Teflon encapsulation involves fully enclosing materials in a durable Teflon layer, providing superior chemical resistance and long-lasting protection against corrosion and wear. Teflon lamination, by contrast, applies a thin Teflon film bonded to the surface, offering flexibility and ease of application but with less robust protection. Choosing between encapsulation and lamination depends on the required durability and specific environmental challenges faced by the Teflon pet product.

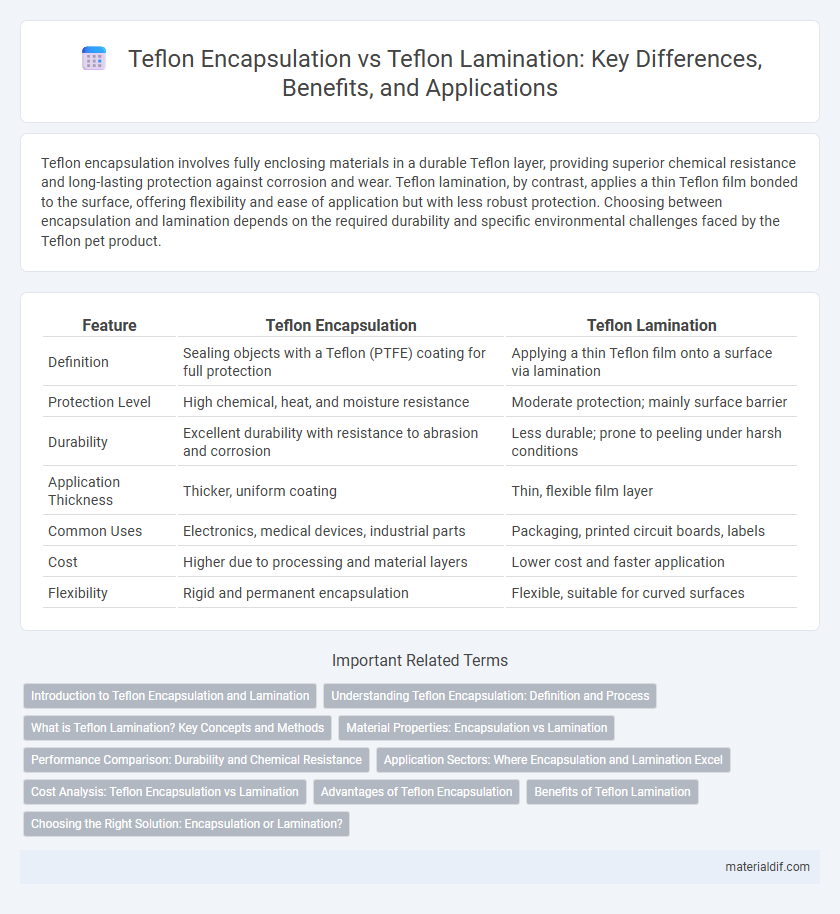

Table of Comparison

| Feature | Teflon Encapsulation | Teflon Lamination |

|---|---|---|

| Definition | Sealing objects with a Teflon (PTFE) coating for full protection | Applying a thin Teflon film onto a surface via lamination |

| Protection Level | High chemical, heat, and moisture resistance | Moderate protection; mainly surface barrier |

| Durability | Excellent durability with resistance to abrasion and corrosion | Less durable; prone to peeling under harsh conditions |

| Application Thickness | Thicker, uniform coating | Thin, flexible film layer |

| Common Uses | Electronics, medical devices, industrial parts | Packaging, printed circuit boards, labels |

| Cost | Higher due to processing and material layers | Lower cost and faster application |

| Flexibility | Rigid and permanent encapsulation | Flexible, suitable for curved surfaces |

Introduction to Teflon Encapsulation and Lamination

Teflon encapsulation involves fully surrounding electronic components or materials with a protective Teflon coating to provide superior chemical resistance and electrical insulation. Teflon lamination, by contrast, applies a thin Teflon film layer bonded onto surfaces, enhancing surface durability and non-stick properties without complete enclosure. Both processes leverage polytetrafluoroethylene's (PTFE) unique characteristics, but encapsulation offers more comprehensive protection while lamination is favored for lightweight, flexible applications.

Understanding Teflon Encapsulation: Definition and Process

Teflon encapsulation involves fully enclosing electronic components or materials in a protective Teflon polymer layer through processes like dip coating or spray coating, providing superior chemical resistance and insulation. This method creates a seamless, conformal barrier that prevents moisture, dust, and corrosive agents from reaching the encapsulated surfaces. Compared to Teflon lamination, which bonds thin Teflon films onto substrates, encapsulation offers more comprehensive protection for complex shapes and delicate assemblies.

What is Teflon Lamination? Key Concepts and Methods

Teflon lamination involves bonding a thin layer of polytetrafluoroethylene (PTFE) film onto a substrate, enhancing surface properties like chemical resistance, non-stick characteristics, and temperature tolerance. This process typically uses heat and pressure to fuse the PTFE layer without altering the base material's structural integrity. Key methods include roll-to-roll lamination and hot press lamination, which ensure uniform coating and durability for applications in electronics, aerospace, and medical devices.

Material Properties: Encapsulation vs Lamination

Teflon encapsulation involves coating the material entirely with a durable, chemical-resistant layer that provides superior protection against corrosion, heat, and moisture. Teflon lamination, on the other hand, bonds a thin Teflon film to the substrate surface, offering excellent non-stick properties and moderate resistance to abrasion but less comprehensive shielding compared to encapsulation. Encapsulation delivers enhanced mechanical strength and long-term durability, while lamination prioritizes flexibility and lightweight characteristics.

Performance Comparison: Durability and Chemical Resistance

Teflon encapsulation offers superior durability by providing a robust, seamless protective layer that resists abrasion and harsh environmental conditions more effectively than Teflon lamination. Chemical resistance in Teflon encapsulation excels due to its complete coverage, preventing chemical permeation and degradation over time, whereas lamination may have weak points at seams or edges. In high-performance applications requiring maximum longevity and chemical inertness, Teflon encapsulation is often preferred over lamination for enhanced reliability.

Application Sectors: Where Encapsulation and Lamination Excel

Teflon encapsulation is ideal for electrical and electronic components, providing superior insulation and moisture resistance critical in aerospace and automotive industries. Teflon lamination excels in chemical processing and food packaging due to its non-stick surface and chemical inertness, enhancing durability and cleanliness. Both methods offer unique benefits tailored to specific sectors, with encapsulation focusing on protection and lamination emphasizing surface performance.

Cost Analysis: Teflon Encapsulation vs Lamination

Teflon encapsulation generally incurs higher costs due to complex application processes and material usage compared to Teflon lamination, which involves bonding thin Teflon films to substrates at lower expense. Encapsulation offers superior protective properties, justifying its premium price in high-performance industries, whereas lamination suits cost-sensitive applications with moderate durability requirements. Analyzing long-term operational savings against upfront costs is crucial for selecting between Teflon encapsulation and lamination.

Advantages of Teflon Encapsulation

Teflon encapsulation offers superior chemical resistance, providing an effective barrier against corrosive substances and extreme temperatures, making it ideal for harsh industrial environments. It ensures enhanced durability and electrical insulation by completely surrounding components, resulting in longer product lifespan and improved performance reliability. Unlike Teflon lamination, encapsulation provides seamless protection without delamination risks, ensuring consistent material integrity under mechanical stress.

Benefits of Teflon Lamination

Teflon lamination offers enhanced chemical resistance and superior durability compared to encapsulation, making it ideal for applications requiring prolonged exposure to harsh environments. The lamination process creates a seamless, uniform coating that improves surface smoothness and reduces friction, extending the lifespan of industrial components. This method also allows for greater flexibility in design and application, providing better heat resistance and electrical insulation properties.

Choosing the Right Solution: Encapsulation or Lamination?

Teflon encapsulation provides superior chemical resistance and moisture protection by completely surrounding the component, making it ideal for harsh environments requiring maximum durability. Teflon lamination offers a lightweight, flexible barrier suitable for applications needing thin, breathable layers without compromising non-stick properties. Selecting between encapsulation and lamination depends on the specific use case, where durability and environmental resistance favor encapsulation, while flexibility and reduced material thickness favor lamination.

Teflon Encapsulation vs Teflon Lamination Infographic

materialdif.com

materialdif.com