Teflon FEP offers excellent chemical resistance and a lower melting point, making it ideal for applications requiring flexibility and ease of processing. Teflon PFA provides superior thermal stability and higher purity, suitable for demanding environments involving high temperatures and aggressive chemicals. Both materials excel in non-stick properties and electrical insulation, but the choice depends on specific thermal and mechanical requirements.

Table of Comparison

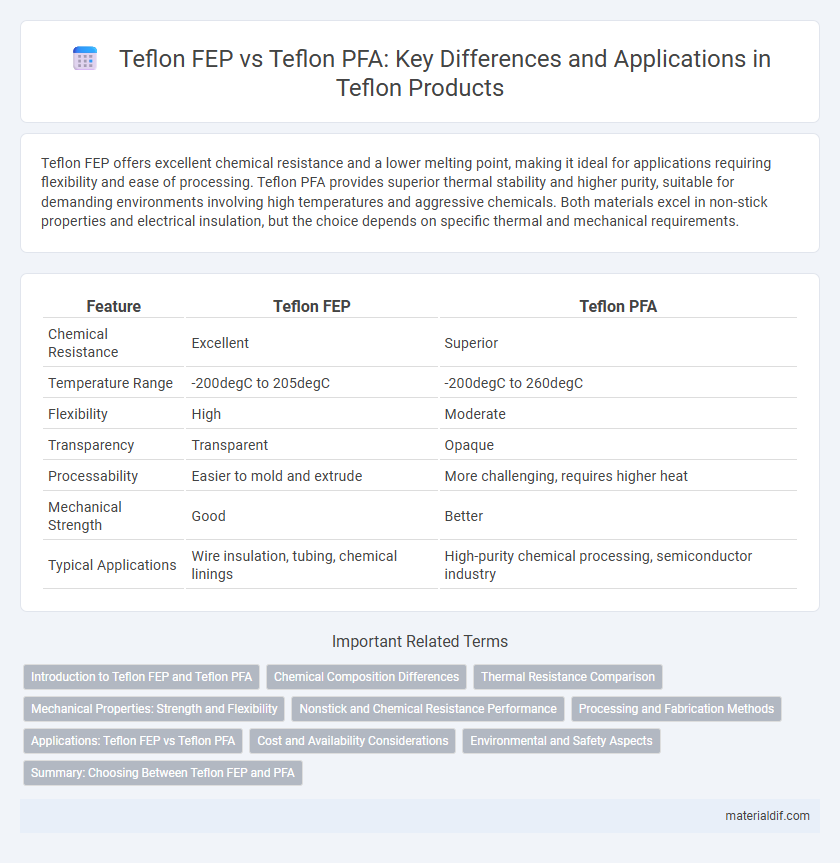

| Feature | Teflon FEP | Teflon PFA |

|---|---|---|

| Chemical Resistance | Excellent | Superior |

| Temperature Range | -200degC to 205degC | -200degC to 260degC |

| Flexibility | High | Moderate |

| Transparency | Transparent | Opaque |

| Processability | Easier to mold and extrude | More challenging, requires higher heat |

| Mechanical Strength | Good | Better |

| Typical Applications | Wire insulation, tubing, chemical linings | High-purity chemical processing, semiconductor industry |

Introduction to Teflon FEP and Teflon PFA

Teflon FEP (fluorinated ethylene propylene) and Teflon PFA (perfluoroalkoxy alkane) are types of fluoropolymers known for exceptional chemical resistance and non-stick properties. FEP offers superior electrical insulation and flexibility, making it ideal for lightweight, heat-resistant applications. PFA provides enhanced chemical resistance and can withstand higher temperatures, suitable for demanding industrial environments requiring durability and purity.

Chemical Composition Differences

Teflon FEP (fluorinated ethylene propylene) consists of a copolymer of hexafluoropropylene and tetrafluoroethylene, offering a more flexible and transparent polymer structure. Teflon PFA (perfluoroalkoxy alkane) contains perfluoroalkoxy side chains attached to the polymer backbone, enhancing chemical resistance and melt processability. These variations in chemical composition result in differing thermal stability and mechanical properties between FEP and PFA coatings.

Thermal Resistance Comparison

Teflon FEP (fluorinated ethylene propylene) exhibits a maximum continuous use temperature of approximately 200degC, while Teflon PFA (perfluoroalkoxy alkane) withstands higher temperatures up to 260degC. PFA demonstrates superior thermal resistance, maintaining physical and chemical properties at elevated temperatures where FEP softens or degrades. This difference makes PFA preferable for high-temperature applications requiring prolonged exposure without compromising material integrity.

Mechanical Properties: Strength and Flexibility

Teflon FEP exhibits higher flexibility and excellent elongation properties, making it suitable for applications requiring bending and shaping without cracking. Teflon PFA offers superior mechanical strength and resistance to stress, enabling it to withstand higher pressure and mechanical strain. Both fluoropolymers provide excellent chemical resistance, but Teflon PFA's enhanced mechanical robustness often makes it preferable for demanding industrial uses.

Nonstick and Chemical Resistance Performance

Teflon FEP offers superior nonstick properties with excellent chemical resistance, making it ideal for applications requiring frequent chemical exposure and easy material release. Teflon PFA enhances performance by combining exceptional nonstick capabilities with higher temperature tolerance and greater chemical inertness, suitable for harsh environments and aggressive chemicals. Both materials provide outstanding durability, but PFA generally outperforms FEP in long-term chemical resistance and thermal stability.

Processing and Fabrication Methods

Teflon FEP (fluorinated ethylene propylene) and Teflon PFA (perfluoroalkoxy alkane) differ significantly in processing and fabrication methods due to their molecular structures; FEP melts and flows more readily, allowing easier extrusion and injection molding, while PFA's higher thermal stability demands higher processing temperatures and is better suited for complex molding and coating applications. The semi-crystalline nature of FEP provides greater melt flow properties, facilitating faster production cycles in film and tubing manufacturing, whereas PFA offers superior chemical resistance and weldability, important in high-purity industrial components. Understanding these differences optimizes manufacturing efficiency and material performance in applications requiring precise thermal and chemical resilience.

Applications: Teflon FEP vs Teflon PFA

Teflon FEP offers excellent chemical resistance and flexibility, making it ideal for applications like wire insulation, tubing, and protective coatings in the chemical and food processing industries. Teflon PFA provides superior high-temperature resistance and mechanical strength, commonly used in semiconductor manufacturing, pharmaceutical equipment, and fluid handling systems requiring stringent purity standards. Both materials excel in non-stick properties and corrosion resistance, but PFA's enhanced thermal stability makes it preferable for more demanding thermal environments.

Cost and Availability Considerations

Teflon FEP generally offers a more cost-effective solution compared to Teflon PFA, due to its easier manufacturing process and higher availability in various markets. PFA, although more expensive, provides superior chemical resistance and temperature tolerance, making it a premium choice for specialized applications. Availability of FEP is widespread, supporting diverse industries with standard lead times, while PFA demand often leads to longer procurement cycles and higher price volatility.

Environmental and Safety Aspects

Teflon FEP (fluorinated ethylene propylene) offers superior chemical resistance and lower environmental impact due to its easier recyclability compared to Teflon PFA (perfluoroalkoxy alkane). Teflon PFA exhibits higher heat resistance but poses greater challenges in disposal because of its more complex molecular structure, raising concerns about persistent environmental pollution. Both materials require careful handling to minimize emissions of harmful perfluorinated compounds during manufacturing and disposal, emphasizing the need for stringent safety protocols.

Summary: Choosing Between Teflon FEP and PFA

Teflon FEP offers excellent chemical resistance, flexibility, and lower cost, making it ideal for applications requiring transparency and moderate mechanical strength. Teflon PFA provides superior thermal stability, higher mechanical strength, and improved resistance to harsh chemicals, suitable for demanding environments like semiconductor manufacturing. Selecting between Teflon FEP and PFA depends on specific requirements for temperature tolerance, chemical exposure, and budget constraints.

Teflon FEP vs Teflon PFA Infographic

materialdif.com

materialdif.com