Extruded Teflon is produced by forcing softened resin through a die, creating continuous shapes ideal for tubes, rods, and sheets with uniform density. Molded Teflon involves pressing powdered resin into a mold and sintering, resulting in complex, precise shapes with enhanced mechanical strength. Extruded Teflon offers better chemical resistance, while molded Teflon provides superior dimensional stability and resistance to deformation under stress.

Table of Comparison

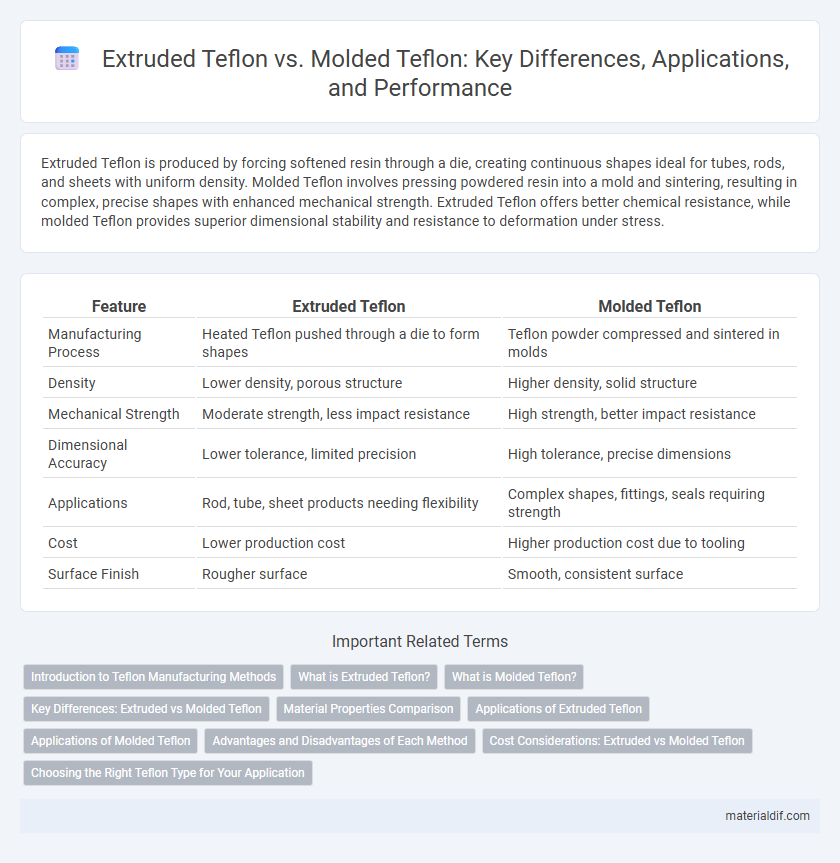

| Feature | Extruded Teflon | Molded Teflon |

|---|---|---|

| Manufacturing Process | Heated Teflon pushed through a die to form shapes | Teflon powder compressed and sintered in molds |

| Density | Lower density, porous structure | Higher density, solid structure |

| Mechanical Strength | Moderate strength, less impact resistance | High strength, better impact resistance |

| Dimensional Accuracy | Lower tolerance, limited precision | High tolerance, precise dimensions |

| Applications | Rod, tube, sheet products needing flexibility | Complex shapes, fittings, seals requiring strength |

| Cost | Lower production cost | Higher production cost due to tooling |

| Surface Finish | Rougher surface | Smooth, consistent surface |

Introduction to Teflon Manufacturing Methods

Extruded Teflon is produced by forcing PTFE resin through a die to create uniform shapes, offering enhanced mechanical properties and dimensional control. Molded Teflon is formed by compressing PTFE powder into a mold and sintering, allowing for complex geometries but with potential for lower density and strength compared to extrusion. These manufacturing methods influence the final characteristics, density, porosity, and performance of Teflon components in industrial applications.

What is Extruded Teflon?

Extruded Teflon is a form of polytetrafluoroethylene (PTFE) created by forcing softened resin through a specialized die to produce continuous shapes such as rods, tubes, or sheets. This process results in a uniform, homogenous material with enhanced mechanical strength and excellent chemical resistance, suitable for industrial seals, gaskets, and insulating components. Unlike molded Teflon, extruded Teflon offers more consistent dimensional stability and can be machined to precise tolerances for customized applications.

What is Molded Teflon?

Molded Teflon refers to polytetrafluoroethylene (PTFE) shaped using heat and pressure in a mold, allowing for complex geometries and high precision components. This process results in parts with consistent density, improved mechanical strength, and enhanced chemical resistance compared to extruded Teflon. Molded Teflon is ideal for applications requiring intricate designs and superior durability, such as seals, gaskets, and custom industrial parts.

Key Differences: Extruded vs Molded Teflon

Extruded Teflon is produced by forcing softened polymer through a die, resulting in continuous shapes with consistent cross-sections, ideal for tubing and rods. Molded Teflon is formed by compressing and heating powdered resin in a mold, allowing for complex shapes and precise dimensions suited for custom parts. Extruded Teflon generally has improved mechanical strength and uniformity, while molded Teflon offers greater design flexibility and tight tolerance control.

Material Properties Comparison

Extruded Teflon exhibits uniform density and superior mechanical strength, making it ideal for high-stress sealing applications. Molded Teflon, formed under heat and pressure, offers enhanced dimensional stability and the ability to produce intricate shapes with consistent surface finish. Both materials provide excellent chemical resistance and low friction, but extruded Teflon typically has higher tensile strength while molded Teflon excels in complex geometries.

Applications of Extruded Teflon

Extruded Teflon is widely used in applications requiring uniform thickness and excellent chemical resistance, such as gaskets, seals, and insulation films in the electrical industry. Its high mechanical strength and smooth surface make it ideal for tubing and pipe linings in pharmaceutical and food processing equipment. This manufacturing process allows for precise dimensional tolerances, critical for components exposed to corrosive environments and high temperatures.

Applications of Molded Teflon

Molded Teflon is commonly used in applications requiring complex shapes and high chemical resistance, such as seals, gaskets, and valve components in the chemical, pharmaceutical, and food processing industries. Its ability to withstand extreme temperatures and provide excellent electrical insulation makes it ideal for aerospace and electrical insulation applications. Molded Teflon's precise dimensional stability and non-stick properties enhance performance in semiconductor fabrication and medical devices.

Advantages and Disadvantages of Each Method

Extruded Teflon offers superior dimensional consistency and is ideal for uniform, continuous shapes such as rods and tubes, but it may have limitations in producing complex geometries. Molded Teflon allows for intricate designs and thicker parts with enhanced mechanical strength but can be more expensive and prone to internal voids or imperfections. Choosing between extruded and molded Teflon depends on the required part complexity, mechanical properties, and production volume.

Cost Considerations: Extruded vs Molded Teflon

Extruded Teflon typically offers lower production costs due to continuous shaping processes and minimal tooling expenses, making it more economical for large-volume runs. Molded Teflon involves higher upfront costs from custom molds and complex manufacturing, but it enables intricate shapes and precise dimensional control, justifying expenses for specialized applications. Cost efficiency depends on part complexity, production volume, and tolerance requirements when choosing between extruded and molded Teflon.

Choosing the Right Teflon Type for Your Application

Extruded Teflon offers uniform density and excellent mechanical strength, ideal for applications requiring precise dimensions and consistent performance under pressure. Molded Teflon provides complex shapes with high chemical resistance, suited for custom parts in aggressive chemical environments. Selecting the right Teflon type depends on factors like required tolerances, mechanical stress, and exposure to chemicals.

Extruded Teflon vs Molded Teflon Infographic

materialdif.com

materialdif.com