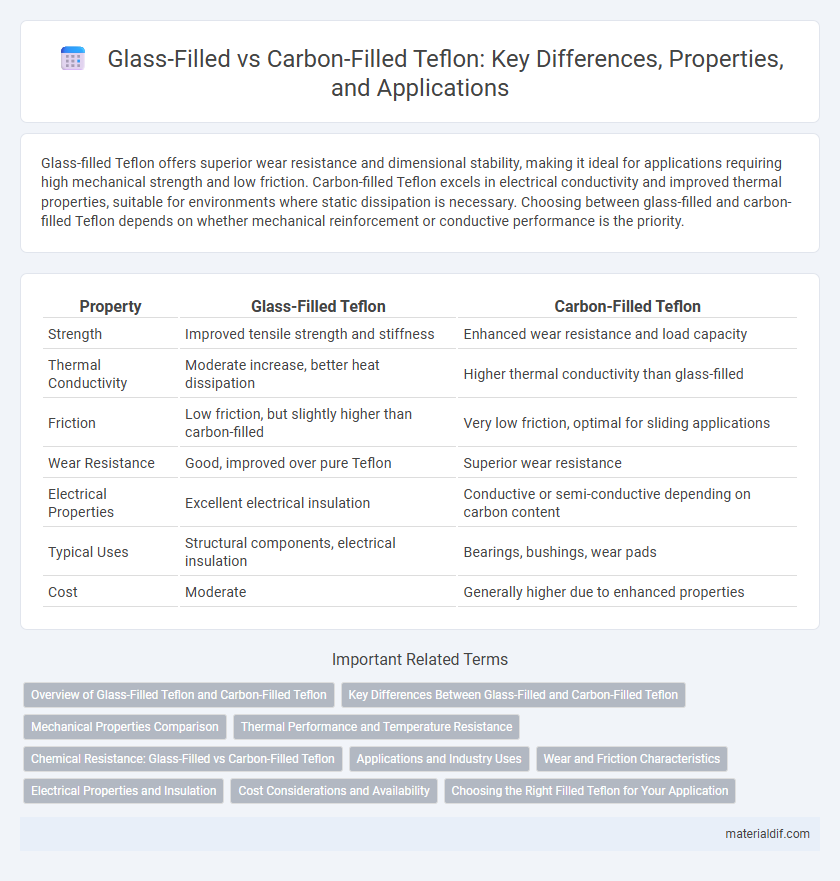

Glass-filled Teflon offers superior wear resistance and dimensional stability, making it ideal for applications requiring high mechanical strength and low friction. Carbon-filled Teflon excels in electrical conductivity and improved thermal properties, suitable for environments where static dissipation is necessary. Choosing between glass-filled and carbon-filled Teflon depends on whether mechanical reinforcement or conductive performance is the priority.

Table of Comparison

| Property | Glass-Filled Teflon | Carbon-Filled Teflon |

|---|---|---|

| Strength | Improved tensile strength and stiffness | Enhanced wear resistance and load capacity |

| Thermal Conductivity | Moderate increase, better heat dissipation | Higher thermal conductivity than glass-filled |

| Friction | Low friction, but slightly higher than carbon-filled | Very low friction, optimal for sliding applications |

| Wear Resistance | Good, improved over pure Teflon | Superior wear resistance |

| Electrical Properties | Excellent electrical insulation | Conductive or semi-conductive depending on carbon content |

| Typical Uses | Structural components, electrical insulation | Bearings, bushings, wear pads |

| Cost | Moderate | Generally higher due to enhanced properties |

Overview of Glass-Filled Teflon and Carbon-Filled Teflon

Glass-filled Teflon combines polytetrafluoroethylene (PTFE) with glass fibers, enhancing its mechanical strength, dimensional stability, and resistance to creep, making it ideal for applications requiring high wear resistance and improved rigidity. Carbon-filled Teflon incorporates carbon fibers or graphite into PTFE, providing superior electrical conductivity, improved wear resistance, and reduced friction, suitable for conductive or low-friction components. Both composites maintain the chemical resistance and low coefficient of friction typical of pure Teflon but differ significantly in mechanical and electrical properties depending on the filler material.

Key Differences Between Glass-Filled and Carbon-Filled Teflon

Glass-filled Teflon exhibits higher stiffness and improved dimensional stability due to the inclusion of glass fibers, making it ideal for applications requiring enhanced mechanical strength. Carbon-filled Teflon offers superior electrical conductivity and improved wear resistance, suited for environments demanding static dissipation and lower friction. The key differences lie in their reinforcement materials, affecting thermal expansion, mechanical properties, and electrical performance.

Mechanical Properties Comparison

Glass-filled Teflon exhibits higher stiffness and improved dimensional stability compared to carbon-filled Teflon, making it ideal for applications requiring enhanced rigidity and wear resistance. Carbon-filled Teflon offers superior electrical conductivity and better impact strength, beneficial in environments where electrical dissipation and toughness are critical. Mechanical property selection depends on balancing rigidity and conductivity requirements for specific engineering applications.

Thermal Performance and Temperature Resistance

Glass-filled Teflon offers superior thermal performance with a higher continuous operating temperature of up to 260degC, making it ideal for applications requiring enhanced heat resistance. Carbon-filled Teflon, while slightly lower in temperature tolerance around 230degC, provides excellent thermal conductivity and reduced electrical resistance. Both materials improve the base Teflon's temperature resistance, but glass-filled variants excel in thermal stability for high-heat environments.

Chemical Resistance: Glass-Filled vs Carbon-Filled Teflon

Glass-filled Teflon exhibits superior chemical resistance compared to carbon-filled Teflon, maintaining stability in highly corrosive environments such as strong acids and bases. Carbon-filled Teflon enhances mechanical strength and electrical conductivity but may show reduced resistance to aggressive chemicals, particularly oxidizing agents. Selecting glass-filled Teflon ensures optimal performance in applications requiring maximum chemical inertness and durability against harsh chemicals.

Applications and Industry Uses

Glass-filled Teflon offers enhanced rigidity and dimensional stability, making it ideal for aerospace components, electrical insulation, and chemical processing equipment where mechanical strength and thermal stability are critical. Carbon-filled Teflon provides improved electrical conductivity and wear resistance, preferred in applications like electronic housings, automotive parts, and industrial machinery requiring static dissipation and abrasion resistance. Both materials serve niche markets within the chemical, automotive, and electronics industries, optimizing performance based on specific physical and chemical demands.

Wear and Friction Characteristics

Glass-filled Teflon offers superior wear resistance and dimensional stability due to its rigid glass fibers, making it ideal for applications requiring high durability and low friction. Carbon-filled Teflon enhances electrical conductivity while providing moderate wear resistance and friction reduction, suitable for environments with electrical or static dissipation needs. Both composites lower the inherent friction of pure Teflon, but glass-filled variants excel in minimizing wear under mechanical stress.

Electrical Properties and Insulation

Glass-filled Teflon offers superior electrical insulation and high dielectric strength, making it ideal for applications requiring excellent electrical resistance and dimensional stability under load. Carbon-filled Teflon provides enhanced electrical conductivity while maintaining good thermal stability, suitable for dissipating static charges and preventing electrical buildup. The choice between the two depends on whether insulating properties or electrical conductivity is prioritized in the specific application.

Cost Considerations and Availability

Glass-filled Teflon offers higher strength at a moderate cost and is widely available for industrial applications, making it a cost-effective choice for enhanced durability. Carbon-filled Teflon is generally more expensive due to its superior conductivity and wear resistance but may be less readily available in certain markets. Both materials balance cost and performance differently, with glass-filled variants favored for budget-sensitive projects and carbon-filled preferred when advanced properties justify the higher expense.

Choosing the Right Filled Teflon for Your Application

Glass-filled Teflon offers enhanced stiffness, higher strength, and improved dimensional stability, making it ideal for applications requiring wear resistance and low friction under heavy loads. Carbon-filled Teflon provides superior electrical conductivity and better thermal stability, suitable for components exposed to electrical or thermal stresses. Selecting the right filled Teflon depends on balancing mechanical performance, electrical properties, and environmental conditions to optimize longevity and functionality.

Glass-Filled Teflon vs Carbon-Filled Teflon Infographic

materialdif.com

materialdif.com