Teflon insulators offer superior chemical resistance and excellent electrical insulation, making them ideal for high-temperature applications where durability and non-reactivity are crucial. Ceramic insulators provide outstanding thermal stability and mechanical strength, often preferred in environments with extreme heat and mechanical stress. Choosing between Teflon and ceramic insulators depends on the specific requirements of temperature tolerance, electrical performance, and environmental conditions.

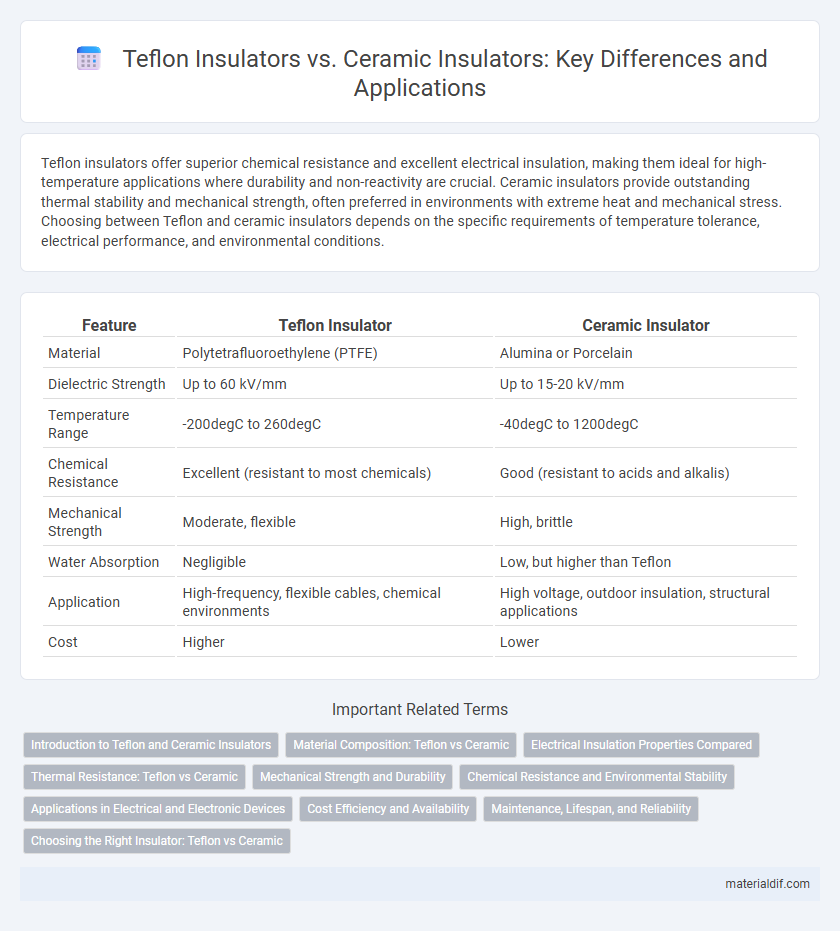

Table of Comparison

| Feature | Teflon Insulator | Ceramic Insulator |

|---|---|---|

| Material | Polytetrafluoroethylene (PTFE) | Alumina or Porcelain |

| Dielectric Strength | Up to 60 kV/mm | Up to 15-20 kV/mm |

| Temperature Range | -200degC to 260degC | -40degC to 1200degC |

| Chemical Resistance | Excellent (resistant to most chemicals) | Good (resistant to acids and alkalis) |

| Mechanical Strength | Moderate, flexible | High, brittle |

| Water Absorption | Negligible | Low, but higher than Teflon |

| Application | High-frequency, flexible cables, chemical environments | High voltage, outdoor insulation, structural applications |

| Cost | Higher | Lower |

Introduction to Teflon and Ceramic Insulators

Teflon insulators, made from polytetrafluoroethylene (PTFE), offer exceptional chemical resistance and low dielectric constant, making them ideal for high-frequency and harsh environment applications. Ceramic insulators, composed of alumina or porcelain, provide superior thermal stability, mechanical strength, and high dielectric strength, widely used in high-voltage and high-temperature settings. Both materials serve critical roles in electrical insulation, with Teflon excelling in flexibility and chemical inertness, and ceramics dominating in thermal endurance and mechanical robustness.

Material Composition: Teflon vs Ceramic

Teflon insulators are made from polytetrafluoroethylene (PTFE), a synthetic fluoropolymer known for its excellent chemical resistance, low dielectric constant, and superior non-stick properties. Ceramic insulators consist primarily of alumina or porcelain, which provide high mechanical strength, thermal stability, and exceptional electrical insulation under high voltage conditions. The choice between Teflon and ceramic insulators depends on the application's temperature range, chemical exposure, and mechanical stress requirements.

Electrical Insulation Properties Compared

Teflon insulators exhibit exceptional dielectric strength, typically around 60 to 120 kV/mm, making them highly effective in preventing electrical conduction. Ceramic insulators, however, offer superior thermal stability and maintain consistent insulation performance under extreme temperatures, with dielectric strength generally ranging from 20 to 40 kV/mm. While Teflon excels in flexibility and chemical resistance, ceramic insulators provide higher mechanical toughness and are favored in high-voltage, high-temperature applications.

Thermal Resistance: Teflon vs Ceramic

Teflon insulators exhibit excellent thermal resistance with a continuous operating temperature of up to 260degC, making them suitable for moderate heat environments. Ceramic insulators withstand significantly higher temperatures, often exceeding 1000degC, due to their inherent material composition, making them ideal for high-temperature applications. The superior thermal resistance of ceramic insulators provides enhanced durability and performance in extreme thermal conditions compared to Teflon.

Mechanical Strength and Durability

Teflon insulators offer excellent mechanical strength with high flexibility and resistance to impact, making them ideal for dynamic applications where vibration or movement occurs. Ceramic insulators, however, provide superior durability under extreme temperature and weather conditions due to their hardness and resistance to thermal shock. While Teflon excels in flexibility and chemical resistance, ceramic insulators dominate in maintaining structural integrity over long-term exposure to harsh environments.

Chemical Resistance and Environmental Stability

Teflon insulators exhibit exceptional chemical resistance, withstanding exposure to aggressive solvents, acids, and bases without degradation, making them ideal for harsh industrial environments. Ceramic insulators also offer strong chemical resistance but can be susceptible to surface cracking under prolonged chemical attack. In terms of environmental stability, Teflon maintains its properties over a wide temperature range and resists UV radiation and moisture absorption better than ceramic counterparts.

Applications in Electrical and Electronic Devices

Teflon insulators offer excellent electrical insulation and high resistance to heat and chemicals, making them ideal for use in high-frequency and high-temperature electronic components such as coaxial cables and circuit boards. Ceramic insulators provide superior mechanical strength and thermal stability, commonly applied in high-voltage power equipment and industrial electronic devices requiring durability under extreme conditions. Both materials enhance electrical performance but are selected based on specific application demands like thermal tolerance and mechanical robustness.

Cost Efficiency and Availability

Teflon insulators offer superior chemical resistance and flexibility at a higher cost compared to ceramic insulators, which are generally more affordable and widely available due to established manufacturing processes. Ceramic insulators provide excellent thermal and electrical insulation with long service life, making them cost-efficient for high-volume industrial applications. Availability of ceramic insulators is greater globally, while Teflon insulators may require specialized suppliers, impacting lead time and overall procurement costs.

Maintenance, Lifespan, and Reliability

Teflon insulators exhibit superior chemical resistance and hydrophobic properties, leading to minimal maintenance and excellent long-term reliability in harsh environments. Ceramic insulators, known for their mechanical strength and durability, typically offer a longer lifespan but require regular cleaning to prevent performance degradation due to pollution accumulation. Both materials provide reliable insulation, but Teflon's low maintenance and resistance to contamination make it ideal for applications prioritizing ease of upkeep and consistent performance.

Choosing the Right Insulator: Teflon vs Ceramic

Teflon insulators offer superior chemical resistance and flexibility, making them ideal for applications requiring durability against corrosive environments and dynamic movement. Ceramic insulators excel in high-temperature stability and electrical insulation, preferred in environments with extreme heat and electrical stress. Choosing the right insulator depends on balancing the need for thermal endurance versus chemical resistance and mechanical flexibility.

Teflon insulator vs Ceramic insulator Infographic

materialdif.com

materialdif.com