Teflon coating on pet products provides a durable, non-stick surface that repels dirt, water, and stains, enhancing cleanliness and longevity. Laminate, however, offers a protective layer that is typically thicker and more rigid, improving resistance to abrasion and moisture while preserving the material's original texture. Choosing between Teflon coating and laminate depends on the desired balance of flexibility, protection, and maintenance needs for pet accessories.

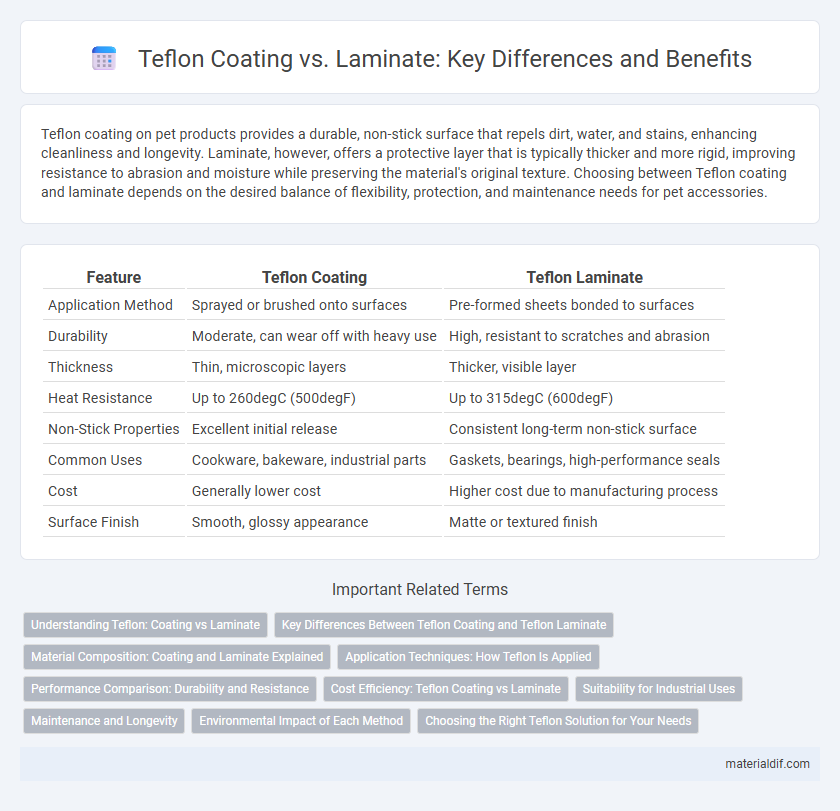

Table of Comparison

| Feature | Teflon Coating | Teflon Laminate |

|---|---|---|

| Application Method | Sprayed or brushed onto surfaces | Pre-formed sheets bonded to surfaces |

| Durability | Moderate, can wear off with heavy use | High, resistant to scratches and abrasion |

| Thickness | Thin, microscopic layers | Thicker, visible layer |

| Heat Resistance | Up to 260degC (500degF) | Up to 315degC (600degF) |

| Non-Stick Properties | Excellent initial release | Consistent long-term non-stick surface |

| Common Uses | Cookware, bakeware, industrial parts | Gaskets, bearings, high-performance seals |

| Cost | Generally lower cost | Higher cost due to manufacturing process |

| Surface Finish | Smooth, glossy appearance | Matte or textured finish |

Understanding Teflon: Coating vs Laminate

Teflon coatings provide a thin, non-stick layer that enhances surface resistance to heat and chemicals, making them ideal for cookware and industrial applications requiring friction reduction. Laminate involving Teflon integrates the polymer into multi-layered materials, offering superior durability, mechanical strength, and resistance to abrasion in demanding environments like aerospace and electronics. Understanding the distinction between Teflon as a coating versus a laminate is critical for selecting the appropriate application based on performance needs and environmental exposure.

Key Differences Between Teflon Coating and Teflon Laminate

Teflon coating involves applying a thin layer of polytetrafluoroethylene (PTFE) directly onto a surface, providing non-stick and anti-corrosion properties, while Teflon laminate consists of a PTFE film bonded to substrates for enhanced durability and chemical resistance. The key difference lies in application methods and performance: coatings offer smoother, flexible surfaces ideal for cookware and industrial parts, whereas laminates deliver thicker, more abrasion-resistant surfaces used in gaskets and seals. Both utilize PTFE's low friction and heat-resistant characteristics but cater to distinct functional requirements across various industries.

Material Composition: Coating and Laminate Explained

Teflon coating consists of a thin, non-stick layer of polytetrafluoroethylene (PTFE) applied directly onto surfaces, providing excellent heat resistance and chemical inertness. Laminate involves bonding a Teflon film onto substrates, combining the polymer's non-stick properties with enhanced mechanical strength and durability. The difference in material composition between coating and laminate affects performance characteristics such as scratch resistance, flexibility, and application methods.

Application Techniques: How Teflon Is Applied

Teflon is applied through two primary techniques: coating and lamination, each suited for different industrial applications. Coating involves spraying or dipping substrates with liquid Teflon dispersion, offering a seamless, non-stick surface ideal for cookware and fabric protection. Lamination bonds thin Teflon films to materials via heat and pressure, providing durable, heat-resistant layers used extensively in electrical insulation and aerospace components.

Performance Comparison: Durability and Resistance

Teflon coatings offer superior non-stick properties and chemical resistance compared to laminates, making them ideal for high-wear applications requiring frequent cleaning. Laminates provide enhanced structural strength and impact resistance but may degrade faster under abrasive conditions and exposure to harsh chemicals. The durability of Teflon coatings excels in environments demanding long-term resistance to corrosion, heat, and friction, while laminates perform better under physical stress and mechanical loads.

Cost Efficiency: Teflon Coating vs Laminate

Teflon coating offers superior cost efficiency compared to laminate due to its longer lifespan and resistance to wear, reducing maintenance and replacement expenses. While laminate typically incurs lower initial costs, it degrades faster under high temperatures and abrasive conditions, leading to higher long-term expenses. Choosing Teflon coating ensures durability and sustained performance, maximizing value over time in industrial and cookware applications.

Suitability for Industrial Uses

Teflon coating offers superior chemical resistance and non-stick properties ideal for industrial machinery exposed to corrosive substances and high temperatures. Laminate layers provide enhanced mechanical strength and impact resistance, making them suitable for protective surfaces in heavy-duty manufacturing environments. Industrial applications requiring frequent exposure to abrasive materials benefit more from laminate durability, while processes demanding low friction and easy cleaning favor Teflon coatings.

Maintenance and Longevity

Teflon coatings provide superior maintenance ease by resisting stains and requiring minimal cleaning compared to laminates, which can harbor dirt in their seams and surface textures. The longevity of Teflon coatings exceeds that of laminates due to their high resistance to abrasion, chemical exposure, and heat degradation. While laminates may delaminate or peel over time, Teflon maintains structural integrity and aesthetic appeal for extended periods, making it ideal for high-traffic or industrial applications.

Environmental Impact of Each Method

Teflon coating involves a chemical process that can release perfluorooctanoic acid (PFOA), contributing to environmental pollution and bioaccumulation in ecosystems. Laminate applications typically use adhesive layers with fewer harmful emissions but may generate more solid waste due to multi-material disposability challenges. The environmental footprint of Teflon coating often exceeds that of laminates because of persistent fluorinated compounds and complex wastewater treatment requirements.

Choosing the Right Teflon Solution for Your Needs

Choosing the right Teflon solution depends on the specific application requirements, with Teflon coating offering superior non-stick and chemical resistance properties for cookware and industrial parts. Teflon laminates provide enhanced durability, mechanical strength, and insulation, making them ideal for electrical and high-wear surfaces. Evaluating factors such as exposure to abrasion, temperature tolerance, and electrical insulation helps determine whether a Teflon coating or laminate best meets performance and longevity goals.

Coating vs Laminate Infographic

materialdif.com

materialdif.com