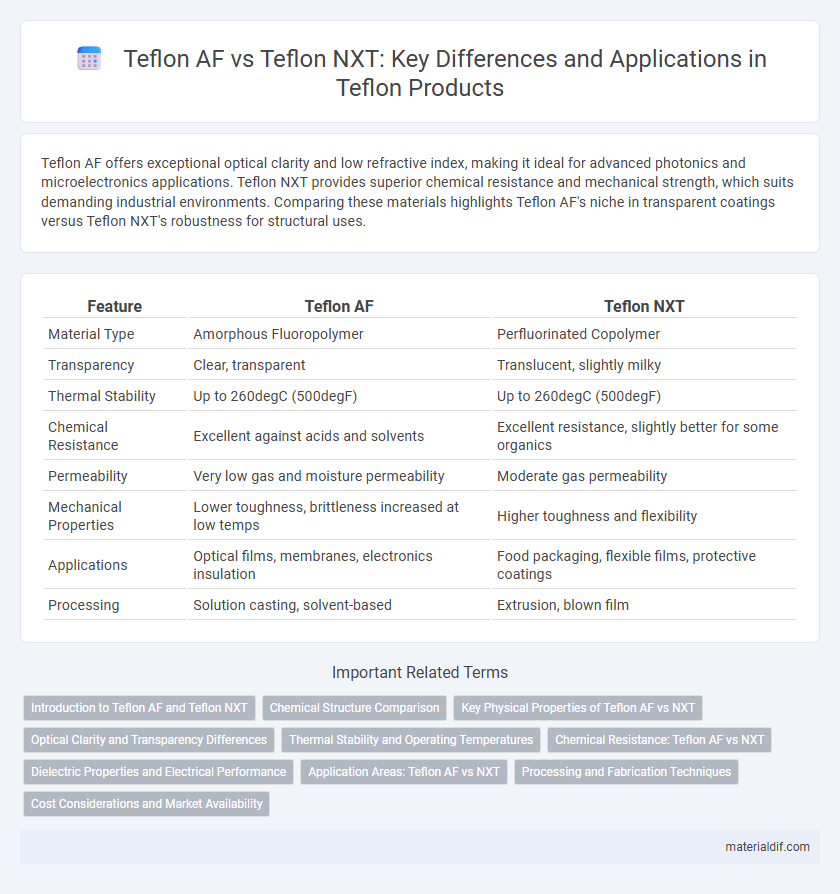

Teflon AF offers exceptional optical clarity and low refractive index, making it ideal for advanced photonics and microelectronics applications. Teflon NXT provides superior chemical resistance and mechanical strength, which suits demanding industrial environments. Comparing these materials highlights Teflon AF's niche in transparent coatings versus Teflon NXT's robustness for structural uses.

Table of Comparison

| Feature | Teflon AF | Teflon NXT |

|---|---|---|

| Material Type | Amorphous Fluoropolymer | Perfluorinated Copolymer |

| Transparency | Clear, transparent | Translucent, slightly milky |

| Thermal Stability | Up to 260degC (500degF) | Up to 260degC (500degF) |

| Chemical Resistance | Excellent against acids and solvents | Excellent resistance, slightly better for some organics |

| Permeability | Very low gas and moisture permeability | Moderate gas permeability |

| Mechanical Properties | Lower toughness, brittleness increased at low temps | Higher toughness and flexibility |

| Applications | Optical films, membranes, electronics insulation | Food packaging, flexible films, protective coatings |

| Processing | Solution casting, solvent-based | Extrusion, blown film |

Introduction to Teflon AF and Teflon NXT

Teflon AF is an amorphous fluoropolymer known for its exceptional optical clarity and low refractive index, making it ideal for high-performance optical and microelectronic applications. Teflon NXT is a melt-processable fluoropolymer offering superior chemical resistance and mechanical durability in more flexible forms suitable for coating and film applications. Both materials deliver unique properties tailored to advanced engineering needs, with Teflon AF excelling in transparency and Teflon NXT in processability and robustness.

Chemical Structure Comparison

Teflon AF consists of amorphous fluoropolymer copolymers with a high fluorine content, primarily composed of tetrafluoroethylene and 2,2-bis(trifluoromethyl)-4,5-difluoro-1,3-dioxole units, providing exceptional optical clarity and low dielectric constants. In contrast, Teflon NXT is engineered from a different fluoropolymer architecture designed for enhanced mechanical strength and durability, featuring a distinct fluorinated backbone that balances chemical resistance with improved thermal stability. The chemical structure differences between Teflon AF and Teflon NXT influence their respective performance in applications requiring specific combinations of transparency, flexibility, and chemical inertness.

Key Physical Properties of Teflon AF vs NXT

Teflon AF exhibits exceptional optical clarity and high gas permeability due to its amorphous fluoropolymer structure, while Teflon NXT offers enhanced mechanical strength and impact resistance with a semi-crystalline fluoropolymer composition. Teflon AF typically shows lower density and higher dielectric constant compared to Teflon NXT, making it suitable for applications requiring superior transparency and electrical insulation. In contrast, Teflon NXT's thermal stability and chemical resistance are better suited for demanding industrial environments where mechanical durability is critical.

Optical Clarity and Transparency Differences

Teflon AF exhibits superior optical clarity and higher transparency compared to Teflon NXT, making it ideal for applications requiring minimal light distortion and maximum light transmission. The amorphous structure of Teflon AF reduces birefringence and scattering, enhancing its performance in optical devices and coatings. In contrast, Teflon NXT has slightly lower transparency due to its semi-crystalline nature, which can cause increased light scattering and reduced clarity.

Thermal Stability and Operating Temperatures

Teflon AF exhibits superior thermal stability with a continuous operating temperature range reaching up to 260degC, making it ideal for high-temperature applications. In contrast, Teflon NXT offers enhanced flexibility but has a lower maximum operating temperature around 150degC, limiting its use in extreme heat environments. Choosing between the two depends on the required thermal endurance and application-specific temperature demands.

Chemical Resistance: Teflon AF vs NXT

Teflon AF exhibits superior chemical resistance compared to Teflon NXT, particularly against aggressive solvents and harsh acids, making it ideal for demanding industrial applications. Teflon NXT offers enhanced mechanical properties but has slightly reduced resistance to strong oxidizers and organic solvents compared to Teflon AF. The unique amorphous fluoropolymer structure of Teflon AF contributes to its outstanding chemical inertness, ensuring extended durability in corrosive environments.

Dielectric Properties and Electrical Performance

Teflon AF offers superior dielectric properties with an exceptionally low dielectric constant around 1.3 and excellent electrical insulation, making it ideal for high-frequency applications requiring minimal signal loss. Teflon NXT, while maintaining good dielectric strength and thermal stability, exhibits slightly higher dielectric constant values, typically near 2.0, balancing flexibility and electrical performance. The choice between Teflon AF and Teflon NXT depends on specific electrical performance needs, with Teflon AF preferred for ultra-low dielectric loss and Teflon NXT favored for enhanced mechanical properties alongside reliable insulation.

Application Areas: Teflon AF vs NXT

Teflon AF is widely used in optical coatings, membranes, and microelectronics due to its exceptional transparency and low dielectric constant, enhancing performance in high-frequency applications. Teflon NXT finds applications in chemical processing and industrial coatings, valued for its chemical resistance and mechanical durability under harsh environmental conditions. Both materials serve specialized roles, with Teflon AF excelling in high-tech, precision fields and Teflon NXT preferred for robust, chemically exposed industrial uses.

Processing and Fabrication Techniques

Teflon AF and Teflon NXT differ significantly in processing and fabrication techniques due to their distinct molecular structures; Teflon AF, an amorphous fluoropolymer, requires precise solvent casting or plasma-enhanced chemical vapor deposition for thin-film applications. Teflon NXT, a chemically modified polytetrafluoroethylene (PTFE), enables easier mechanical processing like extrusion and molding, offering enhanced flexibility in forming complex shapes and coatings. These differences impact manufacturing efficiency, with Teflon NXT favoring bulk fabrication and Teflon AF excelling in specialized microfabrication and high-performance coating processes.

Cost Considerations and Market Availability

Teflon AF generally incurs higher costs due to its specialized fluoropolymer properties and limited large-scale production, making it less accessible in common industrial markets. In contrast, Teflon NXT offers a more cost-effective solution with broader market availability, benefiting from streamlined manufacturing and wider supplier distribution. The choice between Teflon AF and Teflon NXT often hinges on budget constraints and the immediacy of procurement needs within specific application contexts.

Teflon AF vs Teflon NXT Infographic

materialdif.com

materialdif.com