Granular PTFE features larger, coarse particles that provide superior mechanical strength and are ideal for applications requiring enhanced wear resistance. Fine powder PTFE consists of much smaller particles, resulting in smoother finishes and better flow properties, making it suitable for coatings and molding processes. Choosing between granular and fine powder PTFE depends on the specific performance requirements, such as durability versus surface smoothness.

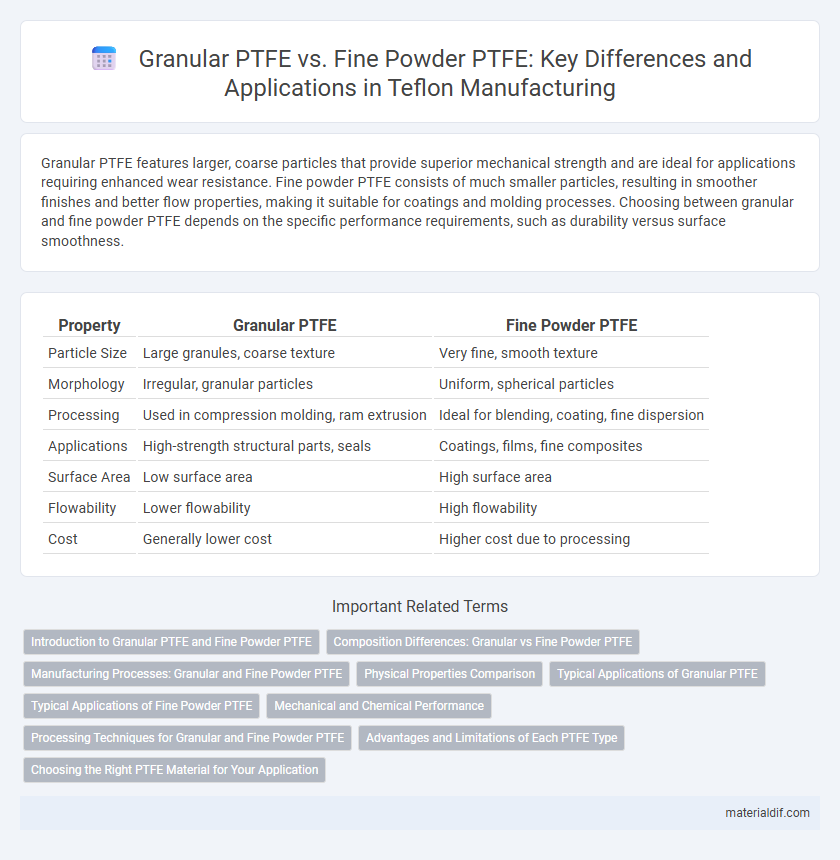

Table of Comparison

| Property | Granular PTFE | Fine Powder PTFE |

|---|---|---|

| Particle Size | Large granules, coarse texture | Very fine, smooth texture |

| Morphology | Irregular, granular particles | Uniform, spherical particles |

| Processing | Used in compression molding, ram extrusion | Ideal for blending, coating, fine dispersion |

| Applications | High-strength structural parts, seals | Coatings, films, fine composites |

| Surface Area | Low surface area | High surface area |

| Flowability | Lower flowability | High flowability |

| Cost | Generally lower cost | Higher cost due to processing |

Introduction to Granular PTFE and Fine Powder PTFE

Granular PTFE consists of larger, uniform particles typically ranging from 100 to 300 microns, offering excellent flow characteristics and ease of processing in molding and extrusion applications. Fine Powder PTFE features particles below 50 microns, providing superior surface finish and enhanced sintering properties essential for producing dense, high-strength components. Both forms of PTFE enable specific performance benefits tailored to industrial uses such as lubrication, chemical resistance, and high-temperature stability.

Composition Differences: Granular vs Fine Powder PTFE

Granular PTFE consists of larger, coarser particles that enhance flow and ease of handling during processing, while fine powder PTFE features much smaller particles offering a higher surface area for improved sintering and more uniform dispersion in composites. The molecular structure remains consistent in both forms, but the particle size distribution significantly influences their respective processing characteristics and final application performance. Granular PTFE is often favored for molding and extrusion, whereas fine powder PTFE is preferred for coatings and fine composite fabrication due to its superior blending capability.

Manufacturing Processes: Granular and Fine Powder PTFE

Granular PTFE is produced by suspension polymerization, resulting in bead-like particles that facilitate uniform molding and sintering, ideal for extrusion and compression molding applications. Fine powder PTFE undergoes emulsion polymerization and is characterized by smaller particle size, enhancing sintering speed and yielding smoother, denser finished parts ideal for precision coatings. Understanding these manufacturing distinctions optimizes PTFE's performance in applications demanding specific mechanical and thermal properties.

Physical Properties Comparison

Granular PTFE exhibits larger particle size and higher bulk density compared to fine powder PTFE, enhancing flowability and ease of processing in molding applications. Fine powder PTFE offers superior surface finish and greater sinterability due to its smaller particle size, enabling finer detail replication and improved mechanical strength. Both forms maintain excellent chemical resistance and thermal stability, but granular PTFE is preferred for compression molding while fine powder PTFE suits applications requiring precision and smooth coatings.

Typical Applications of Granular PTFE

Granular PTFE is commonly used in the manufacturing of seals, gaskets, and bearings due to its ease of processing and excellent mechanical properties. Its coarser particle size provides superior flow characteristics in compression molding and extrusion processes, making it ideal for producing intricate shapes in automotive, chemical, and food processing industries. Granular PTFE is favored for applications requiring high chemical resistance and low friction under mechanical stress.

Typical Applications of Fine Powder PTFE

Fine Powder PTFE is extensively used in applications requiring excellent flow properties and uniform dispersion, such as coatings, sealants, and lubricants. Its smaller particle size enables superior surface finish and consistent mixing in composite materials and paints. Fine Powder PTFE also excels in producing high-performance gaskets and membranes due to its enhanced mechanical strength and chemical resistance.

Mechanical and Chemical Performance

Granular PTFE exhibits superior mechanical properties such as enhanced tensile strength and wear resistance due to its larger particle size, making it ideal for heavy-duty industrial applications. Fine powder PTFE offers improved chemical performance with greater surface area facilitating faster sintering and better chemical inertness, suitable for applications requiring high purity and corrosion resistance. Both forms maintain excellent chemical stability, but granular PTFE is preferred for mechanical durability while fine powder excels in precision coating and sealing tasks.

Processing Techniques for Granular and Fine Powder PTFE

Granular PTFE is typically processed using ram extrusion and compression molding, leveraging its coarse particle size for easier handling and flow during shaping. Fine powder PTFE, with its much smaller particle size, is suited for techniques like paste extrusion and fine powder compaction, allowing for more detailed and precise molding. Selection of processing techniques directly affects the material's density, mechanical properties, and surface finish in final applications.

Advantages and Limitations of Each PTFE Type

Granular PTFE offers superior melt flow and ease of processing in molding applications, making it ideal for producing complex shapes with consistent mechanical properties. Fine powder PTFE provides enhanced dispersion in composites and coatings, delivering better surface finish and improved electrical insulation characteristics due to its smaller particle size. However, granular PTFE may exhibit slower sintering times and less uniform particle distribution, while fine powder PTFE can present challenges in handling due to dust generation and requires precise temperature control to avoid degradation.

Choosing the Right PTFE Material for Your Application

Granular PTFE offers superior machinability and is ideal for applications requiring precise shaping and molding, while Fine Powder PTFE provides enhanced surface finish and is often used in coatings and lubricants due to its fine particle size. Selecting the right PTFE material depends on the application's need for mechanical strength, chemical resistance, and processing methods such as sintering or compression molding. Consider granular PTFE for high-precision components and fine powder PTFE for smooth coatings and fine-detail applications to optimize performance and durability.

Granular PTFE vs Fine Powder PTFE Infographic

materialdif.com

materialdif.com