Teflon rod and Teflon tube serve distinct purposes based on their shapes and applications; rods offer solid, cylindrical material ideal for machining into custom parts, while tubes provide hollow, lightweight solutions for fluid transfer or insulation. The choice between a Teflon rod and tube depends on factors such as the need for structural support or the requirement for a passageway in industrial and laboratory settings. Teflon's chemical resistance and low friction properties remain consistent across both forms, ensuring durability and performance in harsh environments.

Table of Comparison

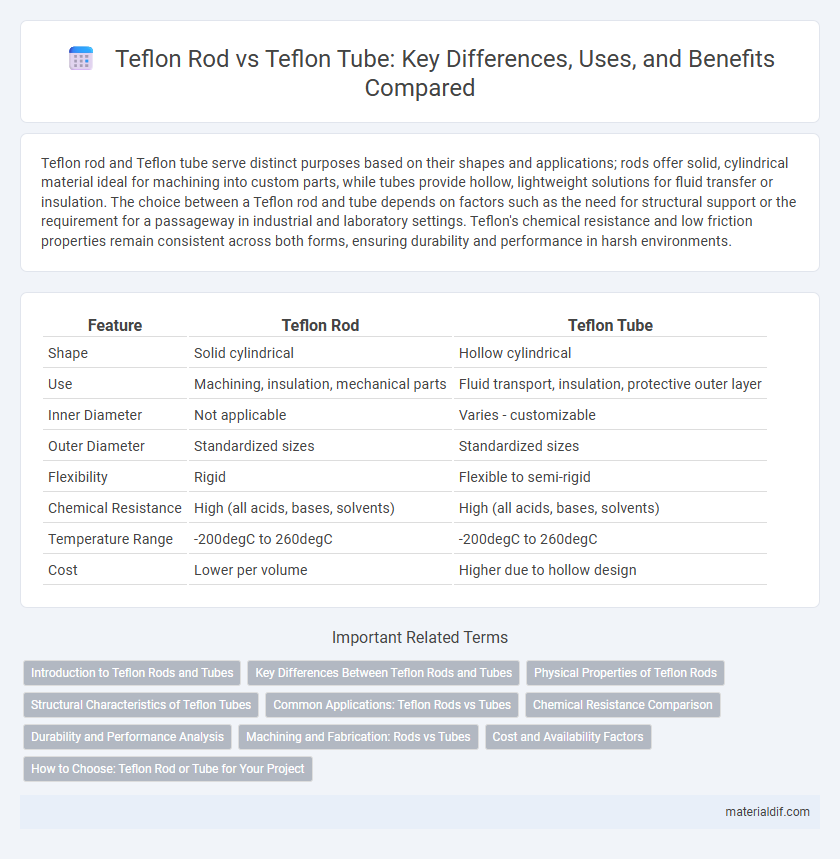

| Feature | Teflon Rod | Teflon Tube |

|---|---|---|

| Shape | Solid cylindrical | Hollow cylindrical |

| Use | Machining, insulation, mechanical parts | Fluid transport, insulation, protective outer layer |

| Inner Diameter | Not applicable | Varies - customizable |

| Outer Diameter | Standardized sizes | Standardized sizes |

| Flexibility | Rigid | Flexible to semi-rigid |

| Chemical Resistance | High (all acids, bases, solvents) | High (all acids, bases, solvents) |

| Temperature Range | -200degC to 260degC | -200degC to 260degC |

| Cost | Lower per volume | Higher due to hollow design |

Introduction to Teflon Rods and Tubes

Teflon rods and tubes are both made from PTFE (polytetrafluoroethylene), known for its exceptional chemical resistance, low friction, and high-temperature tolerance. Teflon rods are solid cylindrical shapes suitable for machining into custom components, while Teflon tubes are hollow and designed for applications requiring fluid or gas flow containment. Both forms utilize Teflon's non-stick and electrical insulating properties but are chosen based on specific dimensional and functional needs.

Key Differences Between Teflon Rods and Tubes

Teflon rods are solid cylindrical shapes used for machining into custom components, offering excellent chemical resistance and low friction, while Teflon tubes are hollow and designed for fluid or gas transport, providing superior insulation and flexibility. The main differences lie in their structure and application: rods serve as raw material for manufacturing parts, whereas tubes function as conduits or protective casings. Teflon tubes typically have precise inner and outer diameters to control flow, whereas rods are valued for their uniform density and mechanical strength.

Physical Properties of Teflon Rods

Teflon rods exhibit uniform density, high chemical resistance, and excellent thermal stability, making them ideal for machining precise components. Their solid cross-section provides superior mechanical strength and wear resistance compared to Teflon tubes, which have hollow interiors designed for fluid transport applications. The low friction coefficient and non-stick surface of Teflon rods enhance their usability in dynamic mechanical parts exposed to harsh environments.

Structural Characteristics of Teflon Tubes

Teflon tubes exhibit superior flexibility and chemical resistance due to their continuous, hollow cylindrical structure, enabling efficient fluid transport in corrosive environments. Their smooth inner surfaces minimize friction and prevent material buildup, enhancing flow dynamics compared to solid Teflon rods. This structural design offers lightweight durability and thermal stability essential in industrial applications such as chemical processing and food manufacturing.

Common Applications: Teflon Rods vs Tubes

Teflon rods are commonly used in manufacturing custom seals, washers, and bearings due to their excellent chemical resistance and high-temperature tolerance. Teflon tubes find frequent application in fluid transfer systems, chemical processing, and electrical insulation where flexibility and durability are required. Both forms leverage PTFE's non-stick properties but differ in structural use depending on mechanical strength or fluid containment needs.

Chemical Resistance Comparison

Teflon rods and tubes both exhibit exceptional chemical resistance due to their polytetrafluoroethylene (PTFE) composition, making them suitable for harsh chemical environments. However, Teflon tubes often provide enhanced protection in dynamic fluid applications, as their hollow structure allows for the containment and transport of aggressive chemicals without degradation. In static or structural uses, Teflon rods deliver comparable chemical resistance, offering durability and stability against corrosive substances.

Durability and Performance Analysis

Teflon rods offer superior durability due to their solid, uniform structure, providing consistent resistance to chemical corrosion and high temperatures, making them ideal for heavy-duty industrial applications. Teflon tubes, while also chemically resistant and temperature stable, are optimized for fluid transport and insulation, with performance influenced by wall thickness and diameter impacting mechanical strength. Choosing between Teflon rod and tube depends on application-specific durability requirements and performance metrics such as tensile strength and flexibility under operational stress.

Machining and Fabrication: Rods vs Tubes

Teflon rods offer superior machinability due to their solid cross-section, allowing precise shaping and customized components without concerns of wall thickness inconsistencies. Teflon tubes require careful consideration of inner and outer diameters during fabrication to maintain structural integrity and avoid deformation under stress. Both forms provide excellent chemical resistance, but rods are preferred for complex machining, while tubes are ideal for fluid transport applications where uniform internal surfaces are critical.

Cost and Availability Factors

Teflon rods generally offer a lower cost per unit compared to Teflon tubes due to simpler manufacturing processes and material usage. Availability of Teflon rods is often higher in standard diameters, making them more accessible for quick procurement. In contrast, Teflon tubes, especially those with precise inner diameter requirements, can be more expensive and less readily stocked in inventory.

How to Choose: Teflon Rod or Tube for Your Project

When deciding between a Teflon rod and a Teflon tube for your project, consider the application's specific requirements such as mechanical strength, flexibility, and fluid containment. Teflon rods provide excellent structural support and are ideal for machining into custom parts, while Teflon tubes excel in fluid transport, offering chemical resistance and low friction for piping or insulation purposes. Selecting the appropriate type based on load bearing, dimensional tolerance, and exposure conditions ensures optimal performance and durability in industrial or laboratory settings.

Teflon Rod vs Teflon Tube Infographic

materialdif.com

materialdif.com