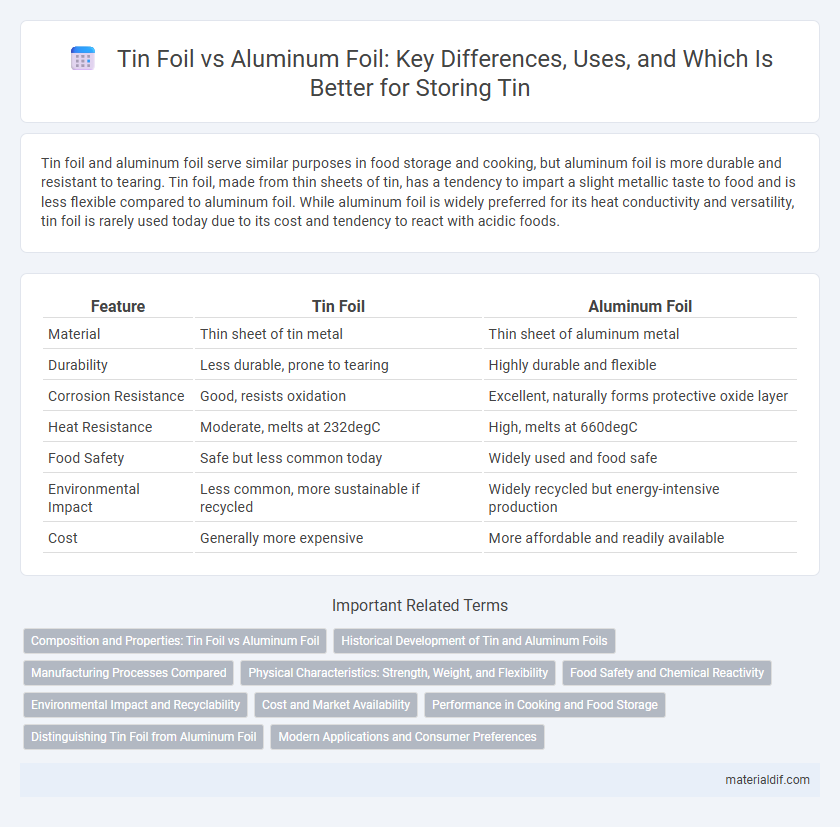

Tin foil and aluminum foil serve similar purposes in food storage and cooking, but aluminum foil is more durable and resistant to tearing. Tin foil, made from thin sheets of tin, has a tendency to impart a slight metallic taste to food and is less flexible compared to aluminum foil. While aluminum foil is widely preferred for its heat conductivity and versatility, tin foil is rarely used today due to its cost and tendency to react with acidic foods.

Table of Comparison

| Feature | Tin Foil | Aluminum Foil |

|---|---|---|

| Material | Thin sheet of tin metal | Thin sheet of aluminum metal |

| Durability | Less durable, prone to tearing | Highly durable and flexible |

| Corrosion Resistance | Good, resists oxidation | Excellent, naturally forms protective oxide layer |

| Heat Resistance | Moderate, melts at 232degC | High, melts at 660degC |

| Food Safety | Safe but less common today | Widely used and food safe |

| Environmental Impact | Less common, more sustainable if recycled | Widely recycled but energy-intensive production |

| Cost | Generally more expensive | More affordable and readily available |

Composition and Properties: Tin Foil vs Aluminum Foil

Tin foil consists of thin sheets of tin metal, known for its malleability and resistance to corrosion, while aluminum foil is made from aluminum, valued for its lightweight and high tensile strength. Tin foil has a higher melting point of around 232degC compared to aluminum's lower melting point of 660degC, influencing their heat resistance and cooking applications. Aluminum foil offers superior flexibility and better impermeability to moisture and gases, making it more widely used in food packaging and preservation.

Historical Development of Tin and Aluminum Foils

Tin foil, first used in the late 19th century, was widely adopted for food wrapping due to its malleability and resistance to moisture. Aluminum foil, developed in the early 20th century, rapidly replaced tin foil because of aluminum's abundance, superior strength, and lower cost of production. By the mid-20th century, advances in aluminum manufacturing solidified aluminum foil as the dominant material for packaging and insulation applications.

Manufacturing Processes Compared

Tin foil is produced by rolling pure tin into thin sheets, a process that requires more labor and time due to tin's malleability and cost, resulting in a thicker and less flexible foil. Aluminum foil manufacturing involves rolling aluminum alloy into ultra-thin sheets through continuous cold rolling, enabling higher precision and efficiency at lower cost. The differing manufacturing processes affect each foil's durability, thermal conductivity, and environmental impact, with aluminum foil being more widely used in modern applications due to these manufacturing advantages.

Physical Characteristics: Strength, Weight, and Flexibility

Tin foil exhibits lower tensile strength compared to aluminum foil, making it more prone to tearing under stress. Aluminum foil is lighter and offers greater flexibility, allowing it to conform tightly to objects without breaking. The enhanced durability and pliability of aluminum foil make it superior for wrapping and preserving food items.

Food Safety and Chemical Reactivity

Tin foil, historically used for food wrapping, is less reactive and safer for acidic foods compared to aluminum foil, which can leach aluminum ions under high heat or acidic conditions. Aluminum foil's chemical reactivity may introduce trace amounts of aluminum into food, raising concerns for health-conscious consumers. In contrast, tin foil offers more inert properties, reducing the risk of food contamination and making it preferable for long-term food storage.

Environmental Impact and Recyclability

Tin foil, made from thin layers of tin, is biodegradable and less harmful to the environment compared to aluminum foil, which requires energy-intensive mining and refining processes. Aluminum foil is widely recyclable but often contaminated by food residues, reducing recycling efficiency and contributing to landfill waste. Choosing tin foil can reduce ecological impact due to its eco-friendly decomposition, while proper cleaning enhances aluminum foil's recyclability.

Cost and Market Availability

Tin foil is generally more expensive than aluminum foil due to the higher cost of tin metal extraction and processing. Aluminum foil dominates the market with widespread availability and lower cost, making it the preferred choice for most industrial and household applications. Limited production of tin foil leads to scarcity in the market, further driving up its price compared to the abundant supply of aluminum foil.

Performance in Cooking and Food Storage

Tin foil offers excellent heat retention and a non-reactive surface ideal for cooking acidic foods, preventing metallic taste transfer. Aluminum foil provides superior durability and higher heat tolerance, making it suitable for grilling and roasting at elevated temperatures. For food storage, tin foil effectively preserves flavor without leaching, but aluminum foil's flexibility and sealability ensure better airtight protection and longer freshness.

Distinguishing Tin Foil from Aluminum Foil

Tin foil and aluminum foil differ primarily in composition, with tin foil made from pure tin and aluminum foil from aluminum alloy. Tin foil is thicker, more prone to breakage, and imparts a slight metallic taste to food, while aluminum foil is thin, flexible, and widely used for cooking and packaging due to its durability. Unlike aluminum foil, tin foil is less resistant to oxidation and has largely been replaced by aluminum foil in most household and industrial applications.

Modern Applications and Consumer Preferences

Tin foil, once widely used for food packaging, has largely been replaced by aluminum foil due to aluminum's superior strength, flexibility, and cost-effectiveness. Modern applications favor aluminum foil for its excellent barrier properties against moisture, light, and bacteria, making it ideal for food preservation and cooking. Consumer preferences align with aluminum foil because it is more readily available, recyclable, and compatible with various packaging technologies.

Tin foil vs Aluminum foil Infographic

materialdif.com

materialdif.com