Teflon coating involves applying a thin, non-stick layer directly onto the surface of pet products, enhancing durability and making cleaning easier without altering the material's texture. Teflon lamination, by contrast, bonds a Teflon film onto the fabric, providing a stronger barrier against stains and moisture while maintaining flexibility. Both methods improve pet product performance, but choosing between them depends on the desired balance of protection, feel, and manufacturing process.

Table of Comparison

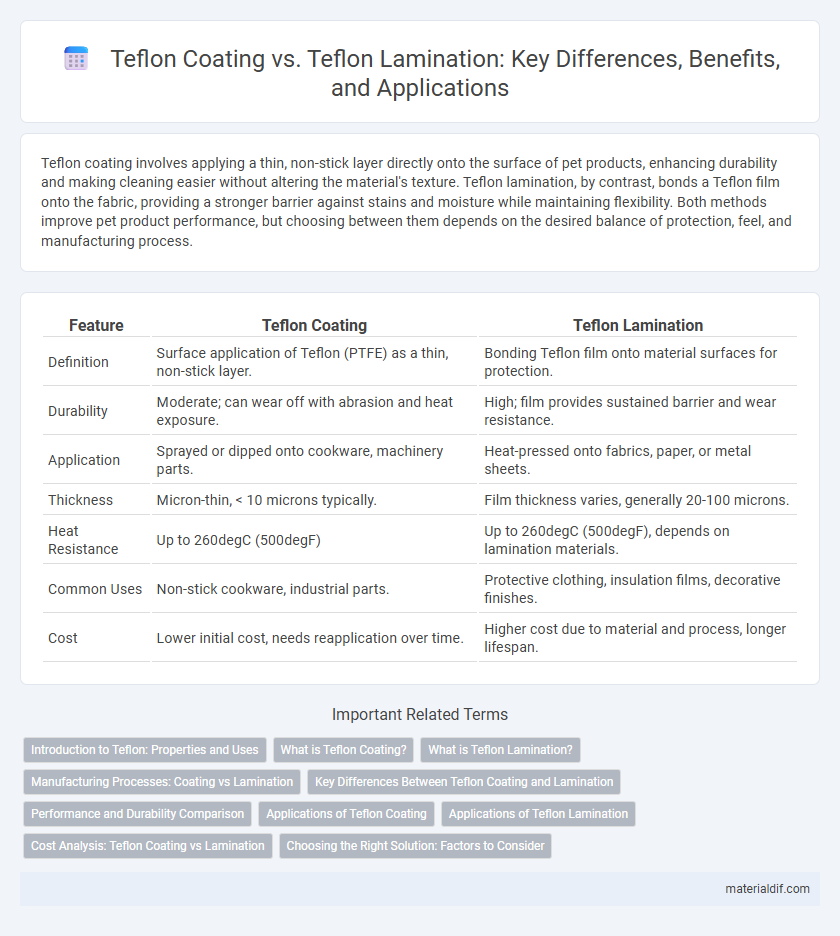

| Feature | Teflon Coating | Teflon Lamination |

|---|---|---|

| Definition | Surface application of Teflon (PTFE) as a thin, non-stick layer. | Bonding Teflon film onto material surfaces for protection. |

| Durability | Moderate; can wear off with abrasion and heat exposure. | High; film provides sustained barrier and wear resistance. |

| Application | Sprayed or dipped onto cookware, machinery parts. | Heat-pressed onto fabrics, paper, or metal sheets. |

| Thickness | Micron-thin, < 10 microns typically. | Film thickness varies, generally 20-100 microns. |

| Heat Resistance | Up to 260degC (500degF) | Up to 260degC (500degF), depends on lamination materials. |

| Common Uses | Non-stick cookware, industrial parts. | Protective clothing, insulation films, decorative finishes. |

| Cost | Lower initial cost, needs reapplication over time. | Higher cost due to material and process, longer lifespan. |

Introduction to Teflon: Properties and Uses

Teflon, a brand name for polytetrafluoroethylene (PTFE), is renowned for its non-stick, chemical-resistant, and heat-resistant properties, making it ideal for various industrial and household applications. Teflon coating involves applying a thin PTFE layer on surfaces to provide a non-stick, low-friction finish commonly used in cookware, automotive parts, and electronics. In contrast, Teflon lamination integrates PTFE films into materials to enhance durability, chemical resistance, and insulation, frequently used in fabric and aerospace industries.

What is Teflon Coating?

Teflon coating is a chemical process where a thin layer of polytetrafluoroethylene (PTFE) is applied to the surface of cookware, fabrics, or industrial equipment to provide non-stick, anti-corrosive, and friction-reducing properties. This coating enhances durability and resistance to heat and chemicals, making it ideal for high-performance applications. Unlike lamination, which involves bonding a Teflon film onto a material, Teflon coating creates a seamless, uniform protective layer directly on the substrate.

What is Teflon Lamination?

Teflon lamination involves bonding a thin layer of Teflon film onto fabric or paper to create a durable, non-stick, and water-resistant surface that maintains flexibility. Unlike Teflon coating, which applies a liquid polymer directly onto a substrate and cures it, lamination uses heat and pressure to adhere the pre-formed Teflon film. This method enhances the material's resistance to stains, chemicals, and abrasion while preserving breathability and tensile strength.

Manufacturing Processes: Coating vs Lamination

Teflon coating involves applying a thin layer of polytetrafluoroethylene (PTFE) onto a substrate through processes like spraying, dipping, or electrostatic methods, resulting in a non-stick, heat-resistant surface. Teflon lamination combines PTFE films with other materials by heat and pressure bonding, creating a composite structure with enhanced mechanical strength and chemical resistance. Manufacturing processes for coating enable flexibility and thin coverage, whereas lamination ensures durability and thickness for industrial applications.

Key Differences Between Teflon Coating and Lamination

Teflon coating involves the application of a non-stick, chemical-resistant layer directly onto surfaces, providing enhanced durability and ease of cleaning, while Teflon lamination consists of bonding a thin Teflon film onto a substrate for added protection and flexibility. The coating process typically offers better adhesion and higher heat resistance compared to lamination, which is more suitable for flexible materials and decorative finishes. Key differences include the application methods, thickness, adhesion strength, and intended use cases, with coating preferred for industrial and cookware applications and lamination favored in textiles and packaging.

Performance and Durability Comparison

Teflon coating offers superior non-stick performance and enhanced resistance to heat, chemicals, and corrosion, making it ideal for cookware and industrial applications. Teflon lamination provides a protective layer bonded to surfaces, improving durability against scratching and wear but with slightly reduced non-stick efficiency compared to pure Teflon coatings. Both methods extend product lifespan, yet coatings generally deliver higher performance in terms of longevity and resistance under harsh conditions.

Applications of Teflon Coating

Teflon coating is extensively used in cookware, automotive parts, and industrial machinery for its non-stick, chemical-resistant, and low-friction properties, enhancing durability and performance. Unlike Teflon lamination, which involves layering for enhanced barrier protection in packaging and textiles, Teflon coating is directly applied to surfaces, offering corrosion resistance and easy cleaning in aerospace and electronics industries. Its versatility makes Teflon coating essential in sectors demanding heat resistance and reduced wear, such as food processing equipment and medical devices.

Applications of Teflon Lamination

Teflon lamination is widely applied in industries requiring flexible, chemical-resistant films, such as electrical insulation, food packaging, and protective garment manufacture. Its ability to provide non-stick, moisture-resistant surfaces makes it ideal for sealing and barrier applications in pharmaceuticals and electronics. This lamination method enhances durability and performance without altering the underlying material's mechanical properties.

Cost Analysis: Teflon Coating vs Lamination

Teflon coating generally incurs lower upfront costs compared to Teflon lamination due to simpler application processes and reduced material usage. Lamination, while more expensive initially, offers superior durability and longer lifespan, potentially lowering long-term replacement expenses. Cost analysis should weigh immediate budget constraints against projected maintenance and performance benefits for optimal investment decisions.

Choosing the Right Solution: Factors to Consider

Teflon coating offers superior non-stick properties and chemical resistance, ideal for cookware and industrial applications requiring durability and ease of cleaning. Teflon lamination provides enhanced surface protection and flexibility, often used in textiles and packaging where a thin, protective layer is essential. When choosing between Teflon coating and lamination, consider factors such as intended use, exposure to heat and chemicals, required durability, and the substrate material compatibility.

Teflon Coating vs Teflon Lamination Infographic

materialdif.com

materialdif.com