Soldering with tin involves joining metal parts using a filler metal with a melting point below 450degC, creating a strong but flexible bond ideal for delicate electronics. Brazing with tin uses higher temperatures above 450degC to melt the filler metal, producing a more durable and heat-resistant joint suitable for structural applications. Both techniques rely on tin's excellent wetting properties to ensure reliable adhesion and corrosion resistance.

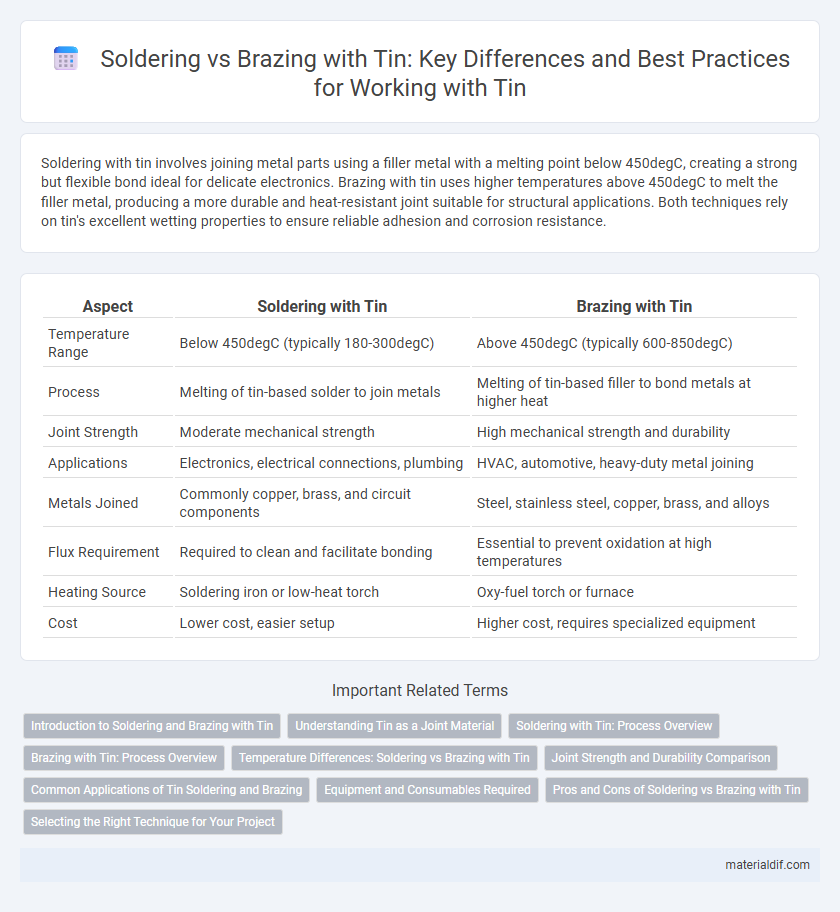

Table of Comparison

| Aspect | Soldering with Tin | Brazing with Tin |

|---|---|---|

| Temperature Range | Below 450degC (typically 180-300degC) | Above 450degC (typically 600-850degC) |

| Process | Melting of tin-based solder to join metals | Melting of tin-based filler to bond metals at higher heat |

| Joint Strength | Moderate mechanical strength | High mechanical strength and durability |

| Applications | Electronics, electrical connections, plumbing | HVAC, automotive, heavy-duty metal joining |

| Metals Joined | Commonly copper, brass, and circuit components | Steel, stainless steel, copper, brass, and alloys |

| Flux Requirement | Required to clean and facilitate bonding | Essential to prevent oxidation at high temperatures |

| Heating Source | Soldering iron or low-heat torch | Oxy-fuel torch or furnace |

| Cost | Lower cost, easier setup | Higher cost, requires specialized equipment |

Introduction to Soldering and Brazing with Tin

Soldering with tin involves joining metals by melting a tin-based filler metal at temperatures typically below 450degC, creating a strong electrical and mechanical bond ideal for electronics and delicate components. Brazing with tin uses a higher temperature process, usually above 450degC, where a tin alloy filler metal flows into the joint by capillary action, producing a durable and heat-resistant connection suited for plumbing and metalwork. Both techniques rely on the excellent wettability and corrosion resistance of tin alloys, making them essential in various industrial and manufacturing applications.

Understanding Tin as a Joint Material

Soldering with tin involves melting a tin-based alloy below 450degC to join metal parts without melting the base metals, creating a mechanically and electrically conductive bond ideal for delicate electronic components. Brazing with tin requires higher temperatures, typically above 450degC but below the melting point of the base metals, producing stronger joints suitable for heavier mechanical stresses by allowing the filler metal to flow into the joint via capillary action. Understanding tin's melting properties and compatibility with various base metals is crucial in selecting the appropriate joining method, as soldering emphasizes electrical conductivity and low thermal impact, while brazing prioritizes joint strength and durability.

Soldering with Tin: Process Overview

Soldering with tin involves melting a tin-based alloy at temperatures typically below 450degC to join metal components, creating a strong electrical and mechanical bond without melting the base metals. The process requires flux to prevent oxidation and ensure proper wetting of the surfaces, enhancing joint reliability. Common applications include electronics assembly and plumbing, where precise, low-heat connections are critical.

Brazing with Tin: Process Overview

Brazing with tin involves heating a tin-based filler metal above 450degC to join two base metals without melting them, creating a strong, corrosion-resistant bond. This process allows for precise control over joint strength and is ideal for delicate components requiring minimal thermal distortion. Compared to soldering, brazing with tin provides higher mechanical strength and better suitability for high-temperature applications.

Temperature Differences: Soldering vs Brazing with Tin

Soldering with tin typically occurs at temperatures below 450degC, making it suitable for delicate electronic components and circuitry. Brazing with tin demands higher temperatures, generally ranging from 450degC to 600degC, providing stronger mechanical bonds suitable for heavy-duty applications. The significant temperature difference impacts joint strength, material compatibility, and thermal stress during assembly.

Joint Strength and Durability Comparison

Soldering with tin produces joints with lower melting points, resulting in moderate strength suitable for delicate electronics, whereas brazing with tin requires higher temperatures, creating stronger and more durable joints ideal for structural applications. The metallurgical bond formed in brazing offers enhanced resistance to mechanical stress and thermal cycling compared to the softer bonds formed in soldering. Thus, tin-based brazed joints typically outperform tin-soldered joints in strength and longevity under demanding conditions.

Common Applications of Tin Soldering and Brazing

Tin soldering is commonly used in electronics manufacturing for joining delicate components on printed circuit boards due to its low melting point and excellent electrical conductivity. Brazing with tin, often combined with other metals like copper or silver, is favored in plumbing and HVAC systems to create strong, leak-proof joints capable of withstanding higher temperatures and mechanical stress. Both techniques leverage tin's corrosion resistance, but soldering suits fine, precision work while brazing handles structural connections in metal fabrication.

Equipment and Consumables Required

Soldering with tin primarily requires a soldering iron, flux, and tin-based solder wire, which melts at lower temperatures suitable for delicate electronics or thin metals. Brazing with tin demands a torch or furnace capable of higher heat, specialized flux, and thicker tin-based filler rods or wire to join stronger metal assemblies. Both processes involve flux to prevent oxidation, but brazing equipment is generally more robust to ensure proper flow and adhesion of the tin alloy at elevated temperatures.

Pros and Cons of Soldering vs Brazing with Tin

Soldering with tin offers lower temperature application, reducing heat damage to delicate components and enabling precise electronic connections, while brazing with tin requires higher temperatures, creating stronger, more durable joints suitable for heavy-duty and high-stress environments. Soldered joints typically have lower mechanical strength and are more susceptible to thermal fatigue compared to brazed joints, which provide superior load-bearing capacity and corrosion resistance. However, soldering is faster and more cost-effective for small-scale or intricate assemblies, whereas brazing demands more complex equipment and longer processing times.

Selecting the Right Technique for Your Project

Soldering with tin is ideal for delicate electronics and thin metals due to its lower melting point, around 183degC, ensuring minimal heat damage while creating strong electrical connections. Brazing with tin alloys, which melt above 450degC, provides superior mechanical strength and is better suited for joining thicker metals and structural components. Understanding the thermal requirements, joint strength, and material compatibility is crucial for selecting the appropriate tin-based joining technique to optimize project durability and performance.

Soldering with tin vs Brazing with tin Infographic

materialdif.com

materialdif.com