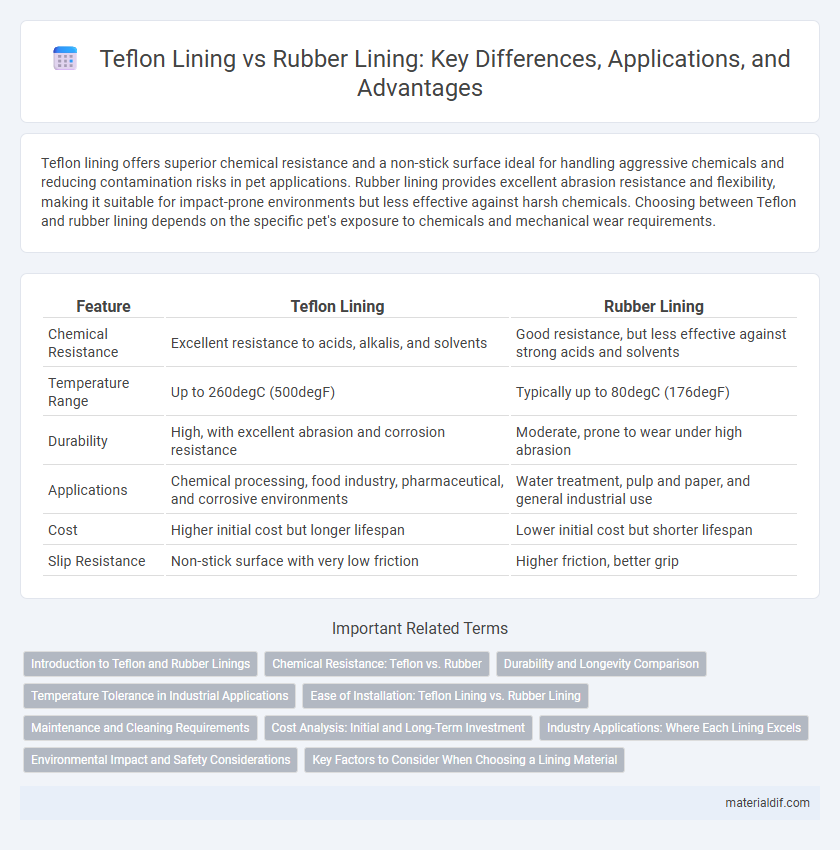

Teflon lining offers superior chemical resistance and a non-stick surface ideal for handling aggressive chemicals and reducing contamination risks in pet applications. Rubber lining provides excellent abrasion resistance and flexibility, making it suitable for impact-prone environments but less effective against harsh chemicals. Choosing between Teflon and rubber lining depends on the specific pet's exposure to chemicals and mechanical wear requirements.

Table of Comparison

| Feature | Teflon Lining | Rubber Lining |

|---|---|---|

| Chemical Resistance | Excellent resistance to acids, alkalis, and solvents | Good resistance, but less effective against strong acids and solvents |

| Temperature Range | Up to 260degC (500degF) | Typically up to 80degC (176degF) |

| Durability | High, with excellent abrasion and corrosion resistance | Moderate, prone to wear under high abrasion |

| Applications | Chemical processing, food industry, pharmaceutical, and corrosive environments | Water treatment, pulp and paper, and general industrial use |

| Cost | Higher initial cost but longer lifespan | Lower initial cost but shorter lifespan |

| Slip Resistance | Non-stick surface with very low friction | Higher friction, better grip |

Introduction to Teflon and Rubber Linings

Teflon lining, made from polytetrafluoroethylene (PTFE), offers exceptional chemical resistance and a low coefficient of friction, making it ideal for applications involving corrosive substances and high temperatures. Rubber lining provides superior abrasion resistance and flexibility, excelling in environments with mechanical wear and impact. Both linings serve critical roles in industrial equipment, with Teflon favored for chemical inertness and rubber for durability and shock absorption.

Chemical Resistance: Teflon vs. Rubber

Teflon lining offers superior chemical resistance compared to rubber lining, with excellent inertness to acids, bases, solvents, and aggressive chemicals, making it ideal for highly corrosive environments. Rubber lining, while resistant to certain chemicals like alkalis and mild acids, generally degrades faster under exposure to strong acids, solvents, and oxidizing agents. Industries requiring long-term durability against harsh chemical exposure prefer Teflon lining to ensure maximum protection and extended equipment lifespan.

Durability and Longevity Comparison

Teflon lining offers superior chemical resistance and can withstand high temperatures up to 260degC, ensuring exceptional durability in harsh environments. Rubber lining, while providing good abrasion resistance and flexibility, tends to degrade faster when exposed to aggressive chemicals and extreme heat. The longevity of Teflon lining typically surpasses rubber lining in industrial applications requiring sustained exposure to corrosive substances and high operational temperatures.

Temperature Tolerance in Industrial Applications

Teflon lining offers superior temperature tolerance compared to rubber lining, withstanding continuous temperatures up to 260degC (500degF) and occasional spikes higher, making it ideal for high-heat industrial applications. Rubber lining generally tolerates temperatures up to 80degC to 120degC (176degF to 248degF), limiting its use in processes involving elevated temperatures or thermal cycling. This thermal resilience of Teflon ensures enhanced durability and chemical resistance in harsh environments such as chemical processing, where high-temperature exposure is common.

Ease of Installation: Teflon Lining vs. Rubber Lining

Teflon lining offers greater ease of installation due to its flexible, lightweight properties and resistance to chemical degradation, allowing for quicker fitment in complex or irregular shapes. In contrast, rubber lining requires more careful handling because it is heavier and prone to damage during installation, often necessitating specialized skills and longer downtime. The low friction surface of Teflon also facilitates smoother adjustments and alignment, minimizing labor costs and installation time.

Maintenance and Cleaning Requirements

Teflon lining offers superior chemical resistance and non-stick properties, significantly reducing cleaning frequency and maintenance efforts compared to rubber lining. Its smooth, non-porous surface prevents material build-up and facilitates easier removal of residues, enhancing operational efficiency. Rubber lining, while durable against corrosion, often requires more rigorous cleaning procedures and frequent inspections due to its porous texture and susceptibility to abrasion.

Cost Analysis: Initial and Long-Term Investment

Teflon lining generally demands a higher initial investment compared to rubber lining due to its advanced chemical resistance and temperature tolerance capabilities. Over the long term, Teflon's durability reduces maintenance and replacement costs, often offsetting the upfront expense. Rubber lining, while cheaper initially, may incur greater costs over time due to lower resistance to abrasion and chemical degradation in aggressive environments.

Industry Applications: Where Each Lining Excels

Teflon lining excels in chemical processing industries due to its exceptional resistance to corrosive acids, solvents, and high temperatures, making it ideal for reactors, tanks, and piping systems exposed to aggressive chemicals. Rubber lining outperforms in industries requiring abrasion resistance and impact protection, such as mining, wastewater treatment, and pulp and paper, where handling slurries and abrasive materials demands durability and flexibility. Selecting between Teflon and rubber linings depends on specific industry conditions, with Teflon suited for chemical inertness and thermal stability, while rubber offers superior mechanical protection and resilience against wear.

Environmental Impact and Safety Considerations

Teflon lining offers exceptional chemical resistance and non-reactivity, reducing contamination risks and minimizing hazardous waste generation compared to rubber lining, which can degrade and release harmful substances into the environment. The high durability and inert properties of Teflon enhance workplace safety by preventing leaks and exposure to corrosive materials, whereas rubber linings may pose higher risks of failure and toxic emissions. Choosing Teflon lining supports sustainable industrial practices through its long lifespan and lower environmental footprint relative to frequently replaced rubber alternatives.

Key Factors to Consider When Choosing a Lining Material

Teflon lining offers exceptional chemical resistance and high-temperature tolerance, making it ideal for handling aggressive corrosive substances in industrial applications. Rubber lining provides superior impact resistance and flexibility, suited for abrasive materials and environments requiring cushioning. Key factors to consider when choosing a lining material include chemical compatibility, temperature range, mechanical wear resistance, and the specific operational conditions of the equipment.

Teflon Lining vs Rubber Lining Infographic

materialdif.com

materialdif.com