Filled PTFE offers enhanced mechanical strength, improved wear resistance, and reduced friction compared to unfilled PTFE, making it suitable for demanding pet-related applications such as high-durability pet collars and grooming tools. Unfilled PTFE provides excellent chemical resistance and low friction but tends to be softer and less resistant to deformation under stress. Selecting between filled and unfilled PTFE depends on balancing performance requirements against cost and flexibility in pet product design.

Table of Comparison

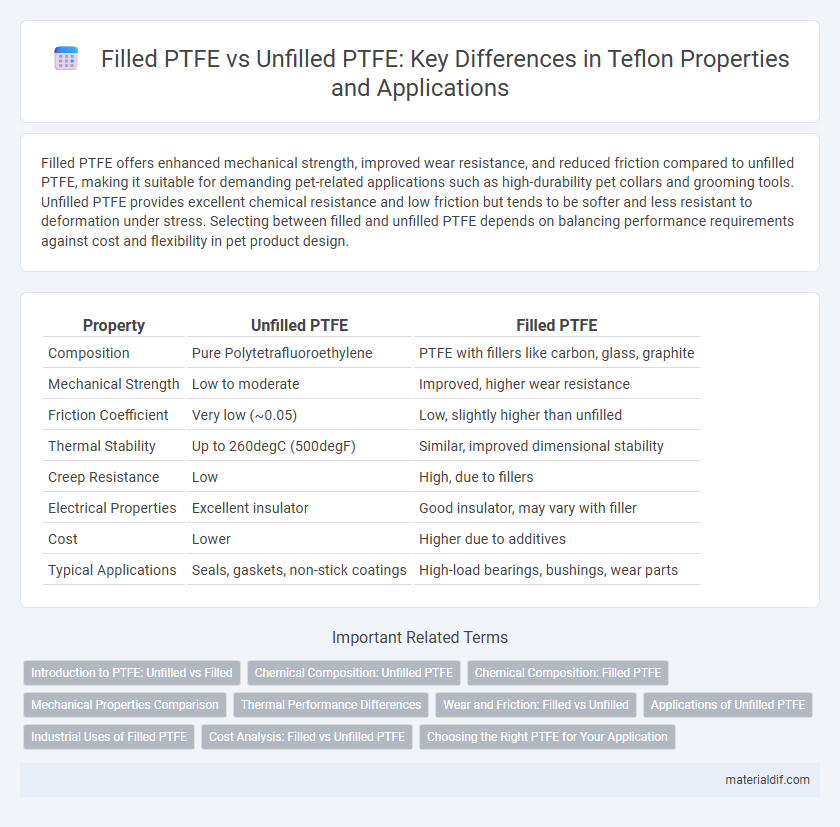

| Property | Unfilled PTFE | Filled PTFE |

|---|---|---|

| Composition | Pure Polytetrafluoroethylene | PTFE with fillers like carbon, glass, graphite |

| Mechanical Strength | Low to moderate | Improved, higher wear resistance |

| Friction Coefficient | Very low (~0.05) | Low, slightly higher than unfilled |

| Thermal Stability | Up to 260degC (500degF) | Similar, improved dimensional stability |

| Creep Resistance | Low | High, due to fillers |

| Electrical Properties | Excellent insulator | Good insulator, may vary with filler |

| Cost | Lower | Higher due to additives |

| Typical Applications | Seals, gaskets, non-stick coatings | High-load bearings, bushings, wear parts |

Introduction to PTFE: Unfilled vs Filled

PTFE, or polytetrafluoroethylene, is a versatile fluoropolymer known for its low friction and high chemical resistance, existing in unfilled and filled forms. Unfilled PTFE offers excellent non-stick properties and electrical insulation, while filled PTFE incorporates materials such as glass, carbon, or graphite to enhance mechanical strength, wear resistance, and thermal conductivity. Choosing between unfilled and filled PTFE depends on specific application requirements including load capacity, friction, and environmental conditions.

Chemical Composition: Unfilled PTFE

Unfilled PTFE consists of a pure polymer composed solely of tetrafluoroethylene monomers, resulting in a homogenous chemical structure with a molecular formula of (C2F4)n. This chemical composition imparts high chemical resistance, low friction, and excellent thermal stability. Unlike filled PTFE, unfilled PTFE lacks additives or fillers, which can influence mechanical strength and wear resistance but maintains superior purity and chemical inertness.

Chemical Composition: Filled PTFE

Filled PTFE contains polytetrafluoroethylene combined with reinforcing materials such as glass fibers, carbon, graphite, or bronze to enhance mechanical strength, wear resistance, and thermal stability. These fillers improve the chemical composition by reducing the coefficient of friction and increasing resistance to deformation under stress, while maintaining PTFE's inherent chemical inertness. The selection of specific fillers tailors the composite for specialized applications requiring improved durability and performance compared to unfilled PTFE.

Mechanical Properties Comparison

Filled PTFE exhibits significantly enhanced mechanical properties compared to unfilled PTFE, including increased tensile strength, improved wear resistance, and higher compressive strength. Common fillers such as glass, carbon, or bronze fibers reinforce the polymer matrix, reducing deformation and enhancing dimensional stability under stress. Unfilled PTFE, while possessing excellent chemical resistance and low friction, tends to have lower mechanical durability and is more prone to creep and cold flow under mechanical loads.

Thermal Performance Differences

Filled PTFE contains additives such as glass fibers, carbon, or graphite that significantly enhance its thermal conductivity and reduce thermal expansion compared to unfilled PTFE, enabling better heat dissipation and dimensional stability under high temperatures. Unfilled PTFE exhibits low thermal conductivity (around 0.25 W/m*K) and higher thermal expansion, limiting its performance in heat-sensitive applications. The improved thermal performance of filled PTFE makes it ideal for components subjected to continuous thermal cycling and higher operating temperatures exceeding 260degC.

Wear and Friction: Filled vs Unfilled

Filled PTFE typically exhibits significantly lower wear rates and enhanced friction performance compared to unfilled PTFE due to the incorporation of reinforcing fillers like glass, carbon, or graphite. These fillers increase hardness and structural integrity, resulting in improved abrasion resistance and reduced coefficient of friction under dynamic conditions. Unfilled PTFE, while offering excellent chemical resistance, tends to have higher wear and friction levels, making it less suitable for applications demanding enhanced durability and mechanical performance.

Applications of Unfilled PTFE

Unfilled PTFE exhibits exceptional chemical resistance and low friction, making it ideal for applications in the chemical processing industry, such as lining pipes and tanks. Its high temperature tolerance and non-stick properties are crucial for use in food processing equipment and pharmaceutical manufacturing. Unfilled PTFE also serves effectively in electrical insulation due to its excellent dielectric properties and stability.

Industrial Uses of Filled PTFE

Filled PTFE exhibits enhanced mechanical properties and wear resistance compared to unfilled PTFE, making it ideal for industrial applications such as seals, bearings, and valve seats. Common fillers like glass, carbon, and graphite improve thermal conductivity and reduce friction, extending the lifespan of components in chemical processing, automotive, and aerospace industries. These improvements enable filled PTFE to perform reliably under high temperatures, pressure, and aggressive chemical environments.

Cost Analysis: Filled vs Unfilled PTFE

Filled PTFE typically offers enhanced mechanical properties and wear resistance compared to unfilled PTFE, but these benefits come at a higher material cost due to the incorporation of fillers such as glass, carbon, or graphite. Unfilled PTFE remains a cost-effective choice for applications where superior strength is not critical, maintaining excellent chemical resistance and low friction at a lower price point. The cost analysis between filled and unfilled PTFE should balance performance requirements against budget constraints, as filled PTFE can reduce maintenance and replacement expenses despite its initial higher cost.

Choosing the Right PTFE for Your Application

Filled PTFE incorporates additives like glass, carbon, or bronze to enhance wear resistance, thermal stability, and mechanical strength, making it ideal for high-load or abrasive environments. Unfilled PTFE offers superior chemical inertness, low friction, and excellent electrical insulation, suited for applications requiring maximum purity and low friction performance. Selecting the right PTFE depends on balancing mechanical demands, chemical compatibility, and frictional properties specific to your application's operating conditions.

filled PTFE vs unfilled PTFE Infographic

materialdif.com

materialdif.com