Etched Teflon provides enhanced adhesion properties by chemically modifying the surface, improving bonding strength for coatings or adhesives. Skived Teflon, on the other hand, involves mechanically slicing thin sheets from larger blocks, maintaining the inherent non-stick and chemical resistance properties. Choosing between etched and skived Teflon depends on the specific application requirements, such as the need for adhesion versus maintaining surface smoothness and integrity.

Table of Comparison

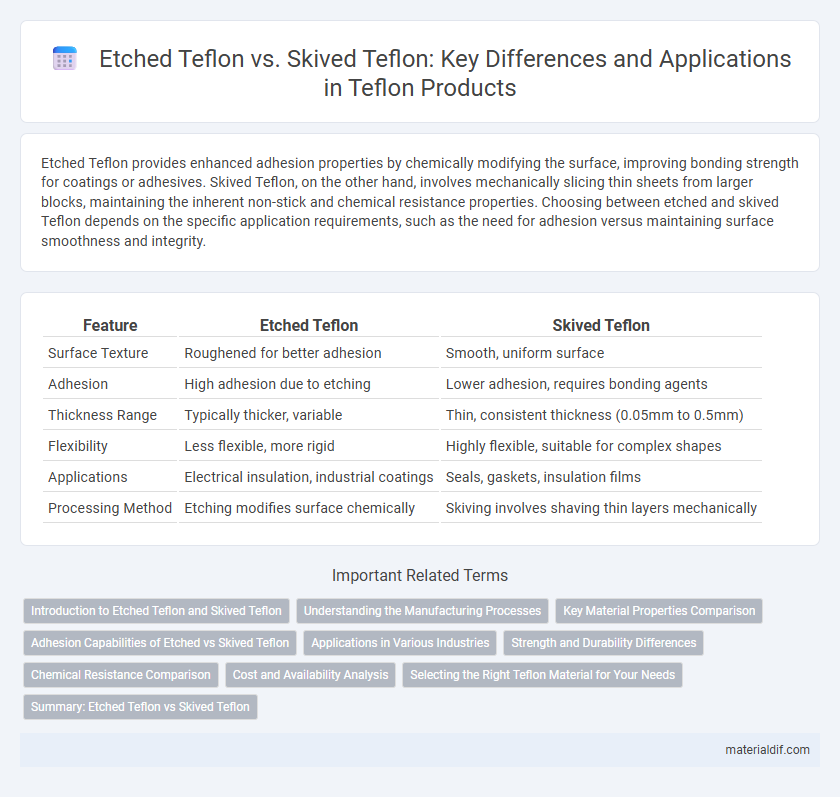

| Feature | Etched Teflon | Skived Teflon |

|---|---|---|

| Surface Texture | Roughened for better adhesion | Smooth, uniform surface |

| Adhesion | High adhesion due to etching | Lower adhesion, requires bonding agents |

| Thickness Range | Typically thicker, variable | Thin, consistent thickness (0.05mm to 0.5mm) |

| Flexibility | Less flexible, more rigid | Highly flexible, suitable for complex shapes |

| Applications | Electrical insulation, industrial coatings | Seals, gaskets, insulation films |

| Processing Method | Etching modifies surface chemically | Skiving involves shaving thin layers mechanically |

Introduction to Etched Teflon and Skived Teflon

Etched Teflon undergoes a chemical treatment process that creates a textured surface to enhance adhesion properties, making it ideal for coatings and bonding applications. Skived Teflon is produced by mechanically slicing thin sheets from Teflon blocks, resulting in uniform, precise thicknesses used extensively in gaskets, seals, and linings. Both variations retain the inherent non-stick, chemical-resistant, and high-temperature capabilities of standard Teflon while offering specialized surface characteristics for distinct industrial uses.

Understanding the Manufacturing Processes

Etched Teflon involves a chemical treatment that microscopically roughens the surface to improve adhesion without compromising the material's inherent non-stick properties. Skived Teflon is produced by mechanically slicing thin layers from a Teflon block, resulting in uniform thickness ideal for precise industrial applications. Understanding these manufacturing processes highlights the balance between surface modification for bonding and maintaining Teflon's chemical resistance and low friction characteristics.

Key Material Properties Comparison

Etched Teflon exhibits enhanced adhesive properties due to its chemically roughened surface, resulting in improved bonding strength compared to the smooth, finely cut surface of Skived Teflon. Skived Teflon maintains superior dimensional stability and uniform thickness, making it ideal for applications requiring precise mechanical tolerances. Both materials retain excellent chemical resistance and low friction, but Etched Teflon's surface treatment optimizes it for lamination and coating processes.

Adhesion Capabilities of Etched vs Skived Teflon

Etched Teflon exhibits superior adhesion capabilities compared to skived Teflon due to its chemically modified surface, which increases surface energy and allows stronger bonding with adhesives and coatings. Skived Teflon, produced by mechanically slicing thin sheets, retains its inert surface, resulting in lower adhesion properties. This enhanced adhesion makes etched Teflon ideal for applications requiring durable bonding in coatings, laminates, and composites.

Applications in Various Industries

Etched Teflon offers enhanced adhesion properties, making it ideal for applications in the electronics industry, such as printed circuit boards and semiconductor manufacturing, where reliable bonding is critical. Skived Teflon, with its precise thickness and smooth finish, is widely used in aerospace and chemical processing for gaskets, seals, and insulation films that require chemical resistance and dimensional stability. Both types enable tailored solutions across automotive, medical, and industrial sectors, optimizing performance under extreme environmental conditions.

Strength and Durability Differences

Etched Teflon surfaces feature a chemically treated texture that significantly enhances adhesion strength in bonding applications, making them more durable under mechanical stress compared to smooth surfaces. Skived Teflon, produced by mechanically slicing thin films from Teflon blocks, maintains high tensile strength and uniform thickness but offers less surface roughness, resulting in weaker adhesive bonding properties. The chemical etching process optimizes durability for use in harsh environments where enhanced bonding and abrasion resistance are critical.

Chemical Resistance Comparison

Etched Teflon exhibits superior chemical resistance due to its enhanced surface texture, which improves adhesion properties without compromising the inherent non-reactive nature of the polymer. Skived Teflon maintains excellent resistance to most chemicals but can have minor surface irregularities affecting uniform protection in aggressive environments. Both types resist acids, bases, and solvents effectively, yet etched Teflon's surface modification provides a more robust barrier against chemical degradation in demanding applications.

Cost and Availability Analysis

Etched Teflon offers enhanced adhesion properties due to its surface treatment, but the manufacturing process increases production costs, making it less cost-effective than skived Teflon. Skived Teflon, produced by mechanically slicing Teflon sheets, is widely available and generally lower in price due to its simpler and faster production technique. Cost-sensitive applications often favor skived Teflon for its balance of performance and availability, while etched Teflon is selected when superior bonding is critical despite higher expenses.

Selecting the Right Teflon Material for Your Needs

Etched Teflon features a chemically treated surface that enhances adhesion, making it ideal for applications requiring strong bonding with adhesives or coatings. Skived Teflon is produced by slicing thin films from a Teflon block, providing a smooth, uniform surface suitable for high-performance sealing and insulating components. Selecting the right Teflon material depends on surface adhesion requirements and mechanical precision, with etched variants favored for bonding and skived types preferred for dimensional consistency and strength.

Summary: Etched Teflon vs Skived Teflon

Etched Teflon features a chemically treated surface that enhances adhesion properties, making it ideal for applications requiring strong bonding with adhesives or coatings. Skived Teflon involves mechanically sliced sheets that maintain smooth, uniform thickness and excellent dielectric properties for precise electrical insulation. The choice between etched and skived Teflon depends on the need for surface adhesion versus dimensional control and electrical performance.

Etched Teflon vs Skived Teflon Infographic

materialdif.com

materialdif.com