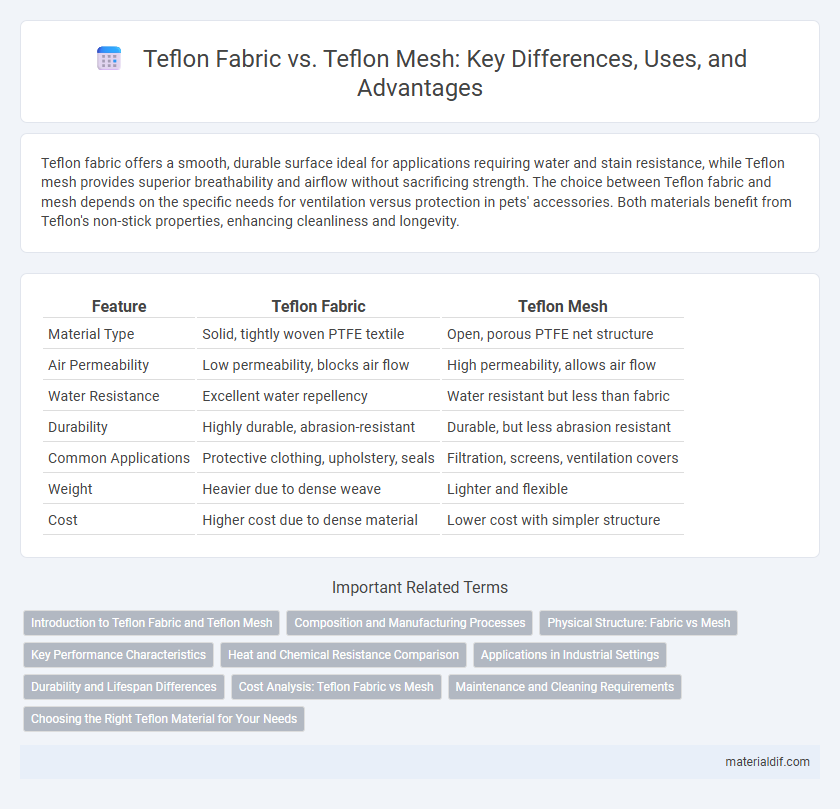

Teflon fabric offers a smooth, durable surface ideal for applications requiring water and stain resistance, while Teflon mesh provides superior breathability and airflow without sacrificing strength. The choice between Teflon fabric and mesh depends on the specific needs for ventilation versus protection in pets' accessories. Both materials benefit from Teflon's non-stick properties, enhancing cleanliness and longevity.

Table of Comparison

| Feature | Teflon Fabric | Teflon Mesh |

|---|---|---|

| Material Type | Solid, tightly woven PTFE textile | Open, porous PTFE net structure |

| Air Permeability | Low permeability, blocks air flow | High permeability, allows air flow |

| Water Resistance | Excellent water repellency | Water resistant but less than fabric |

| Durability | Highly durable, abrasion-resistant | Durable, but less abrasion resistant |

| Common Applications | Protective clothing, upholstery, seals | Filtration, screens, ventilation covers |

| Weight | Heavier due to dense weave | Lighter and flexible |

| Cost | Higher cost due to dense material | Lower cost with simpler structure |

Introduction to Teflon Fabric and Teflon Mesh

Teflon fabric is a durable, non-stick textile coated with polytetrafluoroethylene (PTFE) that offers excellent chemical resistance and high-temperature tolerance. Teflon mesh, made from woven PTFE fibers, provides enhanced breathability and filtration capabilities while maintaining the non-stick and weather-resistant properties of Teflon fabric. Both materials are widely used in industrial applications, with fabric favored for protective coverings and mesh preferred for filtration and separation processes.

Composition and Manufacturing Processes

Teflon fabric is typically composed of polytetrafluoroethylene (PTFE) fibers woven into a durable textile, while Teflon mesh consists of PTFE strands woven in an open, grid-like pattern allowing increased airflow and filtration. The manufacturing of Teflon fabric involves extrusion and stretching of PTFE resin into fine fibers followed by weaving, whereas Teflon mesh requires precise control over strand spacing to maintain structural integrity and permeability. Both materials undergo sintering to enhance chemical resistance and thermal stability, with mesh production demanding additional calibration to balance strength and porosity.

Physical Structure: Fabric vs Mesh

Teflon fabric consists of tightly woven fibers creating a solid, smooth surface ideal for durable, weather-resistant applications. In contrast, Teflon mesh features an open, porous structure with interlaced fibers, allowing for breathability and filtration while maintaining chemical resistance. The physical structure difference directly impacts the performance: fabric offers strength and impermeability, whereas mesh provides ventilation and particulate separation.

Key Performance Characteristics

Teflon fabric offers superior chemical resistance and durability, making it ideal for heavy-duty applications requiring protection from harsh environments. Teflon mesh provides enhanced breathability and flexibility while maintaining excellent non-stick properties, suitable for filtration and lightweight coverings. Both materials exhibit outstanding thermal stability and weather resistance, but fabric tends to be thicker and more robust, whereas mesh ensures better airflow and reduced weight.

Heat and Chemical Resistance Comparison

Teflon fabric offers excellent heat resistance withstanding temperatures up to 260degC (500degF), making it ideal for continuous heat exposure, while Teflon mesh provides slightly lower heat tolerance due to its porous structure. Both materials exhibit outstanding chemical resistance against acids, alkalis, and solvents, but Teflon fabric's denser weave enhances protection against aggressive chemicals under harsh conditions. The choice between Teflon fabric and mesh depends on the balance between heat endurance and the need for breathability or filtration in chemical environments.

Applications in Industrial Settings

Teflon fabric offers superior chemical resistance and durability, making it ideal for protective coverings, conveyor belts, and filtration systems in harsh industrial environments. Teflon mesh, with its fine openings and non-stick properties, is primarily used for screening, sieving, and ventilation applications that require breathability combined with resistance to heat and corrosion. Both materials excel in industries such as chemical processing, food production, and electronics manufacturing, where contamination prevention and longevity are critical.

Durability and Lifespan Differences

Teflon fabric offers enhanced durability with a thicker, tightly woven surface resistant to abrasion and chemicals, resulting in a longer lifespan compared to Teflon mesh. Teflon mesh, while more breathable and flexible, has a more open structure that may degrade faster under heavy mechanical stress or harsh environmental conditions. The lifespan of Teflon fabric typically exceeds that of Teflon mesh in applications requiring robust protection and extended wear resistance.

Cost Analysis: Teflon Fabric vs Mesh

Teflon fabric generally costs more than Teflon mesh due to its denser weave and higher material usage, resulting in enhanced durability and resistance to extreme conditions. Teflon mesh, while more affordable, offers greater breathability and flexibility but may compromise on strength for certain industrial applications. Evaluating cost efficiency requires balancing initial investment against performance longevity and maintenance needs across specific use cases.

Maintenance and Cleaning Requirements

Teflon fabric typically requires less frequent cleaning due to its smooth, non-porous surface that resists dirt and stains, making maintenance straightforward with mild soap and water. Teflon mesh, while also stain-resistant, demands more careful cleaning to prevent debris buildup within the woven structure, often necessitating gentle brushing or low-pressure rinsing to maintain airflow and appearance. Both materials benefit from avoiding harsh chemicals and abrasive tools to preserve their Teflon coating and extend their lifespan.

Choosing the Right Teflon Material for Your Needs

Teflon fabric offers a smooth, chemical-resistant surface ideal for protective clothing and industrial applications requiring flexibility and durability. Teflon mesh provides superior airflow and drainage with high tensile strength, making it suitable for filtration, screening, and outdoor covers. Selecting the right Teflon material depends on whether your priority is barrier protection or breathability for your specific use case.

Teflon Fabric vs Teflon Mesh Infographic

materialdif.com

materialdif.com