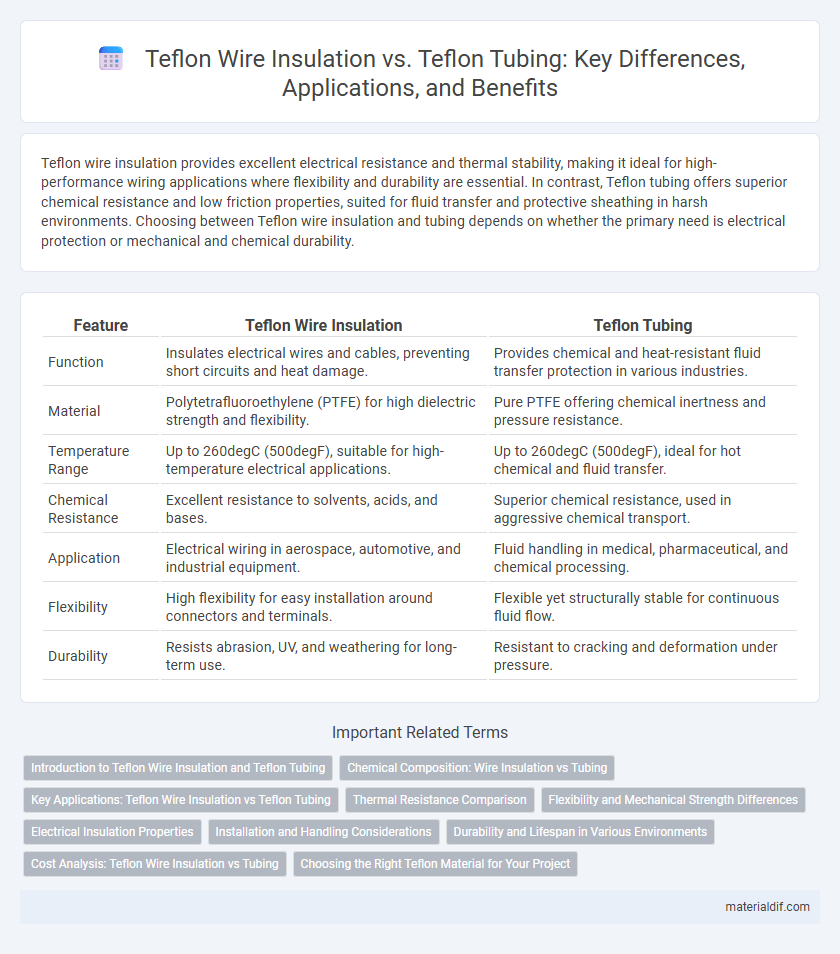

Teflon wire insulation provides excellent electrical resistance and thermal stability, making it ideal for high-performance wiring applications where flexibility and durability are essential. In contrast, Teflon tubing offers superior chemical resistance and low friction properties, suited for fluid transfer and protective sheathing in harsh environments. Choosing between Teflon wire insulation and tubing depends on whether the primary need is electrical protection or mechanical and chemical durability.

Table of Comparison

| Feature | Teflon Wire Insulation | Teflon Tubing |

|---|---|---|

| Function | Insulates electrical wires and cables, preventing short circuits and heat damage. | Provides chemical and heat-resistant fluid transfer protection in various industries. |

| Material | Polytetrafluoroethylene (PTFE) for high dielectric strength and flexibility. | Pure PTFE offering chemical inertness and pressure resistance. |

| Temperature Range | Up to 260degC (500degF), suitable for high-temperature electrical applications. | Up to 260degC (500degF), ideal for hot chemical and fluid transfer. |

| Chemical Resistance | Excellent resistance to solvents, acids, and bases. | Superior chemical resistance, used in aggressive chemical transport. |

| Application | Electrical wiring in aerospace, automotive, and industrial equipment. | Fluid handling in medical, pharmaceutical, and chemical processing. |

| Flexibility | High flexibility for easy installation around connectors and terminals. | Flexible yet structurally stable for continuous fluid flow. |

| Durability | Resists abrasion, UV, and weathering for long-term use. | Resistant to cracking and deformation under pressure. |

Introduction to Teflon Wire Insulation and Teflon Tubing

Teflon wire insulation provides exceptional thermal stability, chemical resistance, and electrical insulation for wires in demanding environments, making it ideal for aerospace, automotive, and industrial applications. Teflon tubing offers superior flexibility, high temperature tolerance, and chemical inertness, serving as a protective conduit for fluids and gases in medical, chemical processing, and food industries. Both materials leverage polytetrafluoroethylene (PTFE) properties but differ in their primary function: wire insulation safeguards electrical conductors, while tubing channels fluids safely.

Chemical Composition: Wire Insulation vs Tubing

Teflon wire insulation and Teflon tubing both utilize polytetrafluoroethylene (PTFE) as their base material, offering exceptional chemical resistance and thermal stability. Wire insulation often incorporates fillers and modifications to enhance flexibility and electrical properties, while tubing typically maintains purer PTFE for superior chemical inertness and mechanical strength. Differences in chemical composition directly affect performance characteristics, making wire insulation optimized for electrical applications and tubing suited for fluid transfer in harsh chemical environments.

Key Applications: Teflon Wire Insulation vs Teflon Tubing

Teflon wire insulation is primarily used in high-temperature electrical applications, such as aerospace wiring, automotive engines, and medical devices, due to its excellent dielectric properties and resistance to heat, chemicals, and abrasion. Teflon tubing finds key applications in chemical processing, pharmaceutical delivery systems, and food processing industries where corrosion resistance, flexibility, and non-reactivity with aggressive fluids are critical. Both materials leverage PTFE's unique thermal stability and chemical inertness but serve distinct purposes: insulation for electrical protection versus protective conduit for fluid transport.

Thermal Resistance Comparison

Teflon wire insulation offers exceptional thermal resistance withstanding continuous temperatures up to 260degC, making it ideal for high-heat electrical applications. Teflon tubing also exhibits comparable thermal stability but provides enhanced mechanical protection against heat exposure in fluid transfer systems. Both materials maintain their insulating properties under extreme temperatures, but wire insulation is specifically engineered to prevent electrical failure, while tubing prioritizes chemical and thermal durability.

Flexibility and Mechanical Strength Differences

Teflon wire insulation offers superior flexibility, allowing it to bend and conform to tight spaces without cracking, making it ideal for dynamic cable applications. In contrast, Teflon tubing provides enhanced mechanical strength and abrasion resistance, suitable for protective coverings and fluid transfer systems subjected to wear and pressure. The choice between Teflon wire insulation and tubing depends on the balance between required flexibility for wiring configurations and the mechanical durability needed for environmental exposure.

Electrical Insulation Properties

Teflon wire insulation provides exceptional dielectric strength and thermal resistance, making it ideal for high-voltage electrical applications. In contrast, Teflon tubing is designed primarily for chemical resistance and fluid transport, with less emphasis on electrical insulating performance. The superior electrical insulation properties of Teflon wire coatings ensure minimal signal loss and protection against electrical interference in demanding environments.

Installation and Handling Considerations

Teflon wire insulation offers superior flexibility and abrasion resistance, making it easier to route and install in tight spaces compared to Teflon tubing, which requires careful cutting and fitting to ensure a proper seal. The high melting point of Teflon wire insulation allows for heat-resistant applications without deformation during soldering or high-temperature operations, whereas Teflon tubing demands precise handling to avoid damage and maintain its insulating properties. Both materials require clean, oil-free conditions during installation to optimize their dielectric performance and longevity in electrical and fluid systems.

Durability and Lifespan in Various Environments

Teflon wire insulation offers exceptional durability with resistance to high temperatures, chemicals, and abrasion, making it ideal for electrical applications in harsh environments. Teflon tubing, engineered for fluid transfer, provides superior chemical inertness and mechanical strength, ensuring a longer lifespan in corrosive or high-pressure settings. Both solutions maintain stability across extreme temperatures ranging from -200degC to 260degC, but the choice depends on the specific environmental demands such as flexing for wires or pressure resistance for tubing.

Cost Analysis: Teflon Wire Insulation vs Tubing

Teflon wire insulation generally incurs lower costs compared to Teflon tubing due to reduced material thickness and simpler manufacturing processes. Teflon tubing requires more raw material and precise extrusion techniques, driving up production expenses. Cost efficiency is influenced by application-specific factors such as required durability, flexibility, and thermal resistance.

Choosing the Right Teflon Material for Your Project

Teflon wire insulation provides exceptional electrical resistance, high-temperature tolerance up to 260degC, and chemical inertness, making it ideal for intricate wiring and electronic applications. Teflon tubing offers superior flexibility, low friction, and excellent resistance to corrosive chemicals, suited for fluid transfer and protective conduit uses. Selecting the right Teflon material depends on environmental exposure, mechanical stress, and thermal requirements specific to your project's demands.

Teflon Wire Insulation vs Teflon Tubing Infographic

materialdif.com

materialdif.com