Static-dissipative Teflon is designed to safely dissipate static electricity at a controlled rate, preventing sudden discharges that can damage sensitive electronic components. Conductive Teflon, on the other hand, provides a direct and low-resistance path for electrical current, making it ideal for grounding applications. Choosing between static-dissipative and conductive Teflon depends on the specific electrostatic discharge protection needs of the application.

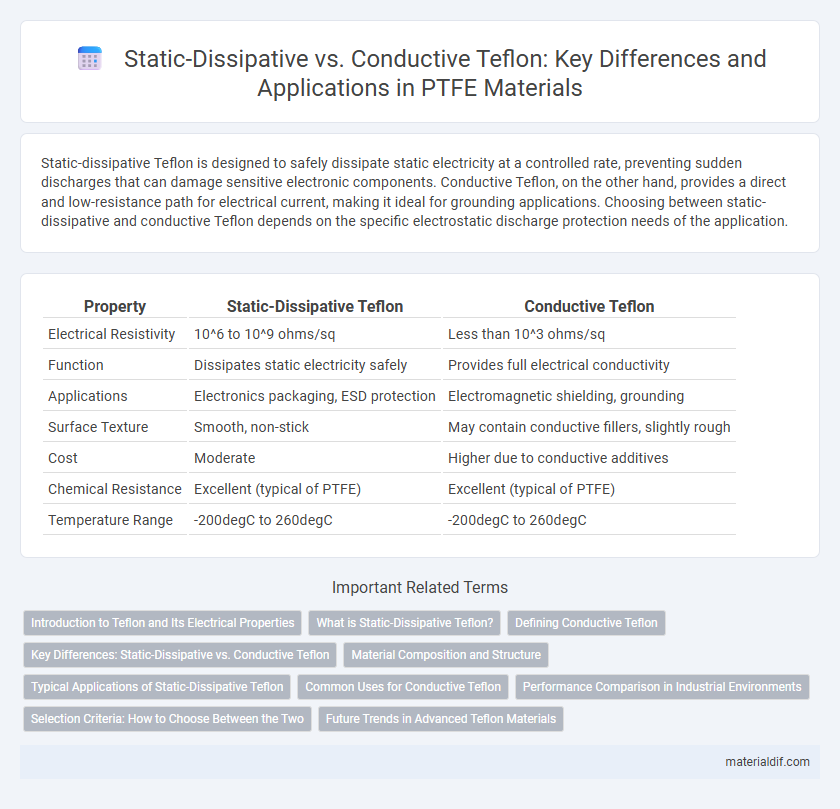

Table of Comparison

| Property | Static-Dissipative Teflon | Conductive Teflon |

|---|---|---|

| Electrical Resistivity | 10^6 to 10^9 ohms/sq | Less than 10^3 ohms/sq |

| Function | Dissipates static electricity safely | Provides full electrical conductivity |

| Applications | Electronics packaging, ESD protection | Electromagnetic shielding, grounding |

| Surface Texture | Smooth, non-stick | May contain conductive fillers, slightly rough |

| Cost | Moderate | Higher due to conductive additives |

| Chemical Resistance | Excellent (typical of PTFE) | Excellent (typical of PTFE) |

| Temperature Range | -200degC to 260degC | -200degC to 260degC |

Introduction to Teflon and Its Electrical Properties

Teflon, a fluoropolymer known for its chemical resistance and low friction, exhibits unique electrical properties varying between static-dissipative and conductive forms. Static-dissipative Teflon is engineered to reduce surface resistance by dispersing electrostatic charges safely, typically with surface resistivity ranging from 10^6 to 10^9 ohms/square. Conductive Teflon, infused with conductive fillers like carbon or metallic particles, achieves much lower resistivity below 10^5 ohms/square, enabling efficient grounding and shielding in sensitive electronic applications.

What is Static-Dissipative Teflon?

Static-dissipative Teflon is engineered to reduce the buildup of static electricity by allowing surface charges to slowly dissipate, preventing sudden electrostatic discharges. This type of Teflon maintains its inherent chemical resistance and non-stick properties while incorporating additives that enhance its electrical conductivity slightly without making it fully conductive. Static-dissipative Teflon is ideal for applications where controlled static discharge is crucial, such as in electronics manufacturing and cleanroom environments.

Defining Conductive Teflon

Conductive Teflon is engineered with carbon or metal fillers to create a continuous path for electrical conductivity, enabling efficient dissipation of static electricity. Unlike static-dissipative Teflon, which reduces surface resistivity but allows limited current flow, conductive Teflon exhibits much lower resistivity, typically below 10^3 ohms per square. This makes conductive Teflon essential in applications requiring rapid charge neutralization and protection against electrostatic discharge (ESD).

Key Differences: Static-Dissipative vs. Conductive Teflon

Static-dissipative Teflon features a surface resistivity typically ranging from 10^9 to 10^11 ohms per square, enabling it to safely dissipate static charges without generating sparks, making it ideal for applications requiring controlled electrostatic discharge. Conductive Teflon possesses significantly lower resistivity, often below 10^5 ohms per square, allowing for efficient electrical conduction and grounding in high-current environments. The key difference lies in their electrical conductivity levels, where static-dissipative Teflon prevents static buildup while conductive Teflon provides continuous electrical pathways.

Material Composition and Structure

Static-dissipative Teflon incorporates a controlled amount of conductive fillers such as carbon black or metal oxides embedded in the PTFE matrix, enabling surface resistivity typically in the range of 10^6 to 10^9 ohms/square which prevents static charge buildup. Conductive Teflon contains a higher concentration of conductive additives, often in the form of metal fibers or conductive polymers, creating interconnected pathways that drastically reduce resistivity to 10^3 to 10^5 ohms/square for effective electrical conduction. The structural difference lies in the dispersion and concentration of fillers, where static-dissipative Teflon maintains PTFE's inherent chemical inertness and slight conductivity, while conductive Teflon sacrifices some chemical resistance to achieve superior electrical conductivity through a more conductive filler network.

Typical Applications of Static-Dissipative Teflon

Static-dissipative Teflon is widely used in electronics manufacturing to prevent electrostatic discharge (ESD) damage during assembly and handling of sensitive components. Typical applications include cleanroom surfaces, semiconductor fabrication equipment, and protective linings for circuit boards. Its ability to safely dissipate static charges without compromising Teflon's chemical resistance makes it ideal for these environments.

Common Uses for Conductive Teflon

Conductive Teflon is commonly used in electronic enclosures, contacts, and connectors where reliable electrical conductivity is essential to prevent static buildup and ensure signal integrity. Its applications extend to aerospace and semiconductor manufacturing, providing electrostatic discharge (ESD) protection in sensitive environments. The material's combination of chemical resistance and conductivity makes it ideal for grounding components in corrosive or high-wear conditions.

Performance Comparison in Industrial Environments

Static-dissipative Teflon offers controlled electrical resistance, effectively preventing static charge buildup in sensitive industrial settings while maintaining the inherent chemical resistance and low friction of standard PTFE. Conductive Teflon, enhanced with conductive fillers like carbon or metal particles, provides superior conductivity for rapid charge dissipation, making it ideal for applications requiring efficient grounding under dynamic electrical loads. Performance-wise, static-dissipative Teflon excels in environments where moderate static control is sufficient without compromising mechanical properties, whereas conductive Teflon is preferable in high-voltage or electrostatic discharge-prone areas demanding immediate and reliable conductivity.

Selection Criteria: How to Choose Between the Two

Static-dissipative Teflon is ideal for environments requiring low surface resistivity to safely dissipate static charges without creating electrical conductivity, crucial in sensitive electronic manufacturing. Conductive Teflon, with significantly lower resistivity values, suits applications demanding effective grounding and shielding against electromagnetic interference. Selection depends on the specific electrostatic control needs, with static-dissipative grades preferred for preventing static buildup and conductive grades chosen for robust electrical grounding and EMI protection.

Future Trends in Advanced Teflon Materials

Static-dissipative Teflon materials are engineered to prevent static charge buildup by offering moderate electrical conductivity, ideal for sensitive electronic components, while conductive Teflon incorporates fillers such as carbon or metal particles to achieve higher conductivity levels for more demanding electrostatic discharge applications. Future trends in advanced Teflon materials emphasize enhancing electrical performance without compromising chemical resistance or thermal stability, with ongoing research into nano-fillers and hybrid composites to optimize conductivity and durability. Innovations in manufacturing processes aim to improve the uniform dispersion of conductive additives, resulting in materials that balance antistatic functionality and mechanical robustness for next-generation electronic and aerospace industries.

Static-dissipative Teflon vs Conductive Teflon Infographic

materialdif.com

materialdif.com