PFA and PTFE are both fluoropolymers used in Teflon coatings, but PFA offers superior flexibility and transparency compared to PTFE's higher chemical resistance and non-stick properties. PFA coatings cure at higher temperatures, creating a more durable and abrasion-resistant surface ideal for applications demanding toughness and clarity. PTFE remains the preferred choice for extreme temperature resistance and excellent lubricity, making it suitable for cookware and industrial equipment.

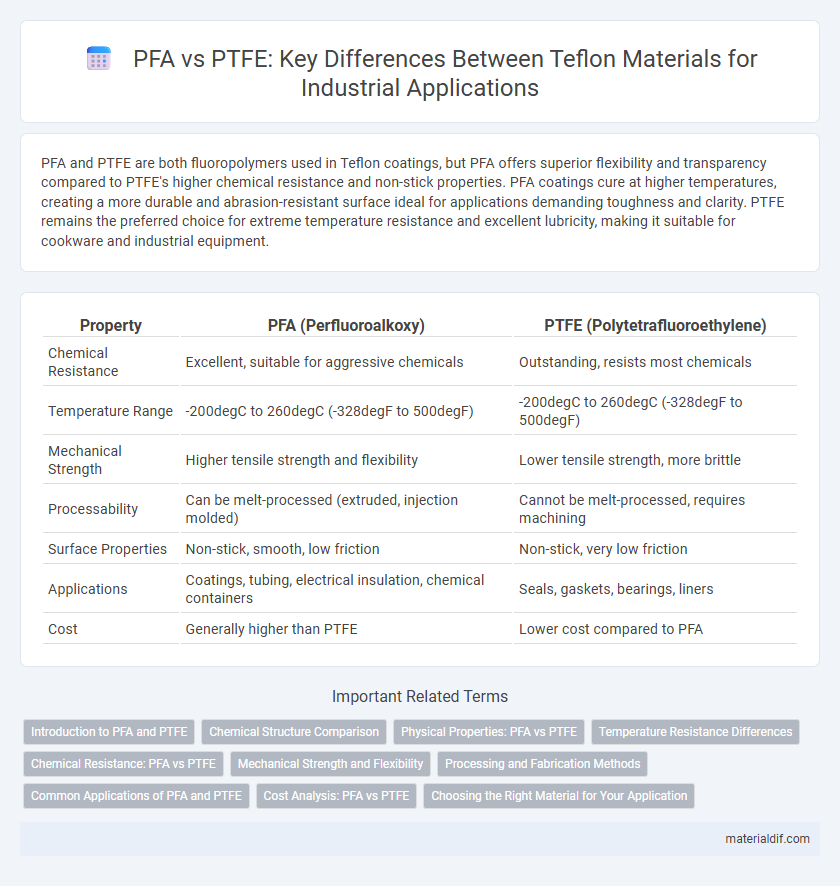

Table of Comparison

| Property | PFA (Perfluoroalkoxy) | PTFE (Polytetrafluoroethylene) |

|---|---|---|

| Chemical Resistance | Excellent, suitable for aggressive chemicals | Outstanding, resists most chemicals |

| Temperature Range | -200degC to 260degC (-328degF to 500degF) | -200degC to 260degC (-328degF to 500degF) |

| Mechanical Strength | Higher tensile strength and flexibility | Lower tensile strength, more brittle |

| Processability | Can be melt-processed (extruded, injection molded) | Cannot be melt-processed, requires machining |

| Surface Properties | Non-stick, smooth, low friction | Non-stick, very low friction |

| Applications | Coatings, tubing, electrical insulation, chemical containers | Seals, gaskets, bearings, liners |

| Cost | Generally higher than PTFE | Lower cost compared to PFA |

Introduction to PFA and PTFE

PFA (Perfluoroalkoxy) and PTFE (Polytetrafluoroethylene) are fluoropolymer materials known for their exceptional chemical resistance and non-stick properties. PTFE is widely recognized for its high melting point and excellent electrical insulation, making it ideal for diverse industrial applications, while PFA offers similar chemical resistance with enhanced flexibility and transparency. Both materials are used extensively in the chemical processing, electronics, and medical industries due to their durability and stability under extreme conditions.

Chemical Structure Comparison

PFA (Perfluoroalkoxy) and PTFE (Polytetrafluoroethylene) both consist of carbon-fluorine bonds, but PFA includes perfluoroalkoxy side chains containing oxygen atoms, which provide enhanced flexibility and processability compared to PTFE's simpler, linear chain of tetrafluoroethylene units. PTFE's fully fluorinated, linear polymer structure results in exceptional chemical resistance and thermal stability, while PFA's structure offers similar chemical inertness with improved melt flow properties for easier fabrication. The presence of ether linkages in PFA distinguishes its molecular architecture, making it more suitable for applications requiring complex shapes without sacrificing the inherent chemical resistance of fluoropolymers.

Physical Properties: PFA vs PTFE

PFA exhibits higher flexibility and impact resistance compared to PTFE, making it suitable for dynamic applications requiring durability. PTFE offers superior chemical resistance and a higher melting point, around 327degC, versus PFA's melting point near 305degC, which influences their thermal stability. Both polymers have low coefficients of friction, but PTFE's crystalline structure provides slightly better wear resistance than the more amorphous PFA.

Temperature Resistance Differences

PFA (Perfluoroalkoxy) and PTFE (Polytetrafluoroethylene) exhibit distinct temperature resistance properties critical for high-performance applications. PTFE can withstand continuous use temperatures up to approximately 260degC (500degF), while PFA tolerates slightly higher temperatures, maintaining stability up to 260-290degC (500-554degF). This makes PFA more suitable for environments requiring better thermal performance and resistance to thermal degradation.

Chemical Resistance: PFA vs PTFE

PFA (Perfluoroalkoxy) and PTFE (Polytetrafluoroethylene) both exhibit exceptional chemical resistance, making them ideal for handling aggressive chemicals and solvents. PFA offers slightly better resistance to strong oxidizers and higher temperature stability compared to PTFE, maintaining integrity in environments up to around 260degC. PTFE, known for its superior non-stick properties, remains highly resistant to most acids, bases, and organic solvents but can degrade under prolonged exposure to molten alkali metals or elemental fluorine.

Mechanical Strength and Flexibility

PFA (Perfluoroalkoxy) offers higher mechanical strength compared to PTFE (Polytetrafluoroethylene), making it more resistant to impact and stress while maintaining excellent chemical resistance. PTFE exhibits superior flexibility, allowing it to deform under stress without cracking, which is beneficial for applications requiring dynamic movement. The choice between PFA and PTFE depends on whether enhanced durability or elasticity is more critical for the specific industrial use.

Processing and Fabrication Methods

PFA (Perfluoroalkoxy) and PTFE (Polytetrafluoroethylene) differ significantly in processing and fabrication methods due to their molecular structures; PFA melts and can be processed using conventional thermoplastic methods like injection molding and extrusion, allowing for complex shapes and seamless coatings. PTFE, with its high melting viscosity, cannot be melted and reshaped by conventional thermoplastics techniques, requiring processes like ram extrusion, paste extrusion, or compression molding followed by sintering to achieve final forms. These differences impact production efficiency and product versatility in applications requiring chemical resistance and non-stick surfaces.

Common Applications of PFA and PTFE

PFA (Perfluoroalkoxy) is widely used in applications requiring chemical resistance and high purity, such as semiconductor manufacturing, chemical processing lines, and pharmaceutical equipment due to its excellent non-stick properties and ability to withstand aggressive chemicals. PTFE (Polytetrafluoroethylene) is common in industrial uses like gaskets, seals, linings, and cookware coatings, valued for its exceptional low friction, high temperature resistance, and electrical insulating properties. Both materials excel in environments demanding thermal stability and corrosion resistance, but PFA offers superior flexibility and transparency compared to the more rigid and opaque PTFE.

Cost Analysis: PFA vs PTFE

PFA (Perfluoroalkoxy) generally incurs higher costs compared to PTFE (Polytetrafluoroethylene) due to its superior melting properties and enhanced chemical resistance, making it suitable for more demanding applications. PTFE offers a more cost-effective solution with excellent chemical inertness, ideal for standard sealing, lining, and coating tasks. Evaluating total cost-effectiveness involves considering factors like temperature tolerance, mechanical strength, and lifespan, where PFA's advantages may justify its premium price in specialized industrial uses.

Choosing the Right Material for Your Application

PFA (perfluoroalkoxy) offers superior flexibility and chemical resistance at higher temperatures, making it ideal for applications requiring excellent thermal stability and corrosion resistance. PTFE (polytetrafluoroethylene) provides exceptional non-stick properties and low friction, suited for mechanical parts and coatings exposed to extreme chemical environments. Selecting between PFA and PTFE depends on specific operational demands like temperature tolerance, mechanical flexibility, and chemical exposure, ensuring optimal performance and durability.

PFA vs PTFE Infographic

materialdif.com

materialdif.com