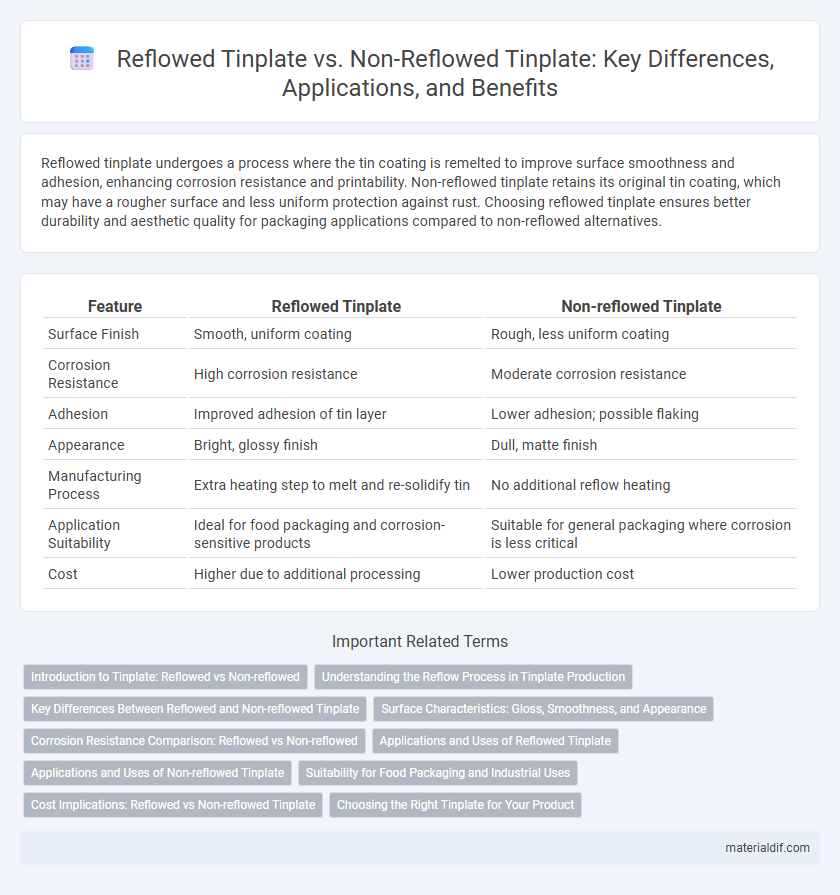

Reflowed tinplate undergoes a process where the tin coating is remelted to improve surface smoothness and adhesion, enhancing corrosion resistance and printability. Non-reflowed tinplate retains its original tin coating, which may have a rougher surface and less uniform protection against rust. Choosing reflowed tinplate ensures better durability and aesthetic quality for packaging applications compared to non-reflowed alternatives.

Table of Comparison

| Feature | Reflowed Tinplate | Non-reflowed Tinplate |

|---|---|---|

| Surface Finish | Smooth, uniform coating | Rough, less uniform coating |

| Corrosion Resistance | High corrosion resistance | Moderate corrosion resistance |

| Adhesion | Improved adhesion of tin layer | Lower adhesion; possible flaking |

| Appearance | Bright, glossy finish | Dull, matte finish |

| Manufacturing Process | Extra heating step to melt and re-solidify tin | No additional reflow heating |

| Application Suitability | Ideal for food packaging and corrosion-sensitive products | Suitable for general packaging where corrosion is less critical |

| Cost | Higher due to additional processing | Lower production cost |

Introduction to Tinplate: Reflowed vs Non-reflowed

Reflowed tinplate is created by melting the tin coating onto the steel substrate, enhancing adhesion and providing superior corrosion resistance compared to non-reflowed tinplate, where the tin layer is simply electroplated without melting. The reflow process results in a smoother, more uniform finish that improves solderability and reduces cracking, making it ideal for packaging applications requiring durability. Non-reflowed tinplate, while cost-effective, often exhibits weaker bonding between tin and steel, leading to inferior protection and limited use in high-demand environments.

Understanding the Reflow Process in Tinplate Production

Reflowed tinplate undergoes a controlled heating process that melts the applied tin coating, creating a smoother and more uniform surface compared to non-reflowed tinplate, which retains a rougher, matte finish from the initial electroplating. The reflow process enhances corrosion resistance and improves the adhesion of subsequent coatings or inks, essential for packaging applications requiring durability and high-quality printability. Non-reflowed tinplate is typically used where cost efficiency is prioritized over optimal surface properties, making the reflow step a critical factor in specialized tinplate production.

Key Differences Between Reflowed and Non-reflowed Tinplate

Reflowed tinplate undergoes a controlled reheating process that smooths the tin coating, enhancing surface uniformity and adhesion, whereas non-reflowed tinplate retains a matte, rougher finish due to the absence of this heat treatment. Reflowing improves corrosion resistance and provides a more consistent substrate for printing and lacquering, critical in food and beverage packaging applications. Non-reflowed tinplate, while offering a lower cost, may exhibit increased susceptibility to surface defects and reduced aesthetic quality.

Surface Characteristics: Gloss, Smoothness, and Appearance

Reflowed tinplate exhibits superior gloss and smoothness due to the molten tin layer that creates a uniform, mirror-like finish, enhancing visual appeal and corrosion resistance. Non-reflowed tinplate often has a matte or slightly irregular surface texture, lacking the continuous molten tin coating, which can result in lower reflectivity and a less polished appearance. The reflow process significantly improves surface characteristics by reducing surface defects and increasing tin adhesion, making reflowed tinplate preferred for premium packaging applications.

Corrosion Resistance Comparison: Reflowed vs Non-reflowed

Reflowed tinplate exhibits superior corrosion resistance compared to non-reflowed tinplate due to the homogenized tin coating formed during the reflow process, which eliminates voids and sharp edges that can accelerate corrosion. The reflowed surface enhances adhesion of protective layers and reduces susceptibility to localized corrosion, especially in humid or saline environments. Non-reflowed tinplate typically has a rougher surface with micro-cracks, making it more vulnerable to oxidation and corrosion over time.

Applications and Uses of Reflowed Tinplate

Reflowed tinplate is widely used in food and beverage packaging due to its enhanced corrosion resistance and improved weldability, making it ideal for cans and containers requiring airtight seals. Its smooth, defect-free surface ensures superior printability and coating adhesion, essential for high-quality labeling and branding in consumer products. Manufacturing industries utilize reflowed tinplate for automotive fuel tanks and household appliances, benefiting from its durability and resistance to chemical exposure.

Applications and Uses of Non-reflowed Tinplate

Non-reflowed tinplate is commonly used in applications requiring strong corrosion resistance and excellent mechanical strength, such as food and beverage cans, paint cans, and aerosol containers. Its non-reflowed coating maintains superior adhesion and prevents brittleness, making it ideal for deep-drawn or welded can manufacturing. Non-reflowed tinplate is preferred in industries demanding high durability and long-term protection against environmental factors.

Suitability for Food Packaging and Industrial Uses

Reflowed tinplate offers superior corrosion resistance and uniform coating thickness, making it ideal for food packaging where hygiene and protection against contamination are critical. Non-reflowed tinplate, with its lower surface smoothness and uneven tin distribution, suits industrial applications that require less stringent cleanliness standards but benefit from enhanced mechanical strength. The choice depends on the specific demands of preserving food safety or providing durability in manufacturing environments.

Cost Implications: Reflowed vs Non-reflowed Tinplate

Reflowed tinplate typically incurs higher manufacturing costs due to the additional heating process required to melt and redistribute the tin coating, improving surface smoothness and corrosion resistance. Non-reflowed tinplate is less expensive as it bypasses this thermal step but may exhibit lower uniformity and increased susceptibility to oxidation. Cost implications for choosing reflowed versus non-reflowed tinplate depend on the desired product durability, with reflowed offering longer service life at a premium price.

Choosing the Right Tinplate for Your Product

Reflowed tinplate offers superior corrosion resistance and a smoother surface finish, making it ideal for high-quality packaging applications where durability is critical. Non-reflowed tinplate provides a cost-effective option with adequate protection for products with less stringent requirements or shorter shelf lives. Selecting the right tinplate depends on product sensitivity, budget constraints, and the need for enhanced barrier properties to ensure optimal performance.

Reflowed Tinplate vs Non-reflowed Tinplate Infographic

materialdif.com

materialdif.com