Perfluoroalkoxy (PFA) offers greater chemical resistance and higher temperature tolerance than Polytetrafluoroethylene (PTFE), making it ideal for advanced pet care tools requiring durability. PTFE exhibits superior non-stick properties and exceptional lubrication, which benefits everyday pet products like grooming brushes and feeding bowls. Choosing between PFA and PTFE depends on specific performance needs such as heat resistance versus surface smoothness in pet applications.

Table of Comparison

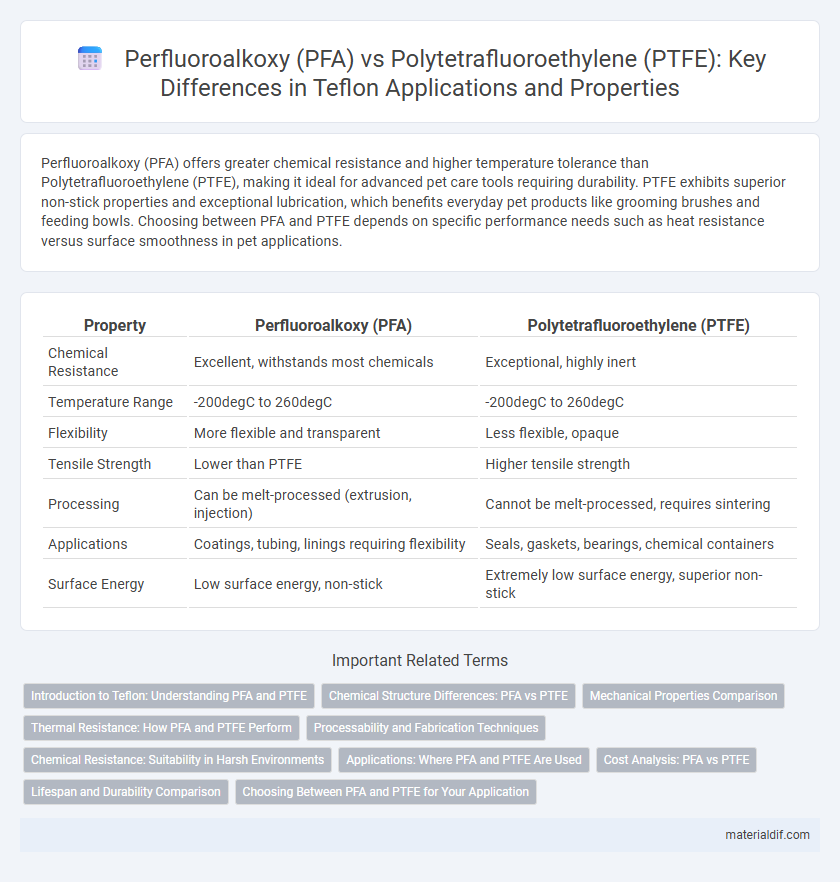

| Property | Perfluoroalkoxy (PFA) | Polytetrafluoroethylene (PTFE) |

|---|---|---|

| Chemical Resistance | Excellent, withstands most chemicals | Exceptional, highly inert |

| Temperature Range | -200degC to 260degC | -200degC to 260degC |

| Flexibility | More flexible and transparent | Less flexible, opaque |

| Tensile Strength | Lower than PTFE | Higher tensile strength |

| Processing | Can be melt-processed (extrusion, injection) | Cannot be melt-processed, requires sintering |

| Applications | Coatings, tubing, linings requiring flexibility | Seals, gaskets, bearings, chemical containers |

| Surface Energy | Low surface energy, non-stick | Extremely low surface energy, superior non-stick |

Introduction to Teflon: Understanding PFA and PTFE

Perfluoroalkoxy (PFA) and Polytetrafluoroethylene (PTFE) are two prominent types of Teflon known for their exceptional chemical resistance and non-stick properties. PTFE features a high melting point of around 327degC and superior thermal stability, making it ideal for high-temperature applications, while PFA offers greater flexibility and transparency with melting temperatures near 305degC. Both polymers find extensive use in industries such as chemical processing, electronics, and cookware coatings due to their unique molecular structures and performance characteristics.

Chemical Structure Differences: PFA vs PTFE

Perfluoroalkoxy (PFA) and Polytetrafluoroethylene (PTFE) both belong to the fluoropolymer family but differ in chemical structure, which impacts their properties. PTFE consists of a linear chain of carbon atoms fully fluorinated with single bonds, giving it exceptional chemical resistance and thermal stability. PFA incorporates perfluoroalkoxy side chains in its polymer backbone, enhancing its flexibility and melt-processability compared to PTFE, making it suitable for complex shapes and applications requiring greater mechanical strength.

Mechanical Properties Comparison

Perfluoroalkoxy (PFA) exhibits greater flexibility and higher elongation at break compared to Polytetrafluoroethylene (PTFE), offering improved impact resistance in dynamic applications. PTFE demonstrates superior tensile strength and excellent chemical resistance, making it ideal for static sealing and insulating components. Both materials provide high thermal stability, but PFA's enhanced mechanical resilience allows for better performance in environments with frequent mechanical stress.

Thermal Resistance: How PFA and PTFE Perform

Perfluoroalkoxy (PFA) and Polytetrafluoroethylene (PTFE) both exhibit exceptional thermal resistance, with PTFE maintaining stability up to approximately 260degC and PFA performing well slightly higher, tolerating continuous use temperatures near 260-280degC. PTFE's melting point is around 327degC, providing superior thermal endurance in static conditions, while PFA offers enhanced flexibility and abrasion resistance at elevated temperatures. The choice between PFA and PTFE depends on operational requirements such as continuous thermal exposure, mechanical stress, and chemical environment in high-temperature applications.

Processability and Fabrication Techniques

Perfluoroalkoxy (PFA) offers superior processability compared to Polytetrafluoroethylene (PTFE) due to its melt-processable nature, allowing techniques like injection molding and extrusion that PTFE cannot undergo. PTFE requires specialized fabrication methods such as sintering and paste extrusion because it decomposes before melting, limiting its versatility in manufacturing. The enhanced flow characteristics of PFA facilitate complex shapes and tighter tolerances, making it advantageous for applications demanding precise and scalable production.

Chemical Resistance: Suitability in Harsh Environments

Perfluoroalkoxy (PFA) and Polytetrafluoroethylene (PTFE) exhibit exceptional chemical resistance, making both ideal for use in harsh environments with aggressive chemicals. PFA maintains superior transparency and flexibility at elevated temperatures while resisting acids, bases, and solvents commonly found in industrial applications. PTFE offers outstanding inertness and low friction with resistance to nearly all chemicals but lacks PFA's clarity and flexibility under thermal stress.

Applications: Where PFA and PTFE Are Used

Perfluoroalkoxy (PFA) is widely used in applications requiring excellent chemical resistance and transparency, such as in semiconductor manufacturing, pharmaceutical equipment, and chemical processing linings. Polytetrafluoroethylene (PTFE) is commonly found in non-stick cookware coatings, gaskets, seals, and electrical insulation due to its superior heat resistance and low friction properties. Both PFA and PTFE are essential in industries demanding high-performance fluoropolymer materials for corrosion resistance and thermal stability.

Cost Analysis: PFA vs PTFE

Perfluoroalkoxy (PFA) generally incurs higher production costs than polytetrafluoroethylene (PTFE) due to its more complex manufacturing process and superior melt processability. PTFE offers a cost-effective solution with excellent chemical resistance and thermal stability but lacks the easy extrusion and welding capabilities of PFA, which can increase fabrication expenses. Selecting between PFA and PTFE demands careful evaluation of total lifecycle costs, including raw material expenses, processing techniques, and application-specific performance benefits.

Lifespan and Durability Comparison

Perfluoroalkoxy (PFA) and Polytetrafluoroethylene (PTFE) both exhibit exceptional chemical resistance and non-stick properties, but PTFE generally offers a longer lifespan under high wear conditions due to its greater abrasion resistance. PFA provides superior flexibility and impact resistance, which enhances durability in dynamic applications where bending or thermal cycling occurs. PTFE is preferred in static, harsh chemical environments requiring extended service life, while PFA is favored where mechanical stress and thermal expansion play crucial roles in material longevity.

Choosing Between PFA and PTFE for Your Application

Perfluoroalkoxy (PFA) and Polytetrafluoroethylene (PTFE) both offer exceptional chemical resistance and thermal stability, with PFA providing superior clarity and flexibility ideal for applications requiring transparency and intricate shapes. PTFE exhibits a lower coefficient of friction and higher resistance to deformation under load, making it suitable for high-wear or load-bearing environments. Selecting between PFA and PTFE depends on specific application needs such as chemical exposure, temperature range, mechanical properties, and fabrication requirements.

Perfluoroalkoxy (PFA) vs Polytetrafluoroethylene (PTFE) Infographic

materialdif.com

materialdif.com