Teflon envelope gaskets provide superior chemical resistance and flexibility compared to solid gaskets, making them ideal for sealing applications in harsh environments. Their unique design allows for effective sealing with minimal compression, reducing the risk of damage and extending gasket life. Solid gaskets offer durability and strength but may lack the adaptability and chemical inertness found in Teflon envelope gaskets, leading to potential leaks under extreme conditions.

Table of Comparison

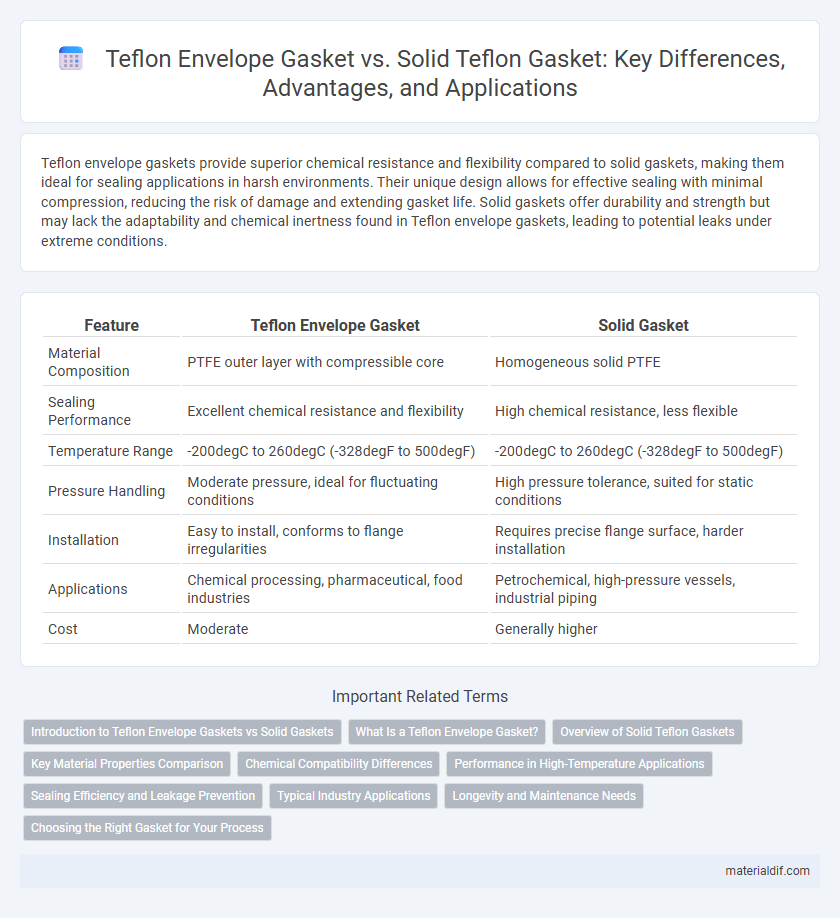

| Feature | Teflon Envelope Gasket | Solid Gasket |

|---|---|---|

| Material Composition | PTFE outer layer with compressible core | Homogeneous solid PTFE |

| Sealing Performance | Excellent chemical resistance and flexibility | High chemical resistance, less flexible |

| Temperature Range | -200degC to 260degC (-328degF to 500degF) | -200degC to 260degC (-328degF to 500degF) |

| Pressure Handling | Moderate pressure, ideal for fluctuating conditions | High pressure tolerance, suited for static conditions |

| Installation | Easy to install, conforms to flange irregularities | Requires precise flange surface, harder installation |

| Applications | Chemical processing, pharmaceutical, food industries | Petrochemical, high-pressure vessels, industrial piping |

| Cost | Moderate | Generally higher |

Introduction to Teflon Envelope Gaskets vs Solid Gaskets

Teflon envelope gaskets consist of a flexible Teflon (PTFE) outer layer encasing a metallic core, combining chemical resistance with structural strength for sealing applications. Solid Teflon gaskets are made entirely of PTFE, offering excellent corrosion resistance but limited mechanical strength compared to envelope types. The choice between Teflon envelope gaskets and solid gaskets depends on factors such as pressure, temperature, and chemical compatibility in industrial sealing environments.

What Is a Teflon Envelope Gasket?

A Teflon envelope gasket is a specialized sealing component consisting of a flexible metal core completely encased in a pure Teflon (PTFE) outer layer, combining metal strength with chemical resistance. This design allows the gasket to withstand aggressive chemicals, extreme temperatures, and pressure variations, making it ideal for corrosive environments in chemical processing industries. Compared to solid Teflon gaskets, envelope gaskets offer enhanced mechanical durability and better sealing performance under mechanical stress.

Overview of Solid Teflon Gaskets

Solid Teflon gaskets are crafted from pure polytetrafluoroethylene material, offering exceptional chemical resistance and temperature tolerance up to 260degC (500degF). Unlike Teflon envelope gaskets, which combine a soft sealing material encased in a Teflon jacket, solid gaskets provide a uniform, durable sealing solution ideal for aggressive media and high-pressure environments. Their non-porous, inert nature ensures long-lasting performance in demanding applications across the chemical, pharmaceutical, and food processing industries.

Key Material Properties Comparison

Teflon envelope gaskets offer superior chemical resistance and flexibility compared to solid gaskets, making them ideal for sealing in aggressive chemical environments. Their non-porous structure provides excellent impermeability, while solid gaskets, often made from compressed fiber or rubber, provide higher mechanical strength and temperature resistance. The choice between Teflon envelope and solid gaskets depends on application requirements such as temperature range, pressure, and exposure to corrosive substances.

Chemical Compatibility Differences

Teflon envelope gaskets offer superior chemical resistance compared to solid gaskets due to their encapsulated design, which protects the core material from aggressive chemicals and prevents corrosion. Solid gaskets made entirely of Teflon provide excellent chemical compatibility with a broad range of acids, bases, and solvents but may experience mechanical deformation in aggressive environments. The envelope construction enhances durability and longevity in harsh chemical applications by isolating the sealing material from direct contact with reactive substances.

Performance in High-Temperature Applications

Teflon envelope gaskets outperform solid gaskets in high-temperature applications due to their superior chemical resistance and dimensional stability up to 260degC (500degF). The flexible nature of envelope gaskets allows for better sealing under thermal expansion and contraction, reducing leak risks in dynamic environments. Solid gaskets may degrade or lose sealing integrity faster when exposed to rapid temperature fluctuations or aggressive chemicals.

Sealing Efficiency and Leakage Prevention

Teflon envelope gaskets provide superior sealing efficiency by offering flexibility that conforms to uneven flange surfaces, significantly reducing leakage risks compared to solid gaskets. The envelope design encases a compressible filler, enhancing the gasket's ability to maintain a tight seal under varying pressure and temperature conditions. Solid Teflon gaskets, while chemically resistant, can struggle with achieving uniform compression, making them less effective in preventing leaks in dynamic or irregular sealing environments.

Typical Industry Applications

Teflon envelope gaskets are widely used in chemical processing, pharmaceuticals, and food industries where contamination prevention and chemical resistance are critical, as their design provides superior sealing around irregular surfaces and flange imperfections. Solid Teflon gaskets are preferred in applications requiring high purity and strong resistance to aggressive chemicals, such as semiconductor manufacturing and aggressive acid handling. Both types offer excellent non-stick properties, but envelope gaskets excel in dynamic or non-uniform flange environments while solid gaskets are ideal for rigid, static sealing needs.

Longevity and Maintenance Needs

Teflon envelope gaskets offer superior longevity due to their flexible, thin design that resists cracking and deformation under stress, unlike solid gaskets which may wear out faster with repeated compression. Maintenance for Teflon envelope gaskets is minimal since their non-porous surface prevents chemical degradation and buildup, reducing the need for frequent replacements. Solid gaskets require more regular inspections and maintenance to prevent leaks caused by physical wear and material fatigue over time.

Choosing the Right Gasket for Your Process

Teflon envelope gaskets offer superior chemical resistance and flexibility, making them ideal for processes involving aggressive chemicals or fluctuating temperatures. Solid Teflon gaskets, while durable and providing excellent sealing performance, are better suited for stable operating conditions with consistent pressure and temperature. Selecting the right gasket depends on evaluating process parameters such as chemical exposure, temperature variations, and mechanical stress to ensure optimal sealing and longevity.

Teflon Envelope Gasket vs Solid Gasket Infographic

materialdif.com

materialdif.com