Teflon lined pet collars provide enhanced durability and resistance to moisture, making them ideal for pets prone to outdoor activities or swimming. Unlined collars, while typically lighter and more flexible, may wear out faster and lack the waterproof qualities of lined options. Choosing between Teflon lined vs unlined depends on the pet's lifestyle and the owner's preference for longevity versus comfort.

Table of Comparison

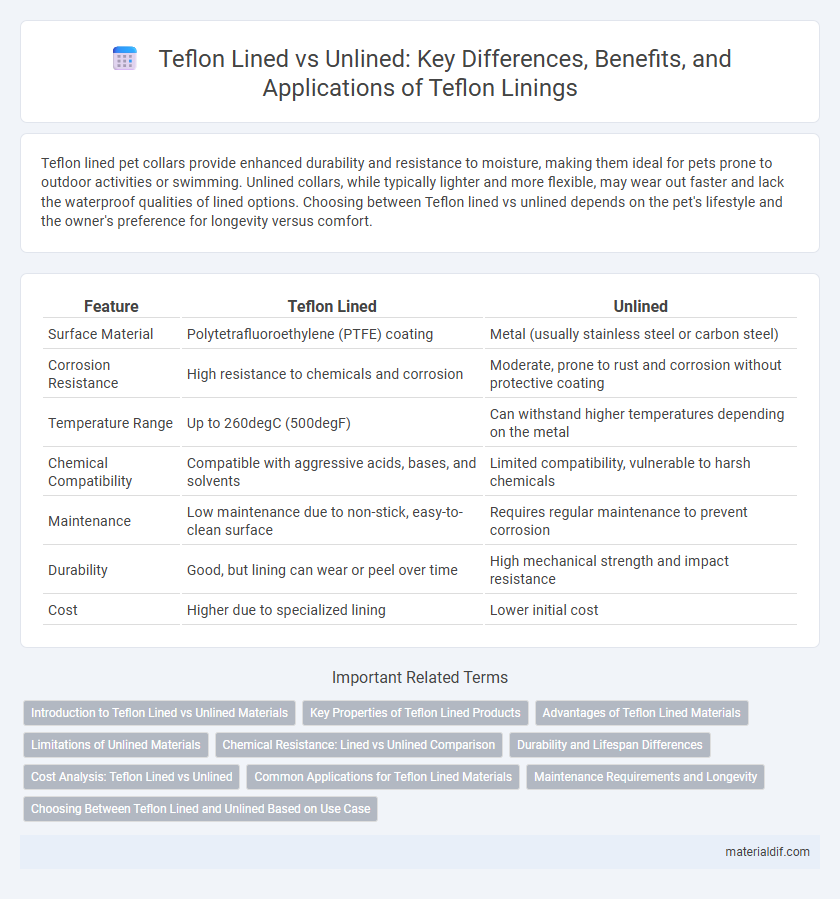

| Feature | Teflon Lined | Unlined |

|---|---|---|

| Surface Material | Polytetrafluoroethylene (PTFE) coating | Metal (usually stainless steel or carbon steel) |

| Corrosion Resistance | High resistance to chemicals and corrosion | Moderate, prone to rust and corrosion without protective coating |

| Temperature Range | Up to 260degC (500degF) | Can withstand higher temperatures depending on the metal |

| Chemical Compatibility | Compatible with aggressive acids, bases, and solvents | Limited compatibility, vulnerable to harsh chemicals |

| Maintenance | Low maintenance due to non-stick, easy-to-clean surface | Requires regular maintenance to prevent corrosion |

| Durability | Good, but lining can wear or peel over time | High mechanical strength and impact resistance |

| Cost | Higher due to specialized lining | Lower initial cost |

Introduction to Teflon Lined vs Unlined Materials

Teflon lined materials feature a non-reactive, chemically resistant fluoropolymer coating that protects the underlying surface from corrosion and contamination in industrial applications. Unlined materials lack this protective layer, making them more susceptible to chemical attack and wear but often more cost-effective and suitable for less aggressive environments. Selecting between Teflon lined and unlined materials depends on factors such as chemical compatibility, temperature tolerance, and operational longevity requirements.

Key Properties of Teflon Lined Products

Teflon lined products offer exceptional chemical resistance, non-stick properties, and high-temperature tolerance up to 260degC, making them ideal for corrosive environments and easy cleaning. The lined surfaces significantly reduce friction and prevent material buildup, enhancing flow efficiency and durability in industrial applications. Compared to unlined options, Teflon lining provides superior corrosion protection, extended equipment lifespan, and improved process reliability.

Advantages of Teflon Lined Materials

Teflon lined materials offer superior chemical resistance and non-stick properties compared to unlined alternatives, reducing corrosion and contamination risks in industrial applications. The lined surfaces facilitate easier cleaning and maintenance, extending the lifespan of equipment in harsh environments. Enhanced thermal stability and reduced friction of Teflon linings improve overall process efficiency and safety in chemical processing and manufacturing industries.

Limitations of Unlined Materials

Unlined materials lack the chemical resistance and non-stick properties of Teflon-lined surfaces, making them prone to corrosion and contamination in harsh environments. They are unsuitable for applications involving aggressive chemicals or high temperatures where durability and performance are critical. This limitation often leads to decreased operational efficiency and increased maintenance costs.

Chemical Resistance: Lined vs Unlined Comparison

Teflon-lined equipment offers superior chemical resistance compared to unlined options, effectively protecting against strong acids, bases, and solvents without corrosion. Unlined materials, such as stainless steel or carbon steel, may react with aggressive chemicals, leading to degradation and contamination risks. Selecting Teflon lining ensures enhanced durability and longer service life in highly corrosive environments, making it ideal for chemical processing applications.

Durability and Lifespan Differences

Teflon-lined cookware offers enhanced durability due to its non-reactive, scratch-resistant surface that reduces wear and extends lifespan compared to unlined metals prone to corrosion and degradation. The PTFE coating in Teflon-lined products prevents food from sticking and protects underlying materials from acidic or abrasive substances, significantly increasing long-term usability. Unlined cookware, while often more affordable, typically shows faster signs of deterioration and requires more maintenance to preserve cooking performance and safety.

Cost Analysis: Teflon Lined vs Unlined

Teflon lined equipment typically incurs higher initial costs due to the specialized lining process and material expenses, but offers superior chemical resistance and longevity, reducing maintenance and replacement costs over time. Unlined alternatives are cheaper upfront but may require frequent repairs or replacements when exposed to corrosive substances, increasing long-term expenditure. Evaluating total cost of ownership reveals that Teflon lined options often provide better value in aggressive chemical environments despite their higher initial investment.

Common Applications for Teflon Lined Materials

Teflon lined materials are widely used in chemical processing industries for their exceptional corrosion resistance and non-stick properties, making them ideal for lining pipes, tanks, and reactors handling aggressive acids and solvents. These linings provide superior protection against harsh chemicals, abrasion, and high temperatures, extending equipment lifespan and reducing maintenance costs. Common applications include pharmaceutical manufacturing, food processing, and semiconductor production, where contamination control and chemical inertness are critical.

Maintenance Requirements and Longevity

Teflon lined surfaces require minimal maintenance due to their non-stick and chemical-resistant properties, significantly reducing the need for abrasive cleaning methods and prolonging the lifespan of equipment. Unlined surfaces, by contrast, often demand regular inspections and protective coatings to prevent corrosion and wear, leading to higher maintenance costs and shorter operational life. The superior durability of Teflon lining results in extended equipment longevity, making it a preferred choice in chemical processing and industrial applications.

Choosing Between Teflon Lined and Unlined Based on Use Case

Teflon lined cookware offers superior non-stick properties and chemical resistance, making it ideal for cooking acidic or sticky foods while requiring less oil for healthier meals. Unlined cookware, often made from stainless steel or cast iron, excels in providing higher heat tolerance and better browning but demands more maintenance and careful seasoning. Selecting between Teflon lined and unlined depends on the user's cooking style, with Teflon preferred for ease of use and quick clean-up, and unlined preferred for high-heat applications and durability.

Teflon Lined vs Unlined Infographic

materialdif.com

materialdif.com