Sheet Teflon offers exceptional chemical resistance and is ideal for applications requiring flat, flexible, or cut-to-size materials, while Rod Teflon provides superior strength and durability for machining into precise components such as bearings and bushings. Sheet Teflon is preferred for sealing, lining, and insulation tasks due to its easy handling and versatility, whereas Rod Teflon excels in structural uses where dimensional stability and load-bearing capacity are critical. Selecting between Sheet and Rod Teflon depends on the specific requirements of flexibility, strength, and machining needs in your project.

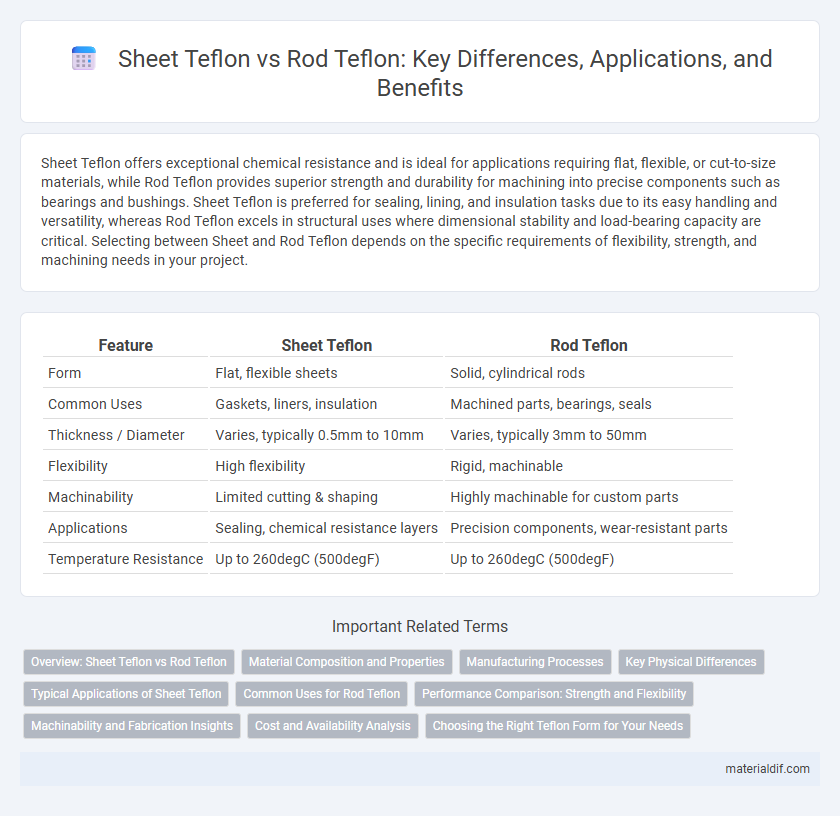

Table of Comparison

| Feature | Sheet Teflon | Rod Teflon |

|---|---|---|

| Form | Flat, flexible sheets | Solid, cylindrical rods |

| Common Uses | Gaskets, liners, insulation | Machined parts, bearings, seals |

| Thickness / Diameter | Varies, typically 0.5mm to 10mm | Varies, typically 3mm to 50mm |

| Flexibility | High flexibility | Rigid, machinable |

| Machinability | Limited cutting & shaping | Highly machinable for custom parts |

| Applications | Sealing, chemical resistance layers | Precision components, wear-resistant parts |

| Temperature Resistance | Up to 260degC (500degF) | Up to 260degC (500degF) |

Overview: Sheet Teflon vs Rod Teflon

Sheet Teflon offers a flat, uniform surface ideal for gaskets, seals, and insulation applications, providing exceptional chemical resistance and low friction. Rod Teflon is cylindrical, suited for machining into custom parts like bearings, bushings, and washers, maintaining the material's strength and durability. Both forms maintain high thermal stability and non-reactive properties, with the choice depending on the specific dimensional and mechanical requirements of the application.

Material Composition and Properties

Sheet Teflon and Rod Teflon both consist primarily of polytetrafluoroethylene (PTFE), known for its exceptional chemical resistance, low friction, and high thermal stability. Sheet Teflon typically offers uniform thickness and smooth surfaces ideal for gasket and insulation applications, while Rod Teflon features higher density and mechanical strength suited for machining into custom parts. Both forms maintain excellent non-stick properties and electrical insulation, with slight variations in physical form influencing their specific industrial uses.

Manufacturing Processes

Sheet Teflon is produced through a calendaring process where molten PTFE is extruded and compressed into thin, uniform sheets, allowing precise thickness control for industrial applications. Rod Teflon manufacturing involves ram extrusion or compression molding, where PTFE powder is shaped into solid cylindrical forms and sintered to achieve high density and mechanical strength. Both processes require careful temperature regulation during sintering to enhance the material's durability and chemical resistance.

Key Physical Differences

Sheet Teflon features a flat, uniform thickness ideal for gasket applications, while Rod Teflon offers a cylindrical shape suited for machining into precise components. Sheet Teflon exhibits consistent surface smoothness and is typically available in thicknesses ranging from 0.5 mm to several millimeters. Rod Teflon, often supplied in diameters from 6 mm to 100 mm, provides superior mechanical strength and can be tailored into complex shapes with high dimensional accuracy.

Typical Applications of Sheet Teflon

Sheet Teflon is commonly used in gasket manufacturing, chemical tank linings, and insulation layers due to its excellent chemical resistance and non-stick properties. It serves as a protective barrier in pharmaceutical and food processing industries where contamination must be minimized. Unlike rod Teflon, sheets provide customizable thickness and flexibility for sealing and lining varied industrial applications.

Common Uses for Rod Teflon

Rod Teflon is commonly used in applications requiring precision machining for components like seals, bearings, and bushings due to its excellent chemical resistance and low friction properties. Its solid cylindrical form allows for easy customization into parts used in industries such as automotive, chemical processing, and food manufacturing. Rod Teflon's durability and non-reactive surface make it ideal for creating durable mechanical parts exposed to harsh environments.

Performance Comparison: Strength and Flexibility

Sheet Teflon offers superior flexibility, making it ideal for applications requiring bending and shaping without cracking, while Rod Teflon provides greater tensile strength suited for structural components and machining precision parts. The sheet's thinner profile enhances its adaptability in gasketing and lining uses, whereas the rod's dense, solid form ensures durability and load-bearing capacity under high stress. Both materials exhibit excellent chemical resistance and thermal stability, but selection depends on whether flexibility or mechanical strength is paramount for the intended application.

Machinability and Fabrication Insights

Sheet Teflon offers superior machinability for large, flat components with consistent thickness, enabling precise cutting, drilling, and shaping for industrial applications. Rod Teflon is ideal for fabrication requiring cylindrical parts, allowing for easy turning, grinding, and milling to achieve complex geometries. Both forms exhibit excellent chemical resistance and low friction, but selection depends on part design and machining requirements.

Cost and Availability Analysis

Sheet Teflon often offers a lower cost per unit area compared to Rod Teflon, making it more economical for applications requiring large surface coverage. Rod Teflon, while generally more expensive due to machining complexities, provides easier customization for precision components. Availability of Sheet Teflon is typically higher due to mass production, whereas Rod Teflon may have longer lead times depending on size and grade specifications.

Choosing the Right Teflon Form for Your Needs

Sheet Teflon offers excellent surface coverage and is ideal for applications requiring large, flat areas with chemical resistance and low friction, such as gaskets and linings. Rod Teflon provides superior strength and is suitable for machining into custom parts like seals, bearings, and wear strips that demand precision and durability. Selecting the right Teflon form depends on the specific application's structural and dimensional requirements, ensuring optimal performance and longevity.

Sheet Teflon vs Rod Teflon Infographic

materialdif.com

materialdif.com