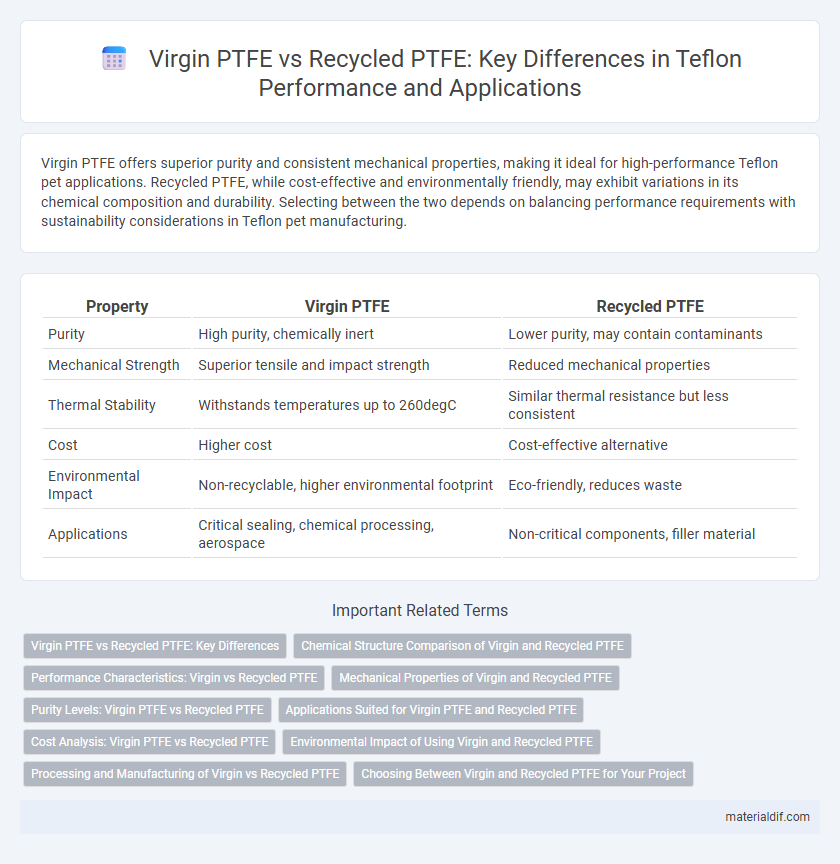

Virgin PTFE offers superior purity and consistent mechanical properties, making it ideal for high-performance Teflon pet applications. Recycled PTFE, while cost-effective and environmentally friendly, may exhibit variations in its chemical composition and durability. Selecting between the two depends on balancing performance requirements with sustainability considerations in Teflon pet manufacturing.

Table of Comparison

| Property | Virgin PTFE | Recycled PTFE |

|---|---|---|

| Purity | High purity, chemically inert | Lower purity, may contain contaminants |

| Mechanical Strength | Superior tensile and impact strength | Reduced mechanical properties |

| Thermal Stability | Withstands temperatures up to 260degC | Similar thermal resistance but less consistent |

| Cost | Higher cost | Cost-effective alternative |

| Environmental Impact | Non-recyclable, higher environmental footprint | Eco-friendly, reduces waste |

| Applications | Critical sealing, chemical processing, aerospace | Non-critical components, filler material |

Virgin PTFE vs Recycled PTFE: Key Differences

Virgin PTFE offers superior chemical purity, enhanced mechanical strength, and consistent performance compared to recycled PTFE, which may contain impurities and exhibit reduced structural integrity. The thermal stability of virgin PTFE remains higher, making it more suitable for demanding industrial applications requiring reliable heat resistance. Recycled PTFE, while cost-effective and environmentally beneficial, often shows variability in molecular weight distribution and physical properties, limiting its use in high-precision or critical component manufacturing.

Chemical Structure Comparison of Virgin and Recycled PTFE

Virgin PTFE exhibits a highly crystalline and uniform chemical structure with long, unbroken polymer chains, ensuring superior mechanical performance and chemical resistance. Recycled PTFE often contains shorter polymer chains and minor structural irregularities due to thermal degradation and mechanical processing, which can affect its crystallinity and properties. Despite these differences, both materials maintain the characteristic carbon-fluorine bonds fundamental to PTFE's chemical inertness.

Performance Characteristics: Virgin vs Recycled PTFE

Virgin PTFE offers superior mechanical strength, higher purity, and enhanced chemical resistance compared to recycled PTFE, which may contain impurities and degraded polymer chains. Performance consistency and dielectric properties are more reliable in virgin PTFE, making it ideal for critical applications requiring precise insulation and wear resistance. Recycled PTFE is suitable for less demanding uses where cost is a priority but may exhibit slightly reduced thermal stability and elongation at break.

Mechanical Properties of Virgin and Recycled PTFE

Virgin PTFE exhibits superior mechanical properties, including higher tensile strength, better elongation at break, and enhanced wear resistance compared to recycled PTFE. Recycled PTFE often shows a reduction in molecular weight and possible contamination, leading to decreased impact strength and increased brittleness. These differences make virgin PTFE more suitable for applications demanding high durability and mechanical reliability.

Purity Levels: Virgin PTFE vs Recycled PTFE

Virgin PTFE exhibits superior purity levels, containing minimal impurities and maintaining consistent chemical composition ideal for high-performance applications. Recycled PTFE often contains trace contaminants and altered molecular structures, which can reduce its chemical resistance and mechanical properties. High-purity virgin PTFE is preferred in industries requiring strict material standards, such as aerospace and medical devices.

Applications Suited for Virgin PTFE and Recycled PTFE

Virgin PTFE is ideal for high-performance applications requiring superior chemical resistance, low friction, and exceptional purity, such as in medical devices, aerospace components, and semiconductor manufacturing. Recycled PTFE is suitable for less demanding applications like gasket materials, seals, and industrial linings where cost-efficiency and sustainability are prioritized over maximum material properties. Both forms maintain the core benefits of PTFE but differ significantly in mechanical strength and purity, influencing their respective usage scenarios.

Cost Analysis: Virgin PTFE vs Recycled PTFE

Virgin PTFE typically carries higher production costs due to raw material purity and manufacturing processes, resulting in a premium price point. Recycled PTFE offers significant cost savings by reprocessing scrap materials, reducing expenses related to raw inputs and waste management. However, quality consistency and performance variability in recycled PTFE can influence overall cost-effectiveness depending on application requirements.

Environmental Impact of Using Virgin and Recycled PTFE

Virgin PTFE production consumes significant amounts of energy and raw fluorinated compounds, contributing to greenhouse gas emissions and resource depletion. Recycled PTFE reduces environmental impact by minimizing waste sent to landfills and lowering the demand for virgin fluoropolymers, resulting in decreased carbon footprint and energy consumption. Implementing recycled PTFE in manufacturing supports circular economy practices and reduces reliance on non-renewable resources.

Processing and Manufacturing of Virgin vs Recycled PTFE

Virgin PTFE offers superior consistency and purity in processing, resulting in enhanced mechanical properties and chemical resistance during manufacturing. Recycled PTFE may contain contaminants that affect melt flow and sintering behavior, requiring modified processing parameters to maintain product quality. Manufacturers often balance cost savings of recycled PTFE with potential trade-offs in uniformity and long-term durability in end-use applications.

Choosing Between Virgin and Recycled PTFE for Your Project

Virgin PTFE offers superior purity and consistent performance, making it ideal for applications requiring high chemical resistance and electrical insulation. Recycled PTFE provides a cost-effective and environmentally friendly alternative, suitable for less demanding uses where slight variations in material properties are acceptable. Selecting between virgin and recycled PTFE depends on project specifications regarding mechanical strength, contamination tolerance, and budget constraints.

virgin PTFE vs recycled PTFE Infographic

materialdif.com

materialdif.com