Teflon tubing offers superior chemical resistance and temperature tolerance compared to PVC tubing, making it ideal for demanding industrial applications. Its non-stick surface resists buildup and contamination, ensuring cleaner fluid transfer in sensitive processes. PVC tubing, while more cost-effective and flexible, lacks the durability and high-temperature stability that Teflon provides.

Table of Comparison

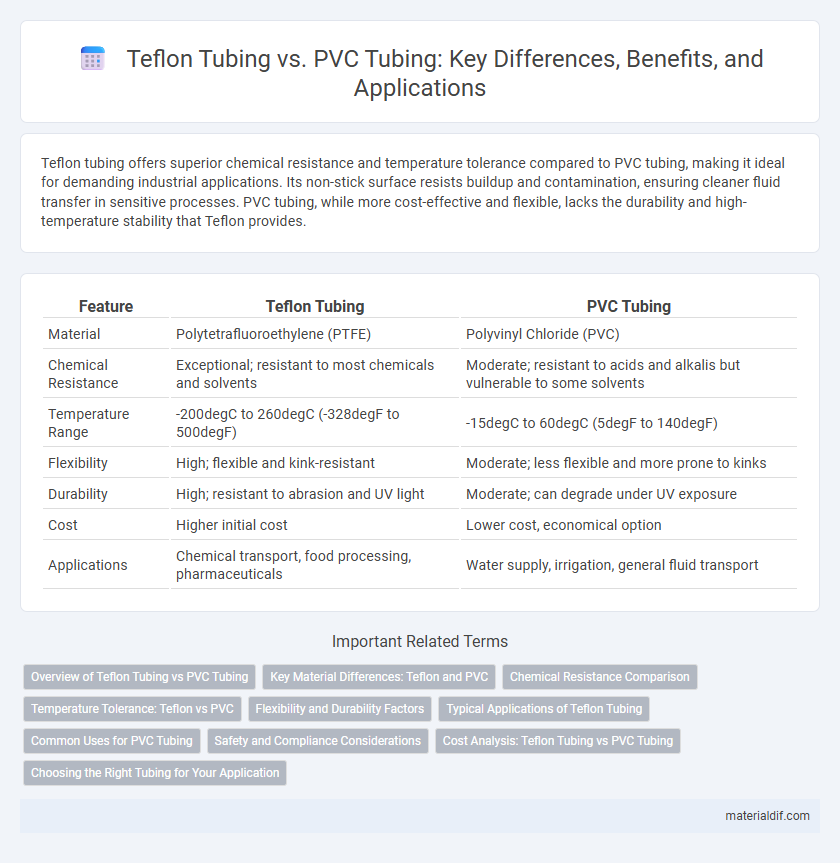

| Feature | Teflon Tubing | PVC Tubing |

|---|---|---|

| Material | Polytetrafluoroethylene (PTFE) | Polyvinyl Chloride (PVC) |

| Chemical Resistance | Exceptional; resistant to most chemicals and solvents | Moderate; resistant to acids and alkalis but vulnerable to some solvents |

| Temperature Range | -200degC to 260degC (-328degF to 500degF) | -15degC to 60degC (5degF to 140degF) |

| Flexibility | High; flexible and kink-resistant | Moderate; less flexible and more prone to kinks |

| Durability | High; resistant to abrasion and UV light | Moderate; can degrade under UV exposure |

| Cost | Higher initial cost | Lower cost, economical option |

| Applications | Chemical transport, food processing, pharmaceuticals | Water supply, irrigation, general fluid transport |

Overview of Teflon Tubing vs PVC Tubing

Teflon tubing, made from polytetrafluoroethylene (PTFE), offers superior chemical resistance, high-temperature tolerance up to 260degC, and excellent non-stick properties compared to PVC tubing, which is more cost-effective but less durable under extreme conditions. PVC tubing typically handles temperatures up to 60degC and may degrade when exposed to harsh chemicals, whereas Teflon tubing is ideal for applications requiring purity and resistance to corrosive fluids. Teflon's flexibility, low friction, and inertness make it preferable in pharmaceutical, chemical processing, and food industries, while PVC tubing is commonly used for general water, air, and low-pressure fluid transport.

Key Material Differences: Teflon and PVC

Teflon tubing is made from polytetrafluoroethylene (PTFE), offering superior chemical resistance, high-temperature tolerance up to 260degC, and low friction properties. PVC tubing, composed of polyvinyl chloride, is more rigid, less heat resistant with a maximum temperature around 60degC, and susceptible to chemical degradation from solvents and oils. These material differences make Teflon tubing ideal for demanding applications in chemical processing and laboratory environments, while PVC tubing suits general-purpose fluid transfer where cost and flexibility are prioritized.

Chemical Resistance Comparison

Teflon tubing offers superior chemical resistance compared to PVC tubing, with the ability to withstand aggressive solvents, acids, and bases across a wide pH range without degrading. PVC tubing is prone to swelling and brittleness when exposed to strong chemicals, limiting its use in harsh chemical environments. This makes Teflon tubing ideal for applications requiring exposure to highly corrosive substances and extreme temperature variations.

Temperature Tolerance: Teflon vs PVC

Teflon tubing withstands extreme temperatures ranging from -200degC to 260degC, making it ideal for high-temperature applications where PVC tubing, with its limited range of -15degC to 60degC, falls short. This superior thermal resistance ensures Teflon maintains chemical stability and flexibility under intense heat or cold, unlike PVC which can become brittle or deform. Industries requiring durability in harsh thermal environments consistently prefer Teflon tubing over PVC for reliable performance.

Flexibility and Durability Factors

Teflon tubing offers superior chemical resistance and high-temperature tolerance, making it more durable than PVC tubing in harsh environments. While PVC tubing provides excellent flexibility at room temperature, Teflon's flexibility remains consistent across a broader temperature range without cracking or deforming. The exceptional durability and thermal stability of Teflon tubing often make it the preferred choice for industrial applications requiring reliable performance under stress.

Typical Applications of Teflon Tubing

Teflon tubing is widely used in chemical processing, pharmaceuticals, and food industries due to its exceptional chemical resistance and ability to withstand high temperatures up to 260degC (500degF). Its non-stick surface prevents contamination and residue build-up, making it ideal for laboratory equipment and medical devices requiring sterility and purity. Compared to PVC tubing, Teflon tubing excels in applications involving aggressive solvents, corrosive fluids, and high-purity fluid transfer.

Common Uses for PVC Tubing

PVC tubing is widely used in plumbing, irrigation systems, and chemical processing due to its durability, flexibility, and cost-effectiveness. It is commonly employed for water supply lines, air lines, and low-pressure fluid transfer in residential, commercial, and industrial applications. PVC's chemical resistance and ease of installation make it a preferred choice for fluid handling where moderate temperature and pressure conditions are present.

Safety and Compliance Considerations

Teflon tubing offers superior chemical resistance and operates safely at higher temperatures compared to PVC tubing, reducing the risk of leaching harmful substances in sensitive applications. Teflon is compliant with FDA and USP Class VI standards, making it suitable for pharmaceutical and food processing industries, where strict safety regulations apply. In contrast, PVC tubing may release plasticizers and requires careful evaluation for compliance in medical or food-grade environments.

Cost Analysis: Teflon Tubing vs PVC Tubing

Teflon tubing typically costs significantly more than PVC tubing due to its superior chemical resistance, high-temperature tolerance, and durability. PVC tubing offers a more budget-friendly option, suitable for lower temperature and less chemically aggressive environments, making it ideal for cost-sensitive projects. When factoring long-term performance and replacement frequency, Teflon tubing can provide better value despite the higher upfront cost.

Choosing the Right Tubing for Your Application

Teflon tubing offers exceptional chemical resistance and high-temperature tolerance, making it ideal for demanding applications in the pharmaceutical, chemical, and food industries. PVC tubing is more cost-effective and flexible, suited for low-pressure, general-purpose fluid transfer where chemical exposure and temperature extremes are minimal. Selecting between Teflon and PVC tubing requires evaluating application-specific factors such as temperature range, chemical compatibility, and mechanical durability.

Teflon Tubing vs PVC Tubing Infographic

materialdif.com

materialdif.com