Expanded PTFE (ePTFE) offers a porous, breathable structure that enhances flexibility and chemical resistance compared to standard PTFE, making it ideal for sealing and gasketing in pet applications. Standard PTFE provides excellent chemical inertness and high-temperature resistance but lacks the expanded variant's tensile strength and permeability. Choosing ePTFE ensures improved durability and performance in dynamic environments where pets may encounter varied conditions.

Table of Comparison

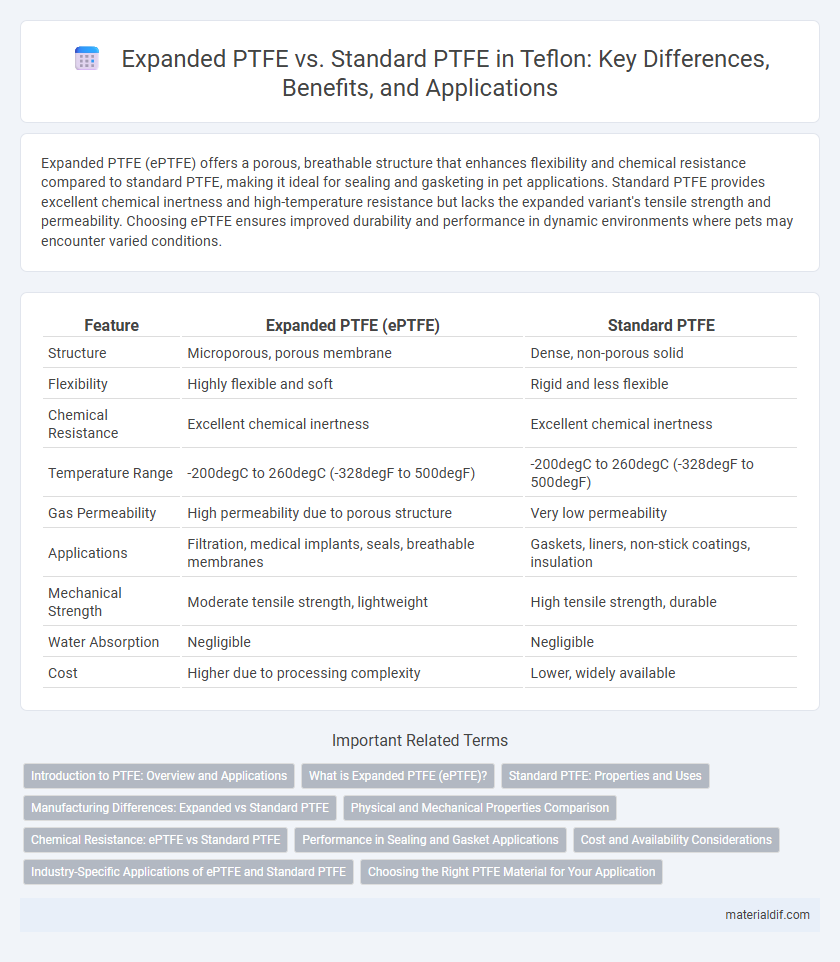

| Feature | Expanded PTFE (ePTFE) | Standard PTFE |

|---|---|---|

| Structure | Microporous, porous membrane | Dense, non-porous solid |

| Flexibility | Highly flexible and soft | Rigid and less flexible |

| Chemical Resistance | Excellent chemical inertness | Excellent chemical inertness |

| Temperature Range | -200degC to 260degC (-328degF to 500degF) | -200degC to 260degC (-328degF to 500degF) |

| Gas Permeability | High permeability due to porous structure | Very low permeability |

| Applications | Filtration, medical implants, seals, breathable membranes | Gaskets, liners, non-stick coatings, insulation |

| Mechanical Strength | Moderate tensile strength, lightweight | High tensile strength, durable |

| Water Absorption | Negligible | Negligible |

| Cost | Higher due to processing complexity | Lower, widely available |

Introduction to PTFE: Overview and Applications

Expanded PTFE (ePTFE) features a microporous structure created through mechanical expansion, offering enhanced flexibility, breathability, and superior chemical resistance compared to standard PTFE. Standard PTFE, known for its outstanding non-stick properties, high thermal stability up to 260degC, and excellent dielectric strength, is widely used in cookware, electrical insulation, and chemical processing. Both forms exhibit exceptional corrosion resistance and low friction coefficients, with ePTFE preferred in medical implants, filtration, and performance textiles due to its porous architecture.

What is Expanded PTFE (ePTFE)?

Expanded PTFE (ePTFE) is a porous form of polytetrafluoroethylene created by stretching standard PTFE, which results in a microstructure with millions of tiny pores. This unique structure grants ePTFE enhanced breathability, flexibility, and superior filtration capabilities compared to standard PTFE. ePTFE is widely used in medical implants, filtration systems, and high-performance membranes due to its biocompatibility and chemical resistance.

Standard PTFE: Properties and Uses

Standard PTFE is characterized by its exceptional chemical resistance, low friction coefficient, and high thermal stability, making it ideal for applications in harsh environments such as chemical processing and food industry equipment. It exhibits excellent electrical insulation properties and a wide operating temperature range from -200degC to 260degC. Common uses include non-stick cookware coatings, gaskets, seals, and insulating materials in electrical wiring.

Manufacturing Differences: Expanded vs Standard PTFE

Expanded PTFE (ePTFE) is produced by mechanically stretching standard PTFE under controlled conditions, creating a microporous structure with increased surface area and enhanced permeability. Standard PTFE is manufactured through a sintering process that fuses polymer particles into a dense, non-porous solid without altering its molecular structure. The stretching in expanded PTFE manufacturing aligns polymer chains, improving tensile strength and flexibility compared to the rigid and chemically inert standard PTFE form.

Physical and Mechanical Properties Comparison

Expanded PTFE (ePTFE) exhibits significantly higher tensile strength and superior flexibility compared to standard PTFE due to its microporous structure, enhancing durability in dynamic applications. The expansion process increases surface area and porosity, resulting in improved gas permeability and lower density, while maintaining excellent chemical resistance inherent to PTFE. Standard PTFE typically has higher stiffness and compressive strength but lacks the enhanced elongation and fracture toughness presented by expanded PTFE's fibrillated morphology.

Chemical Resistance: ePTFE vs Standard PTFE

Expanded PTFE (ePTFE) retains the exceptional chemical resistance of standard PTFE, effectively resisting acids, bases, and organic solvents across a wide temperature range. Unlike standard PTFE, ePTFE's microporous structure enhances its chemical compatibility by providing improved permeation resistance and reduced swelling in aggressive chemical environments. This combination of durability and chemical inertness makes ePTFE ideal for applications requiring both flexibility and superior chemical resistance.

Performance in Sealing and Gasket Applications

Expanded PTFE (ePTFE) offers superior conformability and enhanced sealing performance compared to standard PTFE due to its microporous structure, which allows better compression and recovery in gasket applications. Its increased flexibility and resistance to creep reduce leakage risks and improve long-term durability under fluctuating pressures and temperatures. Standard PTFE, while chemically resistant, lacks the same level of elasticity and sealing efficiency required for high-performance gasket use.

Cost and Availability Considerations

Expanded PTFE (ePTFE) is generally more expensive than standard PTFE due to its specialized manufacturing process, which enhances its porosity and flexibility. Availability of ePTFE can be more limited compared to standard PTFE, as it is produced by fewer suppliers and used in niche applications like medical implants and high-performance filtration. Standard PTFE is widely available, cost-effective, and suitable for a broader range of industrial applications, making it the preferred choice when budget and accessibility are major concerns.

Industry-Specific Applications of ePTFE and Standard PTFE

Expanded PTFE (ePTFE) offers superior porosity and flexibility compared to standard PTFE, making it ideal for filtration systems in chemical processing and breathable medical implants. Standard PTFE is widely used in industrial applications requiring excellent chemical resistance and low friction, such as gaskets, seals, and non-stick coatings in food manufacturing. Industries like automotive and electronics leverage ePTFE for its microporous membranes and conductive properties, whereas standard PTFE dominates in high-temperature and aggressive chemical environments.

Choosing the Right PTFE Material for Your Application

Expanded PTFE (ePTFE) offers enhanced porosity and flexibility compared to standard PTFE, making it ideal for applications requiring superior sealing and filtration. Standard PTFE provides excellent chemical resistance and thermal stability, suitable for general-purpose gaskets and insulation. Selecting the right PTFE material depends on specific application needs such as pressure tolerance, chemical exposure, and mechanical stress.

Expanded PTFE vs Standard PTFE Infographic

materialdif.com

materialdif.com