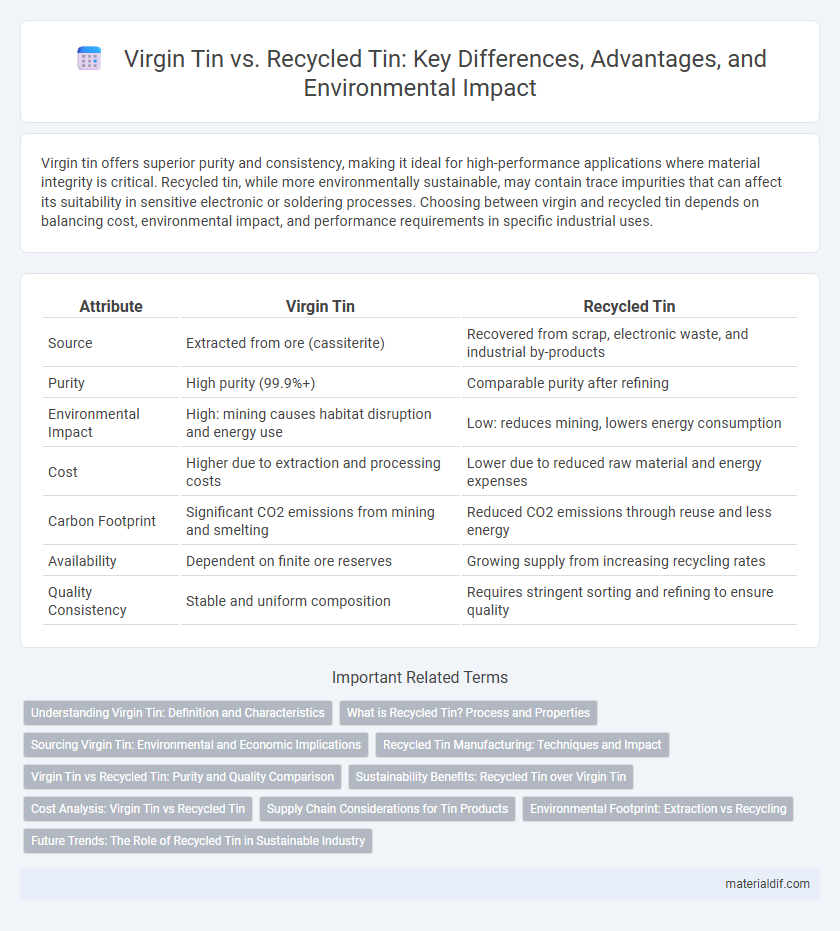

Virgin tin offers superior purity and consistency, making it ideal for high-performance applications where material integrity is critical. Recycled tin, while more environmentally sustainable, may contain trace impurities that can affect its suitability in sensitive electronic or soldering processes. Choosing between virgin and recycled tin depends on balancing cost, environmental impact, and performance requirements in specific industrial uses.

Table of Comparison

| Attribute | Virgin Tin | Recycled Tin |

|---|---|---|

| Source | Extracted from ore (cassiterite) | Recovered from scrap, electronic waste, and industrial by-products |

| Purity | High purity (99.9%+) | Comparable purity after refining |

| Environmental Impact | High: mining causes habitat disruption and energy use | Low: reduces mining, lowers energy consumption |

| Cost | Higher due to extraction and processing costs | Lower due to reduced raw material and energy expenses |

| Carbon Footprint | Significant CO2 emissions from mining and smelting | Reduced CO2 emissions through reuse and less energy |

| Availability | Dependent on finite ore reserves | Growing supply from increasing recycling rates |

| Quality Consistency | Stable and uniform composition | Requires stringent sorting and refining to ensure quality |

Understanding Virgin Tin: Definition and Characteristics

Virgin tin refers to tin extracted directly from primary ore sources, such as cassiterite, through mining and refining processes. It is characterized by its high purity and consistency, typically exceeding 99.9% tin content, making it ideal for applications requiring strict quality standards. Unlike recycled tin, virgin tin has not undergone previous use or processing, ensuring minimal contamination and superior metallurgical properties.

What is Recycled Tin? Process and Properties

Recycled tin is recovered from scrap materials such as electronic waste, tin cans, and industrial byproducts through processes like smelting and refining that remove impurities while preserving tin's ductility and corrosion resistance. The recycling process significantly reduces environmental impact by minimizing mining activities and energy consumption compared to virgin tin extraction. Properties of recycled tin closely match those of virgin tin, maintaining high purity levels typically above 99.8% for use in soldering, plating, and alloy production.

Sourcing Virgin Tin: Environmental and Economic Implications

Sourcing virgin tin involves mining cassiterite ore, which can lead to significant environmental impacts including habitat destruction, soil erosion, and water contamination. The economic implications include higher costs due to extensive extraction processes and regulatory compliance compared to recycled tin, but virgin tin often ensures consistent quality and supply for critical manufacturing sectors. Reducing reliance on virgin tin supports environmental sustainability and cost efficiency by minimizing resource depletion and promoting circular economy practices.

Recycled Tin Manufacturing: Techniques and Impact

Recycled tin manufacturing involves advanced techniques such as mechanical shredding, melting, and refining to recover high-purity tin from scrap materials, significantly reducing reliance on virgin tin mining. These processes lower environmental impact by minimizing energy consumption, reducing greenhouse gas emissions, and conserving natural resources compared to traditional extraction methods. The increased use of recycled tin supports sustainable supply chains in electronics, soldering, and packaging industries while promoting circular economy principles.

Virgin Tin vs Recycled Tin: Purity and Quality Comparison

Virgin tin is extracted directly from cassiterite ore, ensuring high purity levels typically above 99.9%, which is essential for applications requiring superior electrical conductivity and corrosion resistance. Recycled tin, sourced from scrap materials, may contain trace impurities that can affect its performance and necessitate refining processes to meet industry standards. The consistent quality and chemical stability of virgin tin make it preferable for high-precision uses, while recycled tin offers cost-effective and environmentally sustainable alternatives with slightly variable purity.

Sustainability Benefits: Recycled Tin over Virgin Tin

Recycled tin significantly reduces environmental impact by minimizing the need for mining, which lowers energy consumption and greenhouse gas emissions compared to virgin tin extraction. Utilizing recycled tin conserves natural resources and decreases waste in landfills, enhancing overall sustainability. This approach supports circular economy principles by promoting material reuse and reducing dependency on finite tin ore reserves.

Cost Analysis: Virgin Tin vs Recycled Tin

Virgin tin extraction involves higher operational and environmental costs due to mining, refining, and regulatory compliance, often making it more expensive than recycled tin. Recycled tin offers significant cost advantages by reducing raw material requirements and energy consumption, lowering overall production expenses. Market fluctuations in tin prices and recycling efficiency directly impact the cost-effectiveness of recycled tin compared to virgin tin.

Supply Chain Considerations for Tin Products

Virgin tin, sourced directly from mining operations, ensures a consistent quality and traceability but involves higher environmental and regulatory compliance costs throughout the supply chain. Recycled tin, recovered from electronic waste and other scrap materials, reduces reliance on mining, lowers carbon emissions, and supports circular economy initiatives, though it may present variability in purity and require more complex sorting and processing. Supply chain decisions must balance factors such as sustainability goals, cost efficiency, availability, and the stability of sourcing to optimize tin product performance and environmental impact.

Environmental Footprint: Extraction vs Recycling

Virgin tin extraction involves mining cassiterite, which leads to significant environmental degradation, including habitat destruction, soil erosion, and high energy consumption contributing to carbon emissions. Recycling tin markedly reduces the environmental footprint by lowering energy use by up to 80% and minimizing mining waste and associated pollutants. The closed-loop process of recycled tin supports sustainable resource management, reducing reliance on finite natural reserves and mitigating ecosystem impacts.

Future Trends: The Role of Recycled Tin in Sustainable Industry

Recycled tin is poised to play a critical role in the sustainable industry by reducing dependence on virgin tin mining, which often involves environmentally damaging extraction processes. Advances in recycling technologies are improving recovery rates, ensuring a steady supply of high-purity tin for electronics, packaging, and solder applications. Industry forecasts predict a significant increase in recycled tin usage driven by stringent environmental regulations and growing corporate commitments to circular economy principles.

Virgin Tin vs Recycled Tin Infographic

materialdif.com

materialdif.com