Etched Teflon offers improved adhesion properties compared to non-etched Teflon, making it ideal for applications requiring strong bonding with paints or coatings. The etching process creates microscopic texture on the Teflon surface, enhancing mechanical grip and surface energy. Non-etched Teflon retains its smooth, non-stick characteristics but lacks the surface roughness needed for effective adhesion.

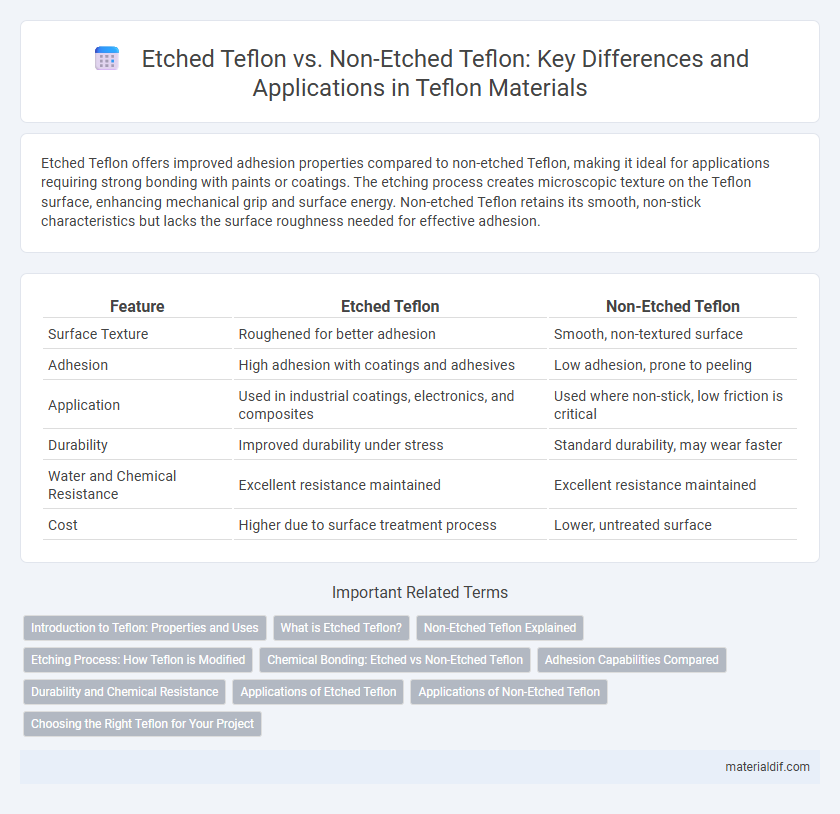

Table of Comparison

| Feature | Etched Teflon | Non-Etched Teflon |

|---|---|---|

| Surface Texture | Roughened for better adhesion | Smooth, non-textured surface |

| Adhesion | High adhesion with coatings and adhesives | Low adhesion, prone to peeling |

| Application | Used in industrial coatings, electronics, and composites | Used where non-stick, low friction is critical |

| Durability | Improved durability under stress | Standard durability, may wear faster |

| Water and Chemical Resistance | Excellent resistance maintained | Excellent resistance maintained |

| Cost | Higher due to surface treatment process | Lower, untreated surface |

Introduction to Teflon: Properties and Uses

Etched Teflon exhibits enhanced surface roughness that improves adhesion properties, making it ideal for applications requiring strong bonding with paints, adhesives, or coatings. Non-etched Teflon maintains its smooth, non-stick, and chemical-resistant surface, commonly used in cookware, electrical insulation, and industrial sealants. Understanding these differences is crucial for selecting the right Teflon type based on performance requirements in various industrial and consumer applications.

What is Etched Teflon?

Etched Teflon refers to Teflon that has undergone a surface treatment process to create microscopic roughness, enhancing its adhesion properties. This treatment improves bonding with inks, coatings, or adhesives, which is typically poor on standard, non-etched Teflon due to its low surface energy. Etched Teflon is widely used in applications requiring reliable surface adhesion without compromising the inherent non-stick and chemical-resistant characteristics of Teflon.

Non-Etched Teflon Explained

Non-etched Teflon, known for its smooth and non-porous surface, maintains exceptional chemical resistance and low friction properties without surface modification. Unlike etched Teflon, it lacks surface roughness, resulting in reduced adhesion capabilities but enhanced non-stick performance critical for coatings in cookware and industrial applications. This inert nature makes non-etched Teflon ideal where contamination prevention and ease of cleaning are paramount.

Etching Process: How Teflon is Modified

The etching process modifies Teflon by creating microscopic roughness and increasing surface energy, which significantly improves adhesion properties for coatings and adhesives. This is typically achieved through chemical etching using sodium or potassium solutions, selectively altering the chemically inert polytetrafluoroethylene (PTFE) surface without compromising its structural integrity. Compared to non-etched Teflon, etched Teflon exhibits enhanced wettability and stronger bonding capabilities, essential for industrial applications requiring durable and reliable surface modifications.

Chemical Bonding: Etched vs Non-Etched Teflon

Etched Teflon surfaces exhibit enhanced chemical bonding due to increased surface roughness and higher surface energy, allowing better adhesion with coatings and adhesives. Non-etched Teflon maintains its smooth, low-energy surface, resulting in poor chemical bonding and weak adhesion properties. The etching process disrupts Teflon's inert fluoropolymer structure, facilitating stronger molecular interactions compared to pristine Teflon.

Adhesion Capabilities Compared

Etched Teflon surfaces exhibit significantly enhanced adhesion capabilities due to increased surface roughness and polarity, allowing coatings and adhesives to bond more effectively compared to smooth, non-etched Teflon. Non-etched Teflon's low surface energy and chemical inertness result in poor adhesive strength, often requiring surface treatment to improve bonding. The etching process introduces micro-porosity and modifies surface chemistry, which promotes mechanical interlocking and chemical interactions critical for improved adhesion performance in industrial applications.

Durability and Chemical Resistance

Etched Teflon features a surface treatment that improves paint adhesion and mechanical bonding without compromising its inherent chemical resistance, making it more durable in applications requiring strong coatings. Non-etched Teflon maintains superior chemical inertness and resistance to solvents, acids, and bases but may suffer from weaker coating adhesion, potentially reducing durability under mechanical stresses. Both variants offer excellent resistance to corrosion and harsh chemicals, but etched Teflon is preferred for enhanced durability in environments where surface coatings are essential.

Applications of Etched Teflon

Etched Teflon offers superior adhesion properties compared to non-etched Teflon, making it ideal for applications requiring strong bonding with paints, adhesives, and coatings in automotive and aerospace industries. Its enhanced surface roughness allows for improved electrical insulation in printed circuit boards and flexible electronics. Etched Teflon is also widely used in medical devices where durable, non-slip coatings are essential for reliability and safety.

Applications of Non-Etched Teflon

Non-etched Teflon is widely used in applications requiring superior chemical resistance and non-stick properties, such as cookware linings and chemical processing equipment. Its smooth, non-porous surface prevents material adhesion, making it ideal for fluid handling and gasket manufacturing. The material's inertness and low friction coefficient contribute to its robustness in both industrial and consumer product applications.

Choosing the Right Teflon for Your Project

Etched Teflon features a surface treatment that enhances adhesion, making it ideal for projects requiring strong bonding with adhesives, coatings, or other materials. Non-etched Teflon retains its naturally non-stick, low-friction properties, suitable for applications where chemical resistance and minimal surface interaction are priorities. Selecting the right Teflon depends on whether your project demands improved adhesion or maximum chemical inertness and non-stick characteristics.

Etched Teflon vs Non-Etched Teflon Infographic

materialdif.com

materialdif.com