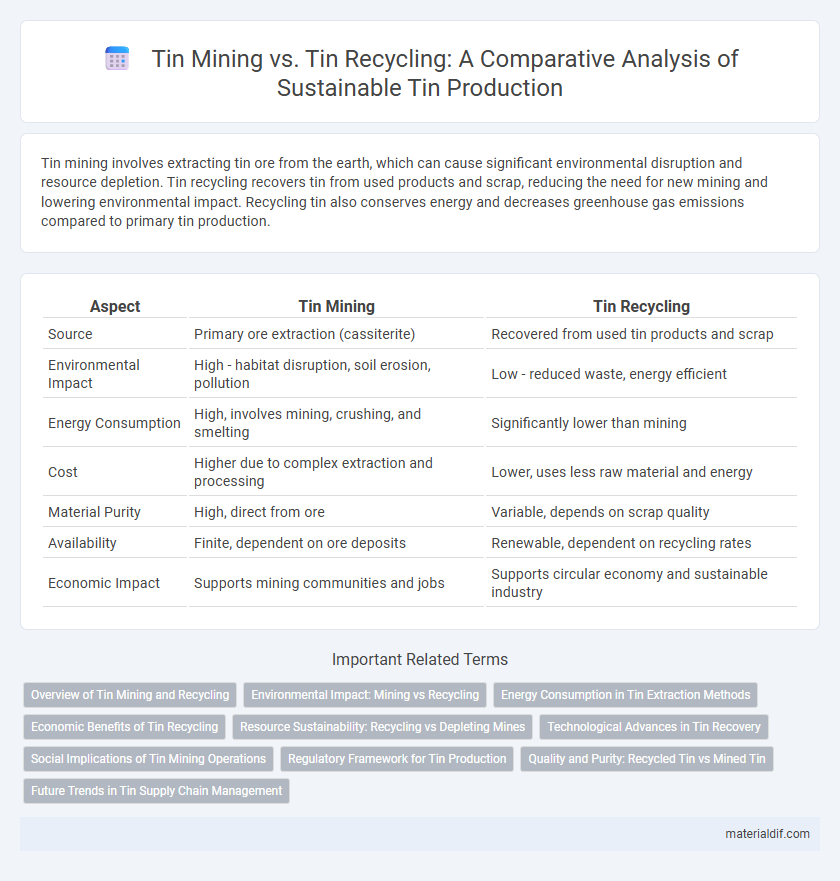

Tin mining involves extracting tin ore from the earth, which can cause significant environmental disruption and resource depletion. Tin recycling recovers tin from used products and scrap, reducing the need for new mining and lowering environmental impact. Recycling tin also conserves energy and decreases greenhouse gas emissions compared to primary tin production.

Table of Comparison

| Aspect | Tin Mining | Tin Recycling |

|---|---|---|

| Source | Primary ore extraction (cassiterite) | Recovered from used tin products and scrap |

| Environmental Impact | High - habitat disruption, soil erosion, pollution | Low - reduced waste, energy efficient |

| Energy Consumption | High, involves mining, crushing, and smelting | Significantly lower than mining |

| Cost | Higher due to complex extraction and processing | Lower, uses less raw material and energy |

| Material Purity | High, direct from ore | Variable, depends on scrap quality |

| Availability | Finite, dependent on ore deposits | Renewable, dependent on recycling rates |

| Economic Impact | Supports mining communities and jobs | Supports circular economy and sustainable industry |

Overview of Tin Mining and Recycling

Tin mining primarily involves extracting cassiterite ore from alluvial or hard rock deposits, with major producers including China, Indonesia, and Peru. Tin recycling recovers tin from used products such as solder, tinplate, and electronics, significantly reducing environmental impact and conserving natural resources. Recycling processes contribute about 30-35% of the global tin supply, highlighting its growing importance alongside traditional mining methods.

Environmental Impact: Mining vs Recycling

Tin mining leads to significant environmental degradation, including habitat destruction, soil erosion, and water pollution from toxic chemicals such as cyanide and mercury. In contrast, tin recycling drastically reduces environmental impact by minimizing energy consumption, lowering greenhouse gas emissions by up to 90%, and conserving natural resources. The recycling process also curtails the release of harmful substances, promoting sustainable tin use in electronics and packaging industries.

Energy Consumption in Tin Extraction Methods

Tin mining consumes significantly more energy compared to tin recycling due to the intensive processes of ore extraction, crushing, and smelting. Recycling tin from scrap requires substantially less electricity and produces fewer greenhouse gas emissions, making it a more sustainable option. Energy savings in tin recycling can reach up to 90% compared to primary tin production from mined ore.

Economic Benefits of Tin Recycling

Tin recycling significantly reduces the demand for newly mined tin, lowering extraction costs and conserving natural resources. Recycled tin requires less energy to process, resulting in decreased production expenses and reduced environmental impact. Economic benefits include cost savings for manufacturers and increased profitability through efficient material reuse and waste minimization.

Resource Sustainability: Recycling vs Depleting Mines

Recycling tin significantly reduces reliance on finite tin ore reserves, promoting resource sustainability by lowering the environmental impact of mining activities. Tin mining depletes natural reserves and can cause habitat destruction, soil erosion, and water contamination, highlighting the importance of recycling to conserve materials. Efficient tin recycling processes recover up to 90% of tin from electronic waste, reducing the demand for newly mined ore and supporting a circular economy.

Technological Advances in Tin Recovery

Technological advances in tin recovery have significantly improved the efficiency of both tin mining and tin recycling processes. Innovations such as hydrometallurgical techniques and sensor-based ore sorting enhance the extraction rate of tin from low-grade ores, reducing environmental impact. Meanwhile, advanced recycling technologies like electrochemical separation and mechanical separation streamline the recovery of tin from electronic waste, boosting resource sustainability and supply chain resilience.

Social Implications of Tin Mining Operations

Tin mining operations often lead to significant social challenges including displacement of local communities, poor labor conditions, and health risks from exposure to toxic substances. In contrast, tin recycling minimizes environmental disruption and reduces the social burden by promoting sustainable resource use and safer working environments. Emphasizing recycling can enhance community well-being, decrease economic inequalities, and foster responsible stewardship of tin resources.

Regulatory Framework for Tin Production

Regulatory frameworks for tin production prioritize sustainable practices by enforcing strict environmental standards in both mining and recycling operations. Tin mining faces stringent regulations regarding land restoration, waste management, and water quality to mitigate ecological damage, while tin recycling is governed by policies promoting material recovery and reducing hazardous byproducts. Compliance with international agreements such as the Minamata Convention further drives the adoption of cleaner technologies and traceability in the entire tin supply chain.

Quality and Purity: Recycled Tin vs Mined Tin

Recycled tin typically maintains a high level of purity, often reaching 99.85% or higher due to advanced refining processes that remove impurities effectively. Mined tin, while initially pure, can contain trace elements and contaminants that require extensive smelting and refining to achieve comparable quality. The consistency of recycled tin quality provides manufacturers with a reliable source of material that meets strict industry standards without the environmental impact of mining.

Future Trends in Tin Supply Chain Management

Advancements in tin recycling technologies are expected to significantly enhance resource efficiency, reducing dependence on environmentally impactful mining operations. Integration of blockchain for traceability and AI-driven analytics will optimize supply chain transparency and forecasting, ensuring a more sustainable and resilient tin supply. Circular economy models promoting reuse and recovery of tin will drive future trends, mitigating raw material shortages and supporting green manufacturing initiatives.

Tin mining vs Tin recycling Infographic

materialdif.com

materialdif.com