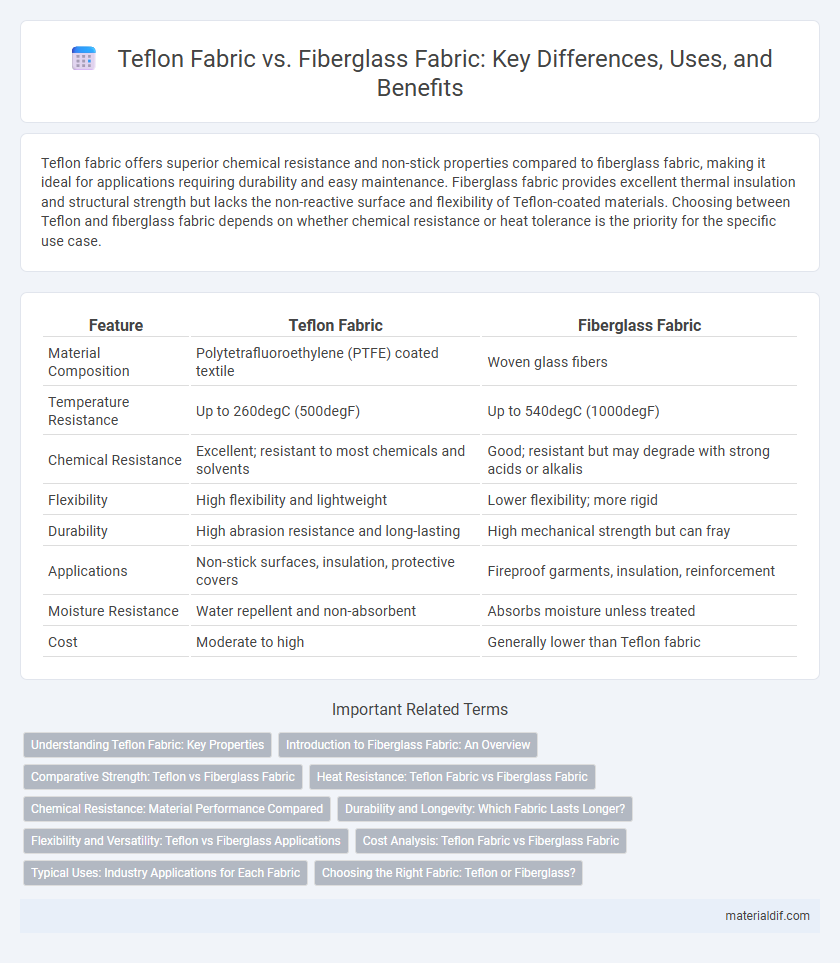

Teflon fabric offers superior chemical resistance and non-stick properties compared to fiberglass fabric, making it ideal for applications requiring durability and easy maintenance. Fiberglass fabric provides excellent thermal insulation and structural strength but lacks the non-reactive surface and flexibility of Teflon-coated materials. Choosing between Teflon and fiberglass fabric depends on whether chemical resistance or heat tolerance is the priority for the specific use case.

Table of Comparison

| Feature | Teflon Fabric | Fiberglass Fabric |

|---|---|---|

| Material Composition | Polytetrafluoroethylene (PTFE) coated textile | Woven glass fibers |

| Temperature Resistance | Up to 260degC (500degF) | Up to 540degC (1000degF) |

| Chemical Resistance | Excellent; resistant to most chemicals and solvents | Good; resistant but may degrade with strong acids or alkalis |

| Flexibility | High flexibility and lightweight | Lower flexibility; more rigid |

| Durability | High abrasion resistance and long-lasting | High mechanical strength but can fray |

| Applications | Non-stick surfaces, insulation, protective covers | Fireproof garments, insulation, reinforcement |

| Moisture Resistance | Water repellent and non-absorbent | Absorbs moisture unless treated |

| Cost | Moderate to high | Generally lower than Teflon fabric |

Understanding Teflon Fabric: Key Properties

Teflon fabric offers exceptional chemical resistance, non-stick properties, and high-temperature tolerance up to 500degF, making it ideal for industrial applications requiring durability and easy maintenance. In contrast, fiberglass fabric provides impressive strength and heat resistance but lacks the non-stick and chemical-resistant qualities of Teflon. Understanding these key properties helps in selecting the right material for applications such as protective clothing, conveyor belts, or insulation where specific performance characteristics are crucial.

Introduction to Fiberglass Fabric: An Overview

Fiberglass fabric consists of woven glass fibers that offer exceptional strength, heat resistance, and durability, making it ideal for high-temperature and industrial applications. Unlike Teflon fabric, fiberglass fabric provides superior structural integrity and resistance to flames, acids, and moisture, but lacks the non-stick and chemical inertness properties of Teflon. Commonly used in insulation, fire barriers, and composite materials, fiberglass fabric is a versatile solution where thermal stability and mechanical strength are prioritized.

Comparative Strength: Teflon vs Fiberglass Fabric

Teflon fabric exhibits superior chemical resistance and UV stability compared to fiberglass fabric, making it ideal for harsh environmental conditions. Fiberglass fabric generally offers higher tensile strength and better heat resistance, which suits applications involving extreme temperatures. Overall, the choice between Teflon and fiberglass fabrics depends on specific strength requirements and exposure conditions, with Teflon excelling in durability under corrosive environments and fiberglass in mechanical resilience.

Heat Resistance: Teflon Fabric vs Fiberglass Fabric

Teflon fabric exhibits superior heat resistance, withstanding continuous temperatures up to 500degF (260degC) without degradation, making it ideal for high-temperature applications. Fiberglass fabric can endure higher temperatures, often up to 1000degF (538degC), but lacks the chemical and UV resistance properties of Teflon. This combination of heat resilience and chemical inertness makes Teflon fabric especially valuable in environments requiring both thermal and chemical durability.

Chemical Resistance: Material Performance Compared

Teflon fabric exhibits superior chemical resistance compared to fiberglass fabric, offering enhanced durability against acids, bases, and solvents in harsh environments. The polytetrafluoroethylene (PTFE) coating on Teflon fabric provides exceptional non-reactive properties, preventing degradation and maintaining integrity under exposure to aggressive chemicals. Fiberglass fabric, while strong and heat-resistant, is more susceptible to chemical attack, especially from alkaline substances and strong acids, limiting its application in highly corrosive settings.

Durability and Longevity: Which Fabric Lasts Longer?

Teflon fabric exhibits exceptional durability due to its non-reactive and stain-resistant properties, allowing it to withstand harsh environmental conditions without degrading. Fiberglass fabric offers high tensile strength and resistance to heat and chemicals, yet it is more prone to wear and tear over time compared to Teflon-coated materials. Overall, Teflon fabric generally lasts longer in outdoor and industrial applications where exposure to weather and contaminants is frequent.

Flexibility and Versatility: Teflon vs Fiberglass Applications

Teflon fabric offers superior flexibility compared to fiberglass fabric, making it ideal for applications requiring frequent bending and movement, such as protective clothing and flexible gaskets. Fiberglass fabric excels in heat resistance and structural integrity but tends to be stiffer, limiting its use in dynamic environments. The versatility of Teflon fabric extends to chemical resistance and weatherproofing, broadening its application range across industrial, automotive, and aerospace sectors.

Cost Analysis: Teflon Fabric vs Fiberglass Fabric

Teflon fabric typically costs more upfront compared to fiberglass fabric due to its advanced PTFE coating and superior chemical resistance. However, Teflon's extended lifespan and low maintenance requirements can result in lower total cost of ownership over time. Fiberglass fabric, while cheaper initially, may incur higher replacement and upkeep costs, impacting overall cost efficiency in long-term industrial applications.

Typical Uses: Industry Applications for Each Fabric

Teflon fabric is widely used in chemical processing and food manufacturing industries due to its non-stick, heat-resistant, and corrosion-resistant properties, making it ideal for conveyor belts, gaskets, and protective clothing. Fiberglass fabric is favored in aerospace, automotive, and construction sectors for insulation, reinforcement, and fireproofing applications owing to its high tensile strength and thermal stability. Both materials serve critical roles in industrial environments where durability and resistance to extreme conditions are essential.

Choosing the Right Fabric: Teflon or Fiberglass?

Teflon fabric offers superior chemical resistance and non-stick properties, making it ideal for applications requiring easy cleaning and durability in harsh environments. Fiberglass fabric provides excellent heat resistance and mechanical strength, suited for high-temperature insulation and structural reinforcement. Selecting the right fabric depends on prioritizing either Teflon's chemical inertness and low friction or fiberglass's thermal stability and tensile strength for your specific project needs.

Teflon Fabric vs Fiberglass Fabric Infographic

materialdif.com

materialdif.com