers that prevent water penetration, making it ideal for packaging sensitive products. Rolled tin sheets demonstrate enhanced heat resistance, maintaining structural integrity at elevated temperatures typically encountered in industrial applications. In terms of corrosion resistance, laminated tin foil offers better protection against oxidation through its layered design, whereas rolled tin sheets require additional coatings for comparable durability.

Choosing the Right Tin Material: Factors to Consider

When choosing between laminated tin foil and rolled tin sheet, consider factors such as thickness, flexibility, and application requirements. Laminated tin foil offers superior barrier properties and is ideal for packaging sensitive products, while rolled tin sheets provide greater structural strength for industrial uses. Cost efficiency, corrosion resistance, and ease of fabrication are also critical in selecting the appropriate tin material.

Laminated Tin Foil vs Rolled Tin Sheet Infographic

materialdif.com

materialdif.com