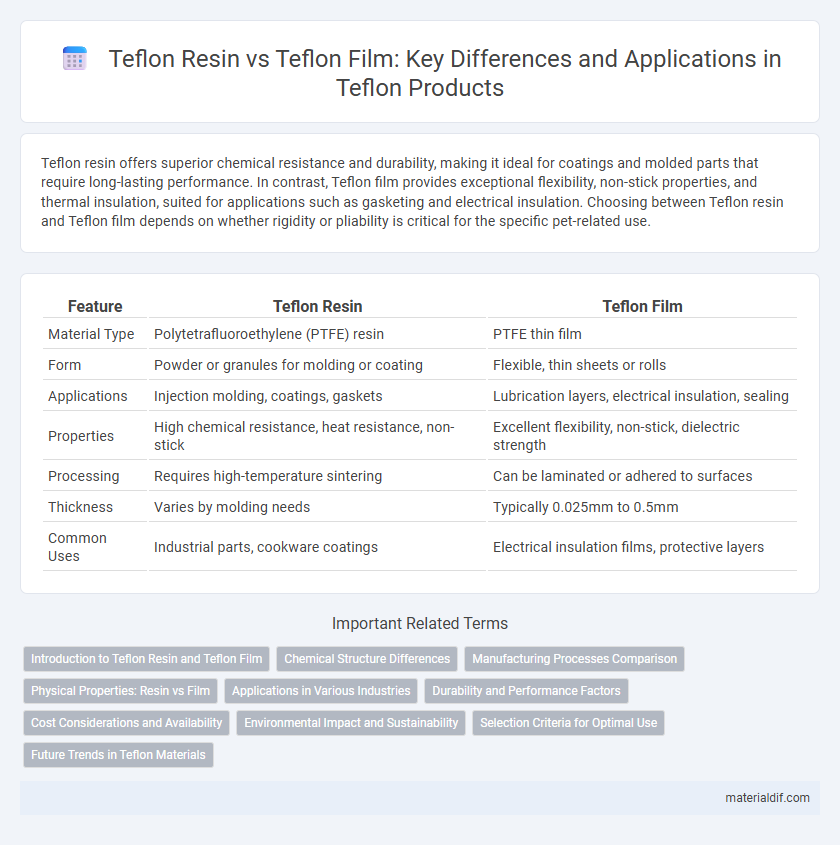

Teflon resin offers superior chemical resistance and durability, making it ideal for coatings and molded parts that require long-lasting performance. In contrast, Teflon film provides exceptional flexibility, non-stick properties, and thermal insulation, suited for applications such as gasketing and electrical insulation. Choosing between Teflon resin and Teflon film depends on whether rigidity or pliability is critical for the specific pet-related use.

Table of Comparison

| Feature | Teflon Resin | Teflon Film |

|---|---|---|

| Material Type | Polytetrafluoroethylene (PTFE) resin | PTFE thin film |

| Form | Powder or granules for molding or coating | Flexible, thin sheets or rolls |

| Applications | Injection molding, coatings, gaskets | Lubrication layers, electrical insulation, sealing |

| Properties | High chemical resistance, heat resistance, non-stick | Excellent flexibility, non-stick, dielectric strength |

| Processing | Requires high-temperature sintering | Can be laminated or adhered to surfaces |

| Thickness | Varies by molding needs | Typically 0.025mm to 0.5mm |

| Common Uses | Industrial parts, cookware coatings | Electrical insulation films, protective layers |

Introduction to Teflon Resin and Teflon Film

Teflon resin is a versatile fluoropolymer known for its chemical resistance and non-stick properties, widely used in coatings, molds, and sealants. Teflon film, derived from Teflon resin, provides a thin, flexible sheet with excellent thermal stability and low friction, ideal for insulation, gaskets, and protective linings. Both forms leverage polytetrafluoroethylene (PTFE) to deliver high-performance solutions across industrial and consumer applications.

Chemical Structure Differences

Teflon resin consists of polymerized tetrafluoroethylene forming a solid, moldable material with a dense, cross-linked chemical structure that provides high chemical resistance and thermal stability. In contrast, Teflon film is produced by stretching the resin into thin, flexible sheets, resulting in a highly oriented crystalline structure that enhances its mechanical strength and flexibility. These structural differences between resin and film influence their applications, with resin favoring molding and machining, while film suits coatings and protective layers.

Manufacturing Processes Comparison

Teflon resin is produced through a polymerization process involving the chemical vapor deposition of tetrafluoroethylene monomers, resulting in a granular or powder form used for molding and extrusion. In contrast, Teflon film is manufactured by calendaring or skiving techniques, where the resin is heated, stretched, and rolled into thin, continuous sheets with uniform thickness. The film production demands precise temperature and tension control to achieve the desired mechanical properties and surface finish essential for applications like electrical insulation and chemical-resistant liners.

Physical Properties: Resin vs Film

Teflon resin exhibits a dense, amorphous structure resulting in high chemical resistance and excellent thermal stability, typically rated up to 260degC. In contrast, Teflon film possesses a thin, flexible morphology with superior dielectric strength and low friction, making it ideal for electrical insulation and non-stick coatings. The physical density of Teflon resin is generally higher (around 2.2 g/cm3) compared to the film, which enhances its mechanical robustness but reduces flexibility.

Applications in Various Industries

Teflon resin, known for its superior chemical resistance and high melting point, is widely used in industrial coatings, automotive parts, and chemical processing equipment to enhance durability under harsh conditions. Teflon film offers exceptional non-stick properties and is utilized in electronics for insulation, as well as in food packaging and medical devices where flexibility and low friction are critical. Both forms serve distinct roles across aerospace, electronics, and food industries, leveraging Teflon's unique chemical inertness and thermal stability.

Durability and Performance Factors

Teflon resin offers superior chemical resistance and high-temperature stability, making it ideal for applications requiring long-term durability in harsh environments. Teflon film provides excellent flexibility and low friction properties, enhancing performance in dynamic sealing and electrical insulation tasks. Performance factors such as tensile strength and elongation differ, with resin excelling in structural applications, while film is preferred for lightweight, flexible uses.

Cost Considerations and Availability

Teflon resin generally costs less than Teflon film due to its bulk form, making it more accessible for large-scale manufacturing processes. Teflon film, being a finished product with uniform thickness and enhanced surface properties, commands a higher price and has more limited availability. Manufacturers often weigh the cost-effectiveness of resin for molding applications against the premium price and specialized uses of Teflon film in high-performance sealing and insulation.

Environmental Impact and Sustainability

Teflon resin, commonly used in coatings and industrial applications, poses environmental challenges due to the production processes involving perfluorinated compounds that persist in ecosystems and resist degradation. Teflon film, often utilized in non-stick cookware and electrical insulation, presents sustainability concerns primarily related to disposal and recycling difficulties, as the fluoropolymer structure is not readily biodegradable. Innovations in manufacturing aim to reduce greenhouse gas emissions and develop more sustainable fluoropolymer alternatives, but both forms demand careful management to mitigate long-term environmental impact.

Selection Criteria for Optimal Use

Teflon resin offers superior chemical resistance and high-temperature stability, making it ideal for applications requiring strong bonding or intricate molding. Teflon film provides exceptional non-stick properties, flexibility, and electrical insulation, suitable for coatings, gaskets, and insulating layers. Selection criteria should consider factors such as mechanical strength, thermal endurance, electrical insulation requirements, and the nature of chemical exposure to determine the optimal form of Teflon.

Future Trends in Teflon Materials

Teflon resin exhibits promising advancements in enhanced chemical resistance and thermal stability, driving innovation in automotive and aerospace coatings. Teflon film continues evolving with thinner, more flexible variants enabling new applications in electronics, medical devices, and flexible insulation. Future trends emphasize nanocomposite integration and eco-friendly production processes to meet rising demands for sustainable and high-performance fluoropolymer materials.

Teflon Resin vs Teflon Film Infographic

materialdif.com

materialdif.com