Hot-dipped tin offers superior corrosion resistance and thicker coating layers, making it ideal for harsh environments where durability is critical. Electroplated tin provides a smoother, more uniform finish with better electrical conductivity, suitable for precision electronic components. Choosing between hot-dipped and electroplated tin depends on specific application requirements such as environmental exposure and performance needs.

Table of Comparison

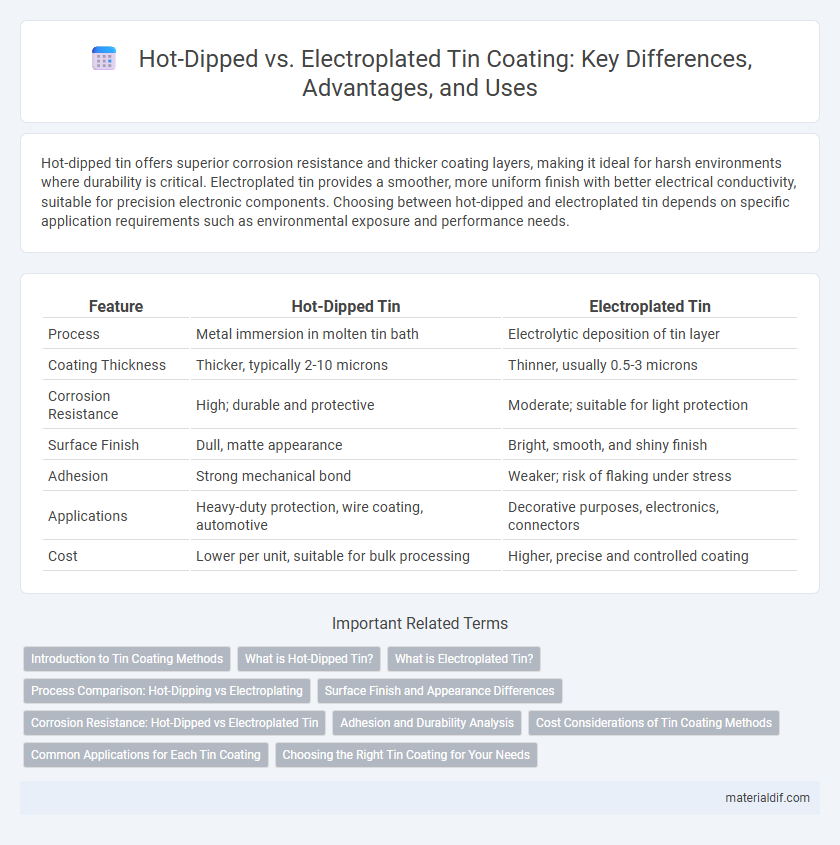

| Feature | Hot-Dipped Tin | Electroplated Tin |

|---|---|---|

| Process | Metal immersion in molten tin bath | Electrolytic deposition of tin layer |

| Coating Thickness | Thicker, typically 2-10 microns | Thinner, usually 0.5-3 microns |

| Corrosion Resistance | High; durable and protective | Moderate; suitable for light protection |

| Surface Finish | Dull, matte appearance | Bright, smooth, and shiny finish |

| Adhesion | Strong mechanical bond | Weaker; risk of flaking under stress |

| Applications | Heavy-duty protection, wire coating, automotive | Decorative purposes, electronics, connectors |

| Cost | Lower per unit, suitable for bulk processing | Higher, precise and controlled coating |

Introduction to Tin Coating Methods

Hot-dipped tin coating involves immersing the substrate into molten tin, creating a thick, durable layer that offers excellent corrosion resistance and solderability. Electroplated tin coating uses an electrolytic process to deposit a thin, uniform layer of tin, providing enhanced surface smoothness and precise thickness control for sensitive electronic components. Both methods improve the metal's performance and longevity but differ significantly in application techniques, coating thickness, and typical use cases across industries.

What is Hot-Dipped Tin?

Hot-dipped tin is a protective coating process where steel or other metals are submerged in molten tin, creating a thick, durable layer that enhances corrosion resistance. This method provides superior adhesion and a more uniform coating compared to electroplated tin, which relies on an electrically-applied thin tin layer. The hot-dipped tin coating is especially valuable in industrial applications requiring long-lasting protection in harsh environments.

What is Electroplated Tin?

Electroplated tin is a thin layer of pure tin deposited onto a metal surface using an electrochemical process, enhancing corrosion resistance and solderability. This method ensures a uniform coating thickness, improving the metal's durability and conductivity in electronic components. Electroplated tin is commonly used in circuit boards and connectors due to its excellent adhesion and ability to prevent oxidation.

Process Comparison: Hot-Dipping vs Electroplating

Hot-dipped tin coating involves immersing the substrate into molten tin at approximately 250degC, creating a thick, durable layer that offers superior corrosion resistance and excellent adhesion. Electroplated tin uses an electrolytic bath to deposit a thinner, more uniform tin layer at ambient temperatures, allowing precise control over coating thickness and surface finish. While hot-dipping provides enhanced protection for heavy-duty applications, electroplating is favored for fine, intricate components requiring detailed surface coverage.

Surface Finish and Appearance Differences

Hot-dipped tin coating offers a thicker, more robust surface finish characterized by a matte or slightly rough texture, providing enhanced corrosion resistance and durability. Electroplated tin results in a thinner, smoother, and shinier surface finish with a bright, reflective appearance, often preferred for decorative purposes and fine electronic components. The thicker hot-dipped layer exhibits better wear and abrasion resistance, while electroplated tin provides superior aesthetics and finer control over coating thickness.

Corrosion Resistance: Hot-Dipped vs Electroplated Tin

Hot-dipped tin coating provides superior corrosion resistance compared to electroplated tin due to its thicker and more uniform layer that withstands harsh environmental conditions. Electroplated tin coatings are thinner and more susceptible to wear and corrosion, especially in humid or acidic environments. For applications requiring long-term durability and protection against oxidation, hot-dipped tin is the preferred choice.

Adhesion and Durability Analysis

Hot-dipped tin coatings exhibit superior adhesion due to the metallurgical bond formed between the molten tin and the substrate, resulting in enhanced mechanical interlocking and resistance to peeling. Electroplated tin layers, while offering smooth and uniform finishes, often rely on mechanical adhesion that may be less durable under thermal cycling and mechanical stress. Durability tests reveal that hot-dipped tin outperforms electroplated tin in corrosion resistance and wear, making it ideal for heavy-duty applications requiring long-term reliability.

Cost Considerations of Tin Coating Methods

Hot-dipped tin coating generally incurs higher initial costs than electroplated tin due to the extensive use of molten tin baths and energy requirements. Electroplated tin is more cost-effective for precision applications and thin coatings, minimizing material waste and enabling faster production cycles. Cost efficiency depends on the specific application, with hot-dipped tin favored for heavy-duty corrosion resistance and electroplated tin preferred for decorative or electronic component finishes.

Common Applications for Each Tin Coating

Hot-dipped tin coatings are commonly used in applications requiring robust corrosion resistance and thicker protective layers, such as in automotive parts, electrical connectors, and food packaging. Electroplated tin is favored for electronic components, printed circuit boards (PCBs), and fine metal parts due to its smooth finish and precise thickness control. Both methods enhance solderability and protect against oxidation, but choice depends on specific industry standards and environmental exposure.

Choosing the Right Tin Coating for Your Needs

Hot-dipped tin coatings provide superior corrosion resistance and thicker coverage, making them ideal for heavy-duty industrial applications exposed to harsh environments. Electroplated tin offers a smoother, more uniform finish with precise control over layer thickness, suitable for electronic components requiring fine detail and electrical conductivity. Selecting the right tin coating depends on balancing durability requirements, surface finish quality, and cost considerations specific to your project's demands.

Hot-dipped vs Electroplated Tin Infographic

materialdif.com

materialdif.com