Teflon AF and Teflon FEP are fluoropolymer variants widely used in applications requiring chemical resistance and non-stick properties. Teflon AF offers superior optical transparency and higher temperature resistance, making it ideal for specialty coatings and electronic components, whereas Teflon FEP provides excellent flexibility and ease of processing for tubing and wire insulation. Choosing between Teflon AF and FEP depends on the specific mechanical and thermal requirements of the pet product application.

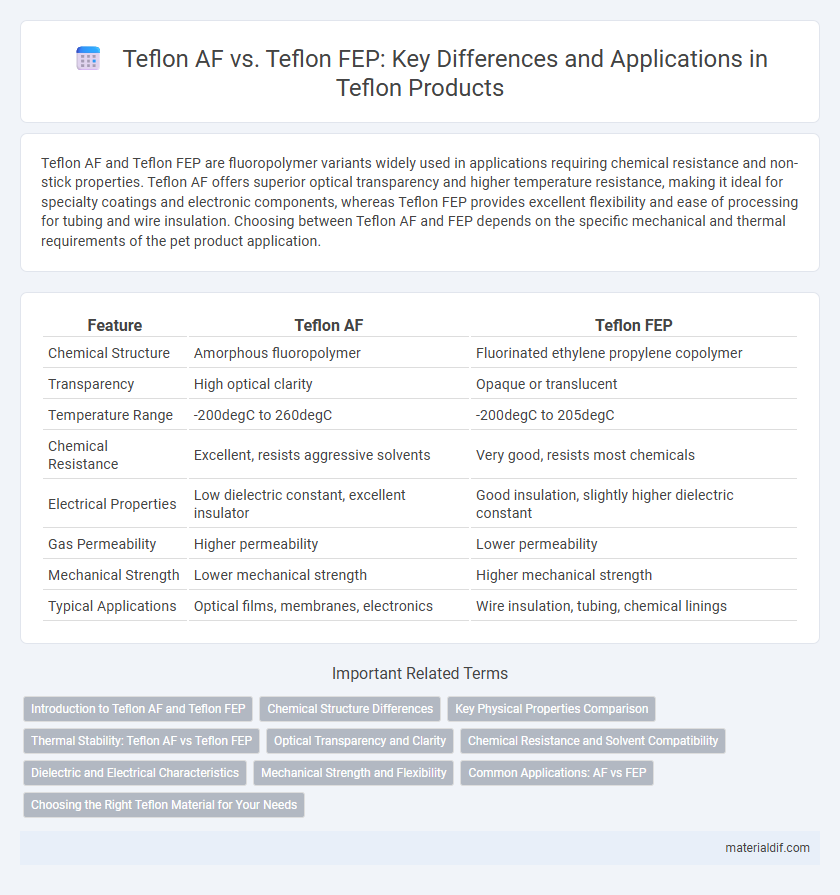

Table of Comparison

| Feature | Teflon AF | Teflon FEP |

|---|---|---|

| Chemical Structure | Amorphous fluoropolymer | Fluorinated ethylene propylene copolymer |

| Transparency | High optical clarity | Opaque or translucent |

| Temperature Range | -200degC to 260degC | -200degC to 205degC |

| Chemical Resistance | Excellent, resists aggressive solvents | Very good, resists most chemicals |

| Electrical Properties | Low dielectric constant, excellent insulator | Good insulation, slightly higher dielectric constant |

| Gas Permeability | Higher permeability | Lower permeability |

| Mechanical Strength | Lower mechanical strength | Higher mechanical strength |

| Typical Applications | Optical films, membranes, electronics | Wire insulation, tubing, chemical linings |

Introduction to Teflon AF and Teflon FEP

Teflon AF (amorphous fluoropolymer) is a specialized fluoropolymer known for its exceptional optical transparency and gas barrier properties, making it ideal for advanced microelectronics and membrane applications. Teflon FEP (fluorinated ethylene propylene) offers excellent chemical resistance and a low coefficient of friction, suited for flexible tubing, wire insulation, and chemical processing equipment. Both materials provide unique benefits in high-performance environments, with Teflon AF emphasizing clarity and permeability control, while Teflon FEP focuses on durability and flexibility.

Chemical Structure Differences

Teflon AF is an amorphous fluoropolymer composed of tetrafluoroethylene (TFE) and perfluoro(alkyl vinyl ether) (PAVE) units, resulting in a non-crystalline, transparent structure with enhanced gas permeability. Teflon FEP, on the other hand, is a copolymer of tetrafluoroethylene and hexafluoropropylene, featuring a semi-crystalline structure that provides high chemical resistance and excellent electrical insulation. The key chemical difference lies in Teflon AF's amorphous arrangement disrupting crystallinity, while Teflon FEP maintains crystallinity due to its fluorinated propylene comonomer.

Key Physical Properties Comparison

Teflon AF exhibits exceptional optical clarity with a refractive index around 1.30, significantly lower than Teflon FEP's 1.34, making it ideal for optical applications requiring low light scattering. Teflon FEP demonstrates better mechanical strength and flexibility, with a tensile strength near 20 MPa compared to Teflon AF's lower value, which limits its use in high-stress environments. Both materials offer excellent chemical resistance and high thermal stability, but Teflon AF maintains superior gas permeability performance, beneficial for membrane and barrier technologies.

Thermal Stability: Teflon AF vs Teflon FEP

Teflon AF exhibits superior thermal stability with a higher glass transition temperature around 240degC compared to Teflon FEP, which has a melting point near 260degC but lower thermal resistance under prolonged exposure. Teflon AF maintains mechanical and chemical properties at elevated temperatures, making it suitable for high-performance applications requiring thermal endurance. In contrast, Teflon FEP offers excellent melting behavior but can degrade more quickly under sustained thermal stress.

Optical Transparency and Clarity

Teflon AF exhibits superior optical transparency and clarity compared to Teflon FEP, with light transmittance exceeding 95% in the visible spectrum, making it ideal for high-performance optical applications. Teflon FEP, while possessing excellent chemical resistance, generally shows lower transparency due to its semi-crystalline structure, resulting in increased light scattering and reduced clarity. The amorphous nature of Teflon AF allows for minimal haze and enhanced clarity, crucial for precise optical components and lenses.

Chemical Resistance and Solvent Compatibility

Teflon AF exhibits superior chemical resistance compared to Teflon FEP, making it highly effective against aggressive solvents such as hydrocarbons, aromatic compounds, and aggressive acids. Teflon FEP maintains excellent solvent compatibility with a broad range of chemicals, including strong oxidizers and alkalis, but is less resistant to swelling and permeation under harsh chemical exposure. The unique amorphous fluoropolymer structure of Teflon AF provides enhanced barrier properties, resulting in lower solvent absorption and improved durability in extreme chemical environments.

Dielectric and Electrical Characteristics

Teflon AF exhibits superior dielectric properties with a dielectric constant around 1.8, significantly lower than Teflon FEP's dielectric constant of approximately 2.1, resulting in better insulating performance and reduced signal loss. Its electrical breakdown strength surpasses that of Teflon FEP, making it ideal for high-frequency and high-voltage applications where enhanced insulation reliability is critical. The amorphous structure of Teflon AF also contributes to lower dielectric loss tangent values, further optimizing electrical efficiency compared to the semi-crystalline nature of Teflon FEP.

Mechanical Strength and Flexibility

Teflon AF exhibits lower mechanical strength but significantly higher flexibility compared to Teflon FEP, making it ideal for applications requiring elastic deformation and optical clarity. Teflon FEP offers superior mechanical durability and chemical resistance, suited for environments subjected to mechanical stress and abrasion. The choice between Teflon AF and Teflon FEP depends on balancing flexibility needs with structural robustness in high-performance polymer applications.

Common Applications: AF vs FEP

Teflon AF is widely used in optical fibers, microelectronics, and gas separation membranes due to its exceptional clarity and low refractive index, enabling precise signal transmission and chemical resistance. Teflon FEP is commonly applied in wire and cable insulation, chemical processing equipment, and cookware coatings, offering excellent chemical resistance and flexibility at a lower cost. The choice between Teflon AF and Teflon FEP depends on the specific need for optical clarity or mechanical durability in the application.

Choosing the Right Teflon Material for Your Needs

Teflon AF offers superior optical clarity and low refractive index, making it ideal for advanced electronics and optical applications requiring high transparency and chemical resistance. Teflon FEP provides excellent flexibility, UV resistance, and ease of fabrication, suitable for wire insulation and tubing in harsh environments. Choosing between Teflon AF and FEP depends on the specific requirements for optical performance versus mechanical flexibility and processing needs.

Teflon AF vs Teflon FEP Infographic

materialdif.com

materialdif.com