Teflon sintering involves heating powdered PTFE to create a solid, uniform material with enhanced chemical resistance and mechanical strength, ideal for seals and gaskets. Skiving, on the other hand, is a precision machining process that slices thin sheets or films from PTFE rods or billets, offering tight thickness tolerances for applications requiring fine dimensional control. Both methods serve different purposes in Teflon pet production, with sintering geared towards bulk material formation and skiving suited for producing thin, flat components.

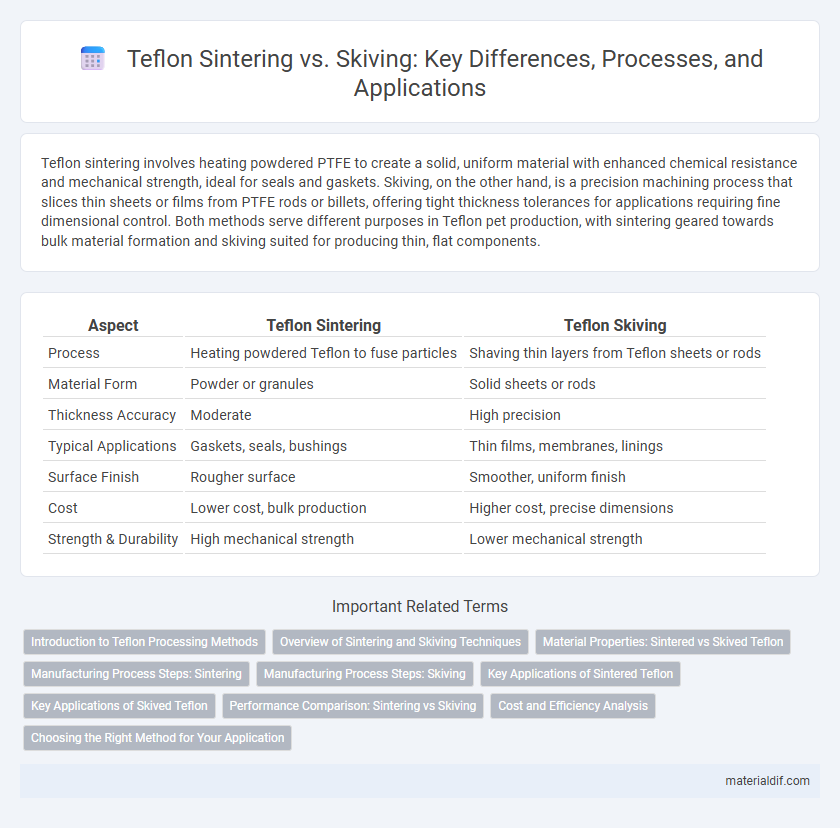

Table of Comparison

| Aspect | Teflon Sintering | Teflon Skiving |

|---|---|---|

| Process | Heating powdered Teflon to fuse particles | Shaving thin layers from Teflon sheets or rods |

| Material Form | Powder or granules | Solid sheets or rods |

| Thickness Accuracy | Moderate | High precision |

| Typical Applications | Gaskets, seals, bushings | Thin films, membranes, linings |

| Surface Finish | Rougher surface | Smoother, uniform finish |

| Cost | Lower cost, bulk production | Higher cost, precise dimensions |

| Strength & Durability | High mechanical strength | Lower mechanical strength |

Introduction to Teflon Processing Methods

Teflon processing methods like sintering and skiving are essential for achieving different material properties and applications. Sintering involves heating powdered Teflon below its melting point to fuse particles, creating dense, durable products with excellent chemical resistance. Skiving removes thin layers from Teflon sheets or rods, providing precise thickness control for seals, gaskets, and other tight-tolerance components.

Overview of Sintering and Skiving Techniques

Teflon sintering involves heating polytetrafluoroethylene (PTFE) powder above its melting point to fuse particles into a cohesive solid, enhancing mechanical strength and chemical resistance. Skiving is a precise mechanical process that slices thin PTFE sheets from bulk billets, producing uniform thickness and smooth surface finishes ideal for seals and gaskets. Both techniques enable customized Teflon components, with sintering optimizing structural integrity and skiving ensuring dimensional accuracy.

Material Properties: Sintered vs Skived Teflon

Sintered Teflon exhibits enhanced mechanical strength and chemical resistance due to its dense, interconnected polymer matrix formed during the high-temperature sintering process. Skived Teflon sheets, produced by slicing thin films from extruded blocks, offer superior surface smoothness and dimensional accuracy but may have reduced tensile strength compared to sintered counterparts. The choice between sintered and skived Teflon depends on the application's requirements for durability, flexibility, and chemical exposure.

Manufacturing Process Steps: Sintering

Teflon sintering involves heating the polymer powder just below its melting point, causing the particles to fuse into a solid, dense form without melting entirely. This process enhances the material's mechanical strength and chemical resistance, making it ideal for high-performance applications. Precise temperature control during sintering is critical to avoid degradation and ensure uniformity in the final Teflon product.

Manufacturing Process Steps: Skiving

Skiving in Teflon manufacturing involves precisely slicing thin sheets or films from sintered Teflon blocks using a rotating blade, enabling uniform thickness and smooth surface finish. This process ensures dimensional accuracy and enhances mechanical properties by removing surface irregularities post-sintering. Skiving is essential for producing high-quality Teflon gaskets, seals, and films used in industrial applications requiring chemical resistance and low friction.

Key Applications of Sintered Teflon

Sintered Teflon offers exceptional chemical resistance and low friction properties, making it ideal for seals, bearings, and gaskets in aggressive chemical environments. Its enhanced mechanical strength and dimensional stability enable precise components in pharmaceutical, food processing, and semiconductor manufacturing industries. These applications rely on sintered Teflon's ability to maintain integrity under extreme temperatures and corrosive conditions, outperforming skived alternatives in durability and performance.

Key Applications of Skived Teflon

Skived Teflon is widely used in dynamic sealing applications such as piston and rod seals in hydraulic cylinders due to its superior dimensional stability and smooth surface finish. Its precise thin film production enables reliable insulation and protection in electrical components, including semiconductor manufacturing and printed circuit boards. This method is also favored in chemical processing industries for gaskets and lining materials that require excellent chemical resistance and low friction.

Performance Comparison: Sintering vs Skiving

Teflon sintering enhances chemical resistance and mechanical strength, creating a uniform, dense structure ideal for high-performance applications. Skiving offers precise thickness control and smooth surface finishes but may result in slightly lower durability compared to sintered Teflon. Performance comparison shows sintered Teflon excels in wear resistance and high-temperature stability, while skived Teflon provides advantages in customization and surface quality.

Cost and Efficiency Analysis

Teflon sintering offers higher material density and superior mechanical properties but involves longer processing times and increased energy costs compared to skiving, which is faster and more cost-effective for producing thin, uniform sheets. Skiving reduces waste by precisely slicing sintered blocks, enhancing efficiency in large-scale manufacturing despite potential size limitations. Cost analysis favors sintering for high-performance applications requiring durability, while skiving suits volume-driven production due to lower operational expenses.

Choosing the Right Method for Your Application

Teflon sintering involves heating powdered PTFE to fuse particles into a solid, creating strong, uniform parts ideal for high-performance chemical and electrical insulation applications. Skiving, on the other hand, precisely slices thin PTFE sheets from extruded blocks, providing smooth surfaces suitable for sealing and gasket applications requiring tight tolerances. Selecting between sintering and skiving depends on the desired mechanical properties, surface finish, and dimensional accuracy essential for your specific Teflon application.

Teflon Sintering vs Skiving Infographic

materialdif.com

materialdif.com