Teflon sheets provide a durable, non-stick surface ideal for applications requiring large coverage and heat resistance, while Teflon tape is designed for sealing pipe threads to prevent leaks in plumbing and industrial uses. The sheet's thickness allows for better insulation and wear resistance, whereas the tape's thin, flexible form makes it easy to wrap and conform to irregular shapes. Choosing between Teflon sheet and tape depends on whether the priority is surface protection or tight sealing in fluid systems.

Table of Comparison

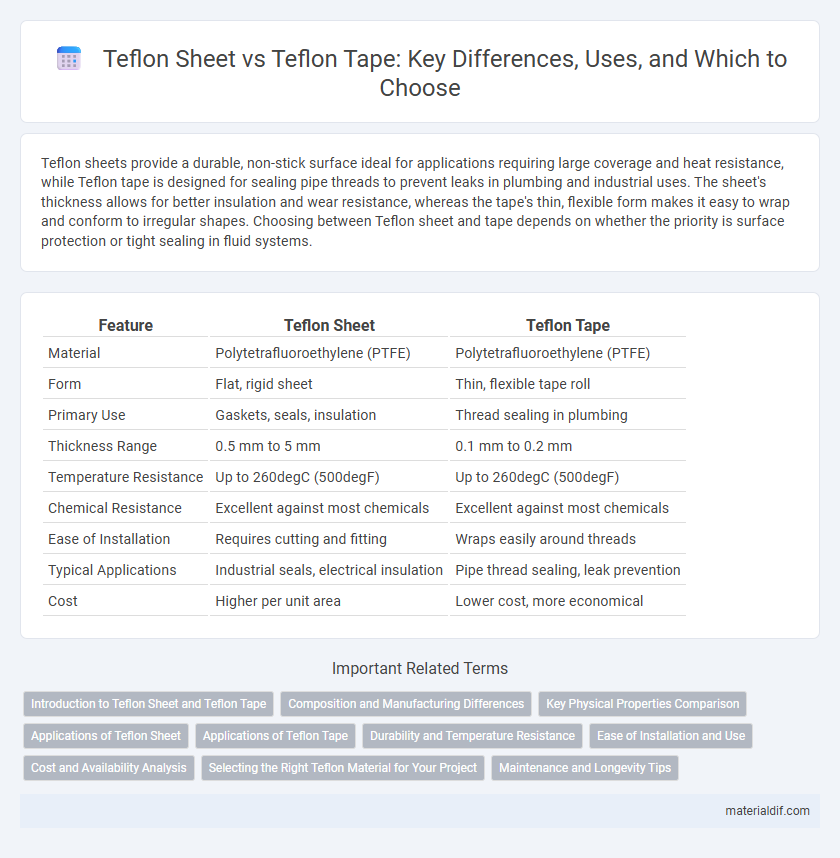

| Feature | Teflon Sheet | Teflon Tape |

|---|---|---|

| Material | Polytetrafluoroethylene (PTFE) | Polytetrafluoroethylene (PTFE) |

| Form | Flat, rigid sheet | Thin, flexible tape roll |

| Primary Use | Gaskets, seals, insulation | Thread sealing in plumbing |

| Thickness Range | 0.5 mm to 5 mm | 0.1 mm to 0.2 mm |

| Temperature Resistance | Up to 260degC (500degF) | Up to 260degC (500degF) |

| Chemical Resistance | Excellent against most chemicals | Excellent against most chemicals |

| Ease of Installation | Requires cutting and fitting | Wraps easily around threads |

| Typical Applications | Industrial seals, electrical insulation | Pipe thread sealing, leak prevention |

| Cost | Higher per unit area | Lower cost, more economical |

Introduction to Teflon Sheet and Teflon Tape

Teflon sheet is a flat, flexible material made from polytetrafluoroethylene (PTFE) commonly used for lining, gasketing, and insulation due to its high chemical resistance and non-stick properties. Teflon tape, also known as PTFE tape or plumber's tape, is a thin, white film used primarily to seal pipe threads and prevent leaks in plumbing applications. Both products leverage the unique low-friction and heat-resistant characteristics of Teflon but serve distinct purposes based on their form and application requirements.

Composition and Manufacturing Differences

Teflon sheets are typically made from expanded polytetrafluoroethylene (ePTFE), offering a dense, non-porous surface produced through high-temperature sintering, which results in flexible yet durable sheets ideal for sealing and insulation. In contrast, Teflon tape is composed of thin layers of PTFE film, manufactured by stretching and calendaring processes that create a thin, adhesive-free, semi-transparent tape primarily used for thread sealing in plumbing. The difference in manufacturing techniques leads to distinct physical properties, with sheets providing robust mechanical strength and tapes offering conformability and ease of application in threaded connections.

Key Physical Properties Comparison

Teflon sheets exhibit high durability, excellent chemical resistance, and a smooth surface ideal for gasketing and insulation applications, whereas Teflon tape offers superior flexibility, conformability, and ease of sealing pipe threads. The sheet thickness ranges from 0.5 mm to several millimeters, providing robust mechanical strength, while the tape is typically thin and stretches to ensure a tight seal. Both materials share a low coefficient of friction and thermal stability up to 260degC, but their physical form and mechanical properties dictate distinct industrial uses.

Applications of Teflon Sheet

Teflon sheets are widely used in industrial applications requiring chemical resistance, non-stick surfaces, and high-temperature tolerance, such as gaskets, liners, and insulation. These sheets offer excellent electrical insulation properties and are ideal for protecting equipment in harsh environments. Unlike Teflon tape, which primarily serves as a thread sealant, Teflon sheets provide durable, flat coverage for sealing and cushioning in machinery and chemical processing.

Applications of Teflon Tape

Teflon tape, commonly known as PTFE tape, is widely used for sealing pipe threads in plumbing and gas fittings due to its excellent chemical resistance and low friction properties. Its thin, flexible form allows for easy wrapping around threaded connections, preventing leaks and ensuring a tight seal in high-pressure environments. This tape is essential in applications requiring quick, reliable sealing solutions, especially in water, air, and hydraulic systems.

Durability and Temperature Resistance

Teflon sheets offer superior durability and can withstand continuous exposure to temperatures up to 260degC, making them ideal for heavy-duty industrial applications. Teflon tape, while also resistant to high temperatures around 260degC, provides less mechanical strength and is primarily used as a sealing material rather than for structural support. The density and thickness of Teflon sheets contribute to their enhanced robustness compared to the thin, flexible nature of Teflon tape.

Ease of Installation and Use

Teflon sheets offer straightforward installation with their flexible, non-adhesive surface that can be easily cut and molded to cover larger areas or irregular shapes. Teflon tape provides quick application by wrapping tightly around threaded pipes and fittings, ensuring a secure seal without the need for additional tools. Tape is preferred for small-scale sealing tasks due to its convenience, while sheets excel in protective or non-stick applications requiring customizable coverage.

Cost and Availability Analysis

Teflon sheets generally incur higher costs due to their larger size and thickness, making them ideal for industrial applications requiring durable, heat-resistant surfaces. In contrast, Teflon tape is more affordable and widely available in rolls, catering to plumbing and sealing needs with ease of application. Availability of Teflon tape is broader across retail and online stores, while Teflon sheets are often sourced from specialized suppliers.

Selecting the Right Teflon Material for Your Project

Teflon sheets offer a durable, non-stick surface ideal for larger applications requiring heat resistance and chemical inertness, while Teflon tape provides a flexible, easy-to-apply sealing solution for threaded pipe joints. Selecting the right Teflon material depends on project requirements such as temperature tolerance, mechanical strength, and ease of installation. Consider factors like sheet thickness, tape width, and the specific environmental exposure to ensure optimal performance and longevity.

Maintenance and Longevity Tips

Teflon sheets require regular cleaning with mild detergents to maintain their non-stick properties and prevent surface degradation. Teflon tapes, often used for sealing, benefit from proper storage in a cool, dry place to avoid brittleness and ensure effective sealing over time. Both materials last longer when protected from excessive heat and abrasive contact, preserving their chemical resistance and structural integrity.

Teflon Sheet vs Teflon Tape Infographic

materialdif.com

materialdif.com