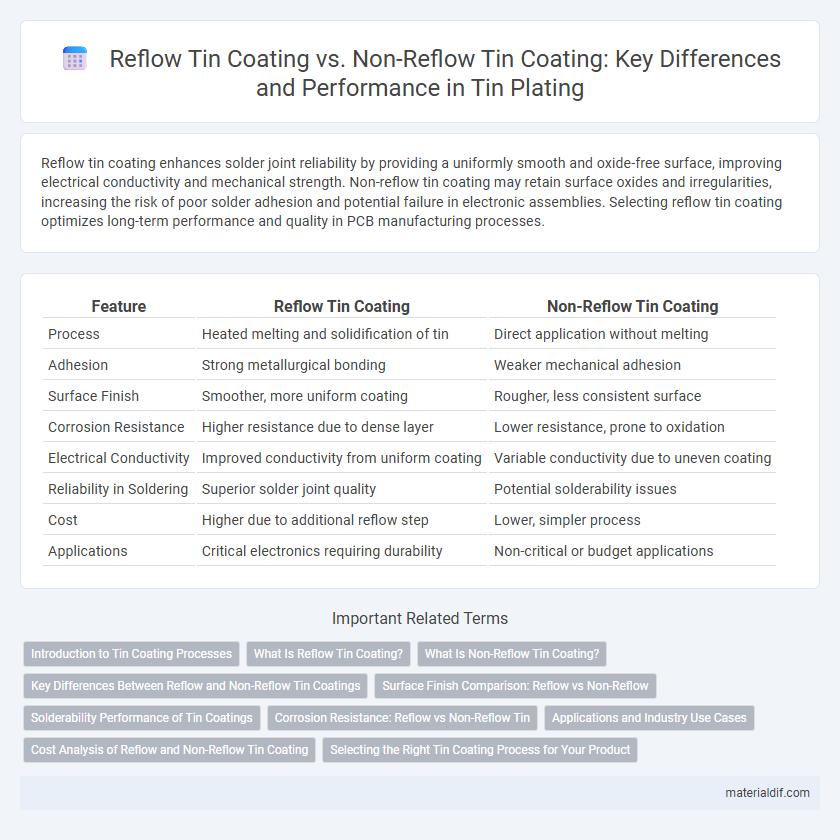

Reflow tin coating enhances solder joint reliability by providing a uniformly smooth and oxide-free surface, improving electrical conductivity and mechanical strength. Non-reflow tin coating may retain surface oxides and irregularities, increasing the risk of poor solder adhesion and potential failure in electronic assemblies. Selecting reflow tin coating optimizes long-term performance and quality in PCB manufacturing processes.

Table of Comparison

| Feature | Reflow Tin Coating | Non-Reflow Tin Coating |

|---|---|---|

| Process | Heated melting and solidification of tin | Direct application without melting |

| Adhesion | Strong metallurgical bonding | Weaker mechanical adhesion |

| Surface Finish | Smoother, more uniform coating | Rougher, less consistent surface |

| Corrosion Resistance | Higher resistance due to dense layer | Lower resistance, prone to oxidation |

| Electrical Conductivity | Improved conductivity from uniform coating | Variable conductivity due to uneven coating |

| Reliability in Soldering | Superior solder joint quality | Potential solderability issues |

| Cost | Higher due to additional reflow step | Lower, simpler process |

| Applications | Critical electronics requiring durability | Non-critical or budget applications |

Introduction to Tin Coating Processes

Reflow tin coating involves a controlled heating process that melts the tin, promoting superior adhesion and a smoother, more uniform surface on electronic components. In contrast, non-reflow tin coating applies tin at room temperature or without melting, often resulting in a rougher finish with potentially weaker bonding. Understanding the differences in these tin coating processes is essential for optimizing solderability and corrosion resistance in PCB manufacturing.

What Is Reflow Tin Coating?

Reflow tin coating is a surface finishing process where tin is melted and solidified on a substrate to create a smooth, uniform layer that enhances solderability and corrosion resistance. This method involves heating the tin-coated component to reflow the tin, ensuring improved adhesion and eliminating surface defects such as dross or oxidation. The resulting coating provides superior mechanical strength and electrical conductivity compared to non-reflow tin coatings, making it ideal for electronic components and PCB applications.

What Is Non-Reflow Tin Coating?

Non-reflow tin coating refers to a type of surface finish applied to electronic components that does not undergo the reflow soldering process. This coating provides a protective layer against oxidation and enhances solderability without melting or redistributing during assembly. It is commonly used in applications where precise solder joint geometry and minimal thermal exposure are critical.

Key Differences Between Reflow and Non-Reflow Tin Coatings

Reflow tin coating involves melting the tin to create a smooth, uniform layer that enhances solderability and reduces surface oxidation, while non-reflow tin coating applies tin without melting, resulting in a rougher, less uniform surface prone to increased oxidation. Key differences include surface finish quality, adhesion strength, and solder joint reliability, with reflow coatings providing superior wetting and mechanical bonding. Reflow tin coatings also improve electrical conductivity and reduce void formation in solder joints compared to non-reflow coatings.

Surface Finish Comparison: Reflow vs Non-Reflow

Reflow tin coating provides a smoother and more uniform surface finish compared to non-reflow tin coating, resulting in improved solderability and reduced risk of surface defects such as tin whiskers. The reflow process enables better wetting and stronger metallurgical bonding, enhancing joint reliability in electronic assemblies. Non-reflow tin coatings often exhibit uneven thickness and rougher textures, which can lead to inconsistent solder joints and potential long-term failure in circuit boards.

Solderability Performance of Tin Coatings

Reflow tin coating significantly enhances solderability performance by creating a uniform, smooth surface that improves wetting and reduces solder bridging during assembly. Non-reflow tin coatings often result in higher surface roughness and oxide formation, which can impair solder joint quality and increase the risk of defects. Empirical studies show that reflow tin coatings consistently yield lower contact resistance and stronger metallurgical bonds compared to non-reflow counterparts.

Corrosion Resistance: Reflow vs Non-Reflow Tin

Reflow tin coating exhibits superior corrosion resistance compared to non-reflow tin due to its uniform and dense microstructure formed during the reflow soldering process. Non-reflow tin coatings tend to have porous and uneven surfaces that accelerate oxidation and corrosion in humid or harsh environments. Studies show that reflow tin substantially reduces surface oxidation, enhancing the longevity and reliability of electronic components in corrosive conditions.

Applications and Industry Use Cases

Reflow tin coating is predominantly used in electronics manufacturing, enhancing solderability and providing reliable electrical connections in printed circuit boards (PCBs) for consumer electronics and automotive industries. Non-reflow tin coating finds applications in corrosion resistance and surface protection of metal components in industrial machinery and household appliances. These coatings are critical in sectors like aerospace and telecommunications, where durability and performance under thermal stress are essential.

Cost Analysis of Reflow and Non-Reflow Tin Coating

Reflow tin coating typically incurs higher initial costs due to the additional heating process required to melt and solidify the tin, improving adhesion and surface finish. Non-reflow tin coating offers lower upfront expenses by applying tin directly without reheating, but it may lead to higher long-term costs related to reliability issues such as poor solderability or increased oxidation. Cost analysis must weigh the immediate savings of non-reflow methods against potential maintenance and failure expenses associated with inferior coating performance.

Selecting the Right Tin Coating Process for Your Product

Reflow tin coating provides superior solderability and enhanced mechanical strength by melting the tin layer to form a uniform, smooth surface, ideal for high-reliability electronic components. Non-reflow tin coating, applied at lower temperatures without melting, offers cost-effective protection against oxidation but may result in less consistent surface quality and solder joint reliability. Selecting the right tin coating process depends on product requirements for durability, solderability, and manufacturing cost constraints, with reflow coatings preferred for advanced electronics and non-reflow suitable for simpler, budget-sensitive applications.

Reflow Tin Coating vs Non-Reflow Tin Coating Infographic

materialdif.com

materialdif.com