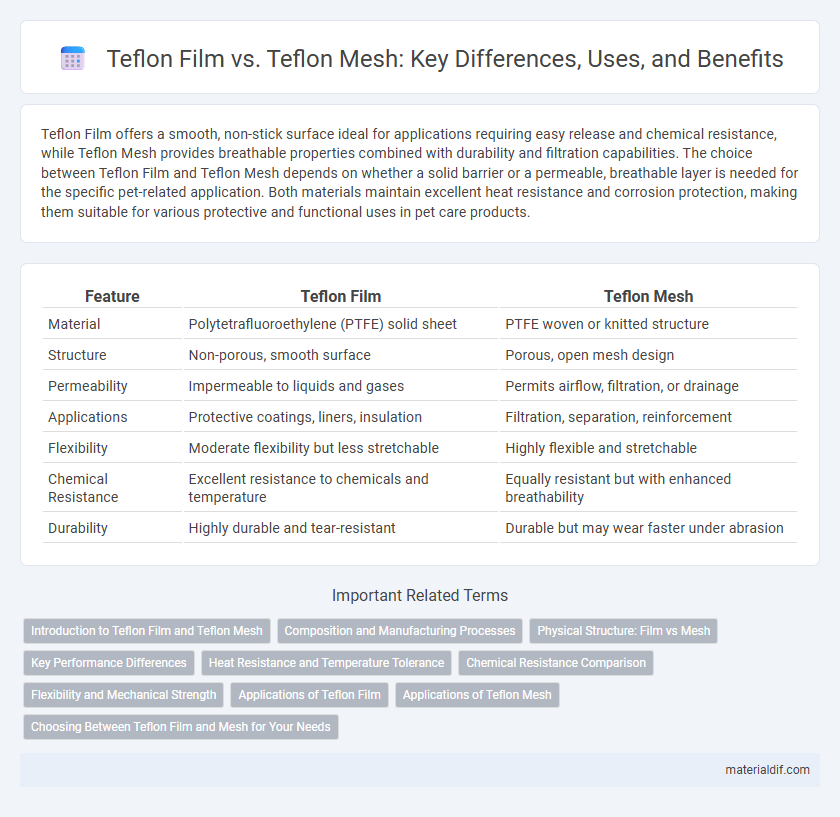

Teflon Film offers a smooth, non-stick surface ideal for applications requiring easy release and chemical resistance, while Teflon Mesh provides breathable properties combined with durability and filtration capabilities. The choice between Teflon Film and Teflon Mesh depends on whether a solid barrier or a permeable, breathable layer is needed for the specific pet-related application. Both materials maintain excellent heat resistance and corrosion protection, making them suitable for various protective and functional uses in pet care products.

Table of Comparison

| Feature | Teflon Film | Teflon Mesh |

|---|---|---|

| Material | Polytetrafluoroethylene (PTFE) solid sheet | PTFE woven or knitted structure |

| Structure | Non-porous, smooth surface | Porous, open mesh design |

| Permeability | Impermeable to liquids and gases | Permits airflow, filtration, or drainage |

| Applications | Protective coatings, liners, insulation | Filtration, separation, reinforcement |

| Flexibility | Moderate flexibility but less stretchable | Highly flexible and stretchable |

| Chemical Resistance | Excellent resistance to chemicals and temperature | Equally resistant but with enhanced breathability |

| Durability | Highly durable and tear-resistant | Durable but may wear faster under abrasion |

Introduction to Teflon Film and Teflon Mesh

Teflon film is a thin, non-stick, and chemically resistant layer commonly used for insulation, protective coverings, and industrial applications requiring a smooth surface. Teflon mesh consists of woven or knitted fibers coated with Teflon, offering enhanced breathability, flexibility, and filtration capabilities. Both Teflon film and mesh leverage polytetrafluoroethylene's (PTFE) properties but serve distinct functions based on their structural differences.

Composition and Manufacturing Processes

Teflon film is a thin, dense sheet made from expanded polytetrafluoroethylene (ePTFE) through a process of stretching and calendaring, resulting in a smooth, non-porous surface ideal for chemical resistance and insulation. In contrast, Teflon mesh is fabricated by weaving or knitting PTFE fibers into an open, porous structure that provides excellent airflow and drainage properties. The distinct manufacturing techniques create differences in density, flexibility, and permeability, tailoring each form for specific industrial applications.

Physical Structure: Film vs Mesh

Teflon film features a smooth, continuous surface that provides excellent non-stick and chemical resistance properties, making it ideal for applications requiring airtight seals and uniform coverage. In contrast, Teflon mesh consists of a woven network of fibers, offering superior breathability and flexibility while maintaining high temperature and chemical resistance. The physical structure of Teflon mesh enables drainage and filtration uses, whereas Teflon film is favored for barrier and insulation purposes.

Key Performance Differences

Teflon film offers superior non-stick properties and chemical resistance, making it ideal for applications requiring smooth, impermeable surfaces. In contrast, Teflon mesh provides enhanced breathability and flexibility, supporting filtration and reinforcement tasks with its porous structure. The choice between Teflon film and mesh hinges on whether impermeability or permeability is essential for the specific industrial or manufacturing process.

Heat Resistance and Temperature Tolerance

Teflon film offers superior heat resistance with a temperature tolerance typically up to 260degC (500degF), making it ideal for applications requiring a smooth, non-stick surface that withstands continuous high heat. Teflon mesh, while also heat resistant, generally has a slightly lower temperature tolerance due to its porous structure, often capping around 230degC (446degF), which suits uses needing airflow and filtration but less extreme thermal exposure. The dense, non-porous composition of Teflon film ensures consistent thermal insulation and chemical resistance, whereas Teflon mesh balances moderate heat endurance with flexibility and breathability.

Chemical Resistance Comparison

Teflon film exhibits superior chemical resistance compared to Teflon mesh due to its non-porous, solid structure that prevents penetration by aggressive acids, bases, and solvents. The mesh form, while still resistant to many chemicals, has an open-weave design that can allow certain substances to pass through, reducing its protective effectiveness in harsh chemical environments. For applications requiring maximum chemical inertness and barrier properties, Teflon film is the preferred choice over Teflon mesh.

Flexibility and Mechanical Strength

Teflon film offers superior flexibility, making it ideal for applications requiring smooth, continuous surfaces with excellent chemical resistance. In contrast, Teflon mesh provides enhanced mechanical strength and durability due to its woven structure, which allows for better load distribution and dimensional stability. Selecting between Teflon film and mesh depends on the balance needed between flexibility and tensile strength for specific industrial uses.

Applications of Teflon Film

Teflon film is widely used in electrical insulation, non-stick coatings for cookware, and protective layers in chemical processing industries due to its excellent dielectric properties, chemical resistance, and low friction. It serves as a reliable barrier in high-temperature applications such as gasket seals, flexible packaging, and printed circuit boards. The smooth, homogeneous surface of Teflon film makes it ideal for applications requiring contamination prevention and easy cleaning compared to Teflon mesh.

Applications of Teflon Mesh

Teflon mesh is widely used in applications requiring filtration, separation, and protection due to its porous structure and chemical resistance. Industries such as pharmaceuticals, food processing, and electronics rely on Teflon mesh for its ability to withstand high temperatures and corrosive environments while allowing airflow or liquid passage. Unlike Teflon film, which is primarily used for surface protection and insulation, Teflon mesh excels in scenarios demanding mechanical strength and permeability.

Choosing Between Teflon Film and Mesh for Your Needs

Teflon film offers a smooth, non-stick surface ideal for applications requiring consistent heat resistance and chemical inertness, making it suitable for gasket seals and insulation. Teflon mesh provides enhanced air flow and filtration capabilities, perfect for sieving, straining, and drying processes in industrial settings. Selecting between Teflon film and mesh depends on whether your priority is impermeable, durable coverage or breathable, filtering functionality.

Teflon Film vs Teflon Mesh Infographic

materialdif.com

materialdif.com