Tin-coated copper wire offers enhanced corrosion resistance compared to bare copper wire, making it ideal for environments exposed to moisture or chemicals. The tin coating improves solderability and extends the wire's lifespan in electrical applications. Bare copper wire, while highly conductive and cost-effective, is more susceptible to oxidation and may require additional protective measures in harsh conditions.

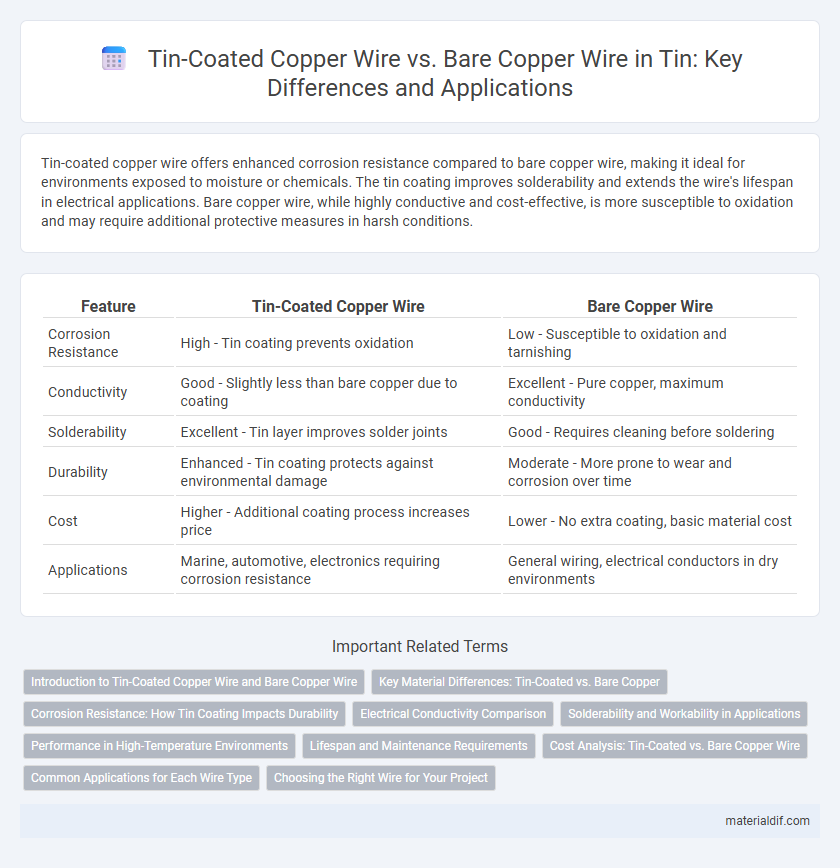

Table of Comparison

| Feature | Tin-Coated Copper Wire | Bare Copper Wire |

|---|---|---|

| Corrosion Resistance | High - Tin coating prevents oxidation | Low - Susceptible to oxidation and tarnishing |

| Conductivity | Good - Slightly less than bare copper due to coating | Excellent - Pure copper, maximum conductivity |

| Solderability | Excellent - Tin layer improves solder joints | Good - Requires cleaning before soldering |

| Durability | Enhanced - Tin coating protects against environmental damage | Moderate - More prone to wear and corrosion over time |

| Cost | Higher - Additional coating process increases price | Lower - No extra coating, basic material cost |

| Applications | Marine, automotive, electronics requiring corrosion resistance | General wiring, electrical conductors in dry environments |

Introduction to Tin-Coated Copper Wire and Bare Copper Wire

Tin-coated copper wire features a thin layer of tin plating that enhances corrosion resistance and solderability, making it ideal for electronic applications. Bare copper wire, composed solely of pure copper, offers superior electrical conductivity but is prone to oxidation and corrosion over time. Choosing between the two depends on factors like environmental exposure, conductivity requirements, and long-term durability.

Key Material Differences: Tin-Coated vs. Bare Copper

Tin-coated copper wire features a thin layer of tin plating over the copper core, enhancing corrosion resistance and solderability compared to bare copper wire, which consists solely of pure copper. The tin coating prevents oxidation, extending the wire's lifespan in harsh environments such as marine and industrial applications, while bare copper offers superior electrical conductivity and lower resistance in controlled settings. Material selection depends on balancing the need for durability and protection against environmental factors with optimal electrical performance requirements.

Corrosion Resistance: How Tin Coating Impacts Durability

Tin-coated copper wire exhibits significantly enhanced corrosion resistance compared to bare copper wire, as the tin layer acts as a protective barrier against moisture and oxidation. This coating prevents the copper from reacting with environmental elements, reducing the risk of rust, tarnish, and electrical conductivity loss over time. The enhanced durability of tin-coated copper wire makes it ideal for applications in harsh or humid environments where bare copper would degrade more rapidly.

Electrical Conductivity Comparison

Tin-coated copper wire exhibits slightly lower electrical conductivity compared to bare copper wire due to the thin tin layer's higher resistivity. Bare copper wire typically offers superior conductivity, around 58 MS/m, while tin-coated copper wire registers marginally less, approximately 55-57 MS/m. The tin coating enhances corrosion resistance but introduces a minor trade-off in electrical performance.

Solderability and Workability in Applications

Tin-coated copper wire offers superior solderability compared to bare copper wire due to the tin layer promoting better wetting and faster solder flow, essential for reliable electrical connections. The tin coating also provides enhanced corrosion resistance, which improves workability by preventing oxidation during handling and assembly processes. In applications requiring repeated bending or soldering, tin-coated copper wire maintains conductivity and surface integrity longer than bare copper wire, making it ideal for electronics and automotive wiring.

Performance in High-Temperature Environments

Tin-coated copper wire offers superior corrosion resistance and maintains conductivity better than bare copper wire in high-temperature environments, reducing oxidation and prolonging wire lifespan. The tin coating acts as a protective barrier against thermal degradation, making it ideal for applications exposed to elevated temperatures. Bare copper wire, while highly conductive, is more susceptible to oxidization and performance decline under sustained heat.

Lifespan and Maintenance Requirements

Tin-coated copper wire offers enhanced corrosion resistance compared to bare copper wire, significantly extending its lifespan especially in humid or corrosive environments. The tin coating acts as a protective barrier, reducing oxidation and minimizing maintenance needs such as cleaning or replacement. Bare copper wire, while conductive, requires more frequent inspection and upkeep due to its susceptibility to tarnishing and degradation over time.

Cost Analysis: Tin-Coated vs. Bare Copper Wire

Tin-coated copper wire typically incurs higher initial costs due to the additional plating process, but offers longer service life by resisting corrosion and reducing maintenance expenses. Bare copper wire has lower upfront costs but is more susceptible to oxidation, potentially leading to increased replacement and failure-related costs over time. Evaluating total cost of ownership reveals tin-coated wire as a more cost-effective solution in environments prone to moisture or chemical exposure.

Common Applications for Each Wire Type

Tin-coated copper wire is widely used in marine, automotive, and electronics applications where corrosion resistance and solderability are critical, such as grounding wires, circuit boards, and connectors. Bare copper wire is commonly employed in electrical wiring, power distribution, and telecommunications due to its excellent conductivity and cost-effectiveness for general-purpose use. Both wire types serve essential roles, with tin coating providing enhanced durability in harsh environments while bare copper offers superior electrical performance in standard conditions.

Choosing the Right Wire for Your Project

Tin-coated copper wire offers superior corrosion resistance and improved solderability compared to bare copper wire, making it ideal for applications in humid or harsh environments. Bare copper wire provides excellent electrical conductivity and lower cost, suitable for standard electrical projects without exposure to corrosive elements. Selecting the right wire depends on environmental conditions, budget constraints, and the specific performance needs of your project.

Tin-coated copper wire vs Bare copper wire Infographic

materialdif.com

materialdif.com