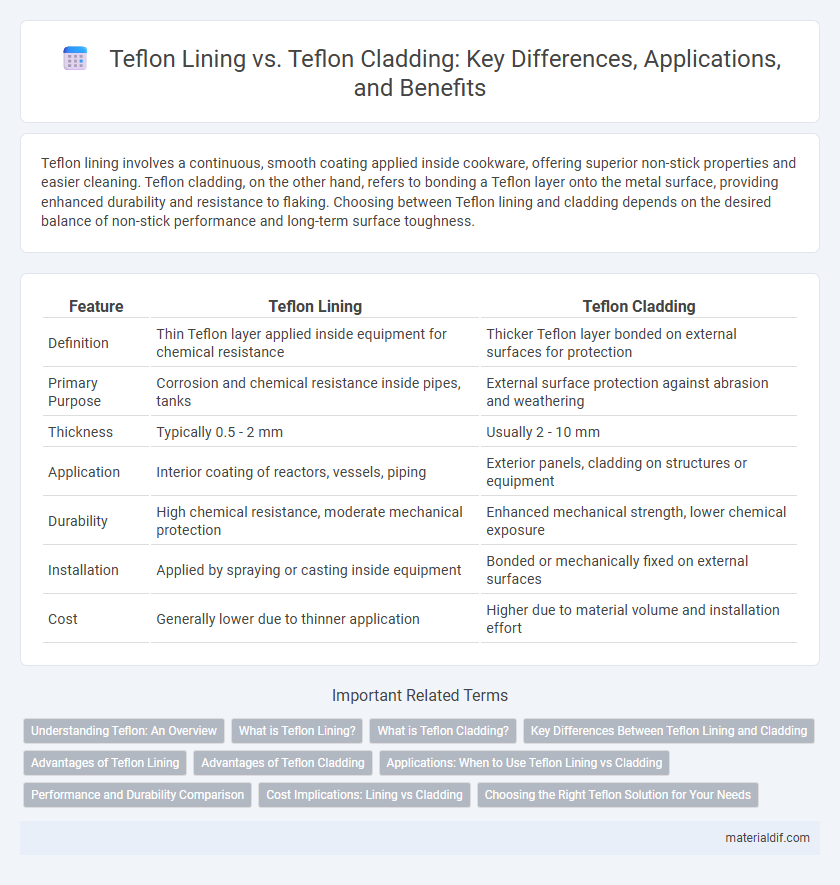

Teflon lining involves a continuous, smooth coating applied inside cookware, offering superior non-stick properties and easier cleaning. Teflon cladding, on the other hand, refers to bonding a Teflon layer onto the metal surface, providing enhanced durability and resistance to flaking. Choosing between Teflon lining and cladding depends on the desired balance of non-stick performance and long-term surface toughness.

Table of Comparison

| Feature | Teflon Lining | Teflon Cladding |

|---|---|---|

| Definition | Thin Teflon layer applied inside equipment for chemical resistance | Thicker Teflon layer bonded on external surfaces for protection |

| Primary Purpose | Corrosion and chemical resistance inside pipes, tanks | External surface protection against abrasion and weathering |

| Thickness | Typically 0.5 - 2 mm | Usually 2 - 10 mm |

| Application | Interior coating of reactors, vessels, piping | Exterior panels, cladding on structures or equipment |

| Durability | High chemical resistance, moderate mechanical protection | Enhanced mechanical strength, lower chemical exposure |

| Installation | Applied by spraying or casting inside equipment | Bonded or mechanically fixed on external surfaces |

| Cost | Generally lower due to thinner application | Higher due to material volume and installation effort |

Understanding Teflon: An Overview

Teflon lining involves coating the interior surfaces of containers or pipes with a thin layer of polytetrafluoroethylene (PTFE) to provide chemical resistance and non-stick properties, essential in industries such as chemical processing and food manufacturing. Teflon cladding, on the other hand, refers to bonding a thicker PTFE layer onto metal surfaces, offering enhanced durability and corrosion protection in harsh environments. Understanding the distinction between Teflon lining and cladding is crucial for selecting the appropriate application based on factors like chemical exposure, mechanical stress, and operational temperature ranges.

What is Teflon Lining?

Teflon lining refers to the process of applying a thin, durable layer of polytetrafluoroethylene (PTFE) inside equipment, such as pipes, tanks, or vessels, to protect against corrosion, chemical reactions, and abrasion. This non-stick coating enhances cleanliness and reduces material buildup, making it ideal for industries like chemical processing, pharmaceuticals, and food production. Unlike Teflon cladding, which involves layering PTFE onto an outer surface, Teflon lining is specifically designed to shield interior surfaces from harsh substances and extend the lifespan of equipment.

What is Teflon Cladding?

Teflon cladding refers to a process where a thin layer of Teflon (PTFE) is fused onto the surface of metal or other materials to enhance corrosion resistance, reduce friction, and provide non-stick properties. Unlike Teflon lining, which involves applying a bulk coating inside containers or pipes, cladding forms a durable, integral protective barrier on external surfaces. This technique is widely used in industrial applications requiring chemical resistance and longevity, such as in heat exchangers, pipes, and cookware exteriors.

Key Differences Between Teflon Lining and Cladding

Teflon lining involves applying a thin, non-stick polymer coating to the interior surfaces of containers or pipes, providing chemical resistance and preventing material adhesion. Teflon cladding refers to bonding a thicker layer of Teflon onto the exterior or surface of metal substrates, offering enhanced durability and corrosion protection. The key differences lie in lining's focus on internal anti-corrosive properties and ease of cleaning versus cladding's role in mechanical reinforcement and surface wear resistance.

Advantages of Teflon Lining

Teflon lining provides superior chemical resistance and non-stick properties, making it ideal for protecting tanks and pipes from corrosive substances. It offers excellent temperature tolerance, ensuring durability in extreme industrial environments while maintaining a smooth surface that prevents material buildup. Compared to cladding, Teflon lining allows seamless application inside vessels, enhancing contamination resistance and simplifying cleaning processes.

Advantages of Teflon Cladding

Teflon cladding provides superior chemical resistance and durability compared to Teflon lining, making it ideal for harsh industrial applications involving corrosive substances. Its seamless application reduces the risk of peeling or flaking, ensuring extended equipment lifespan and minimal maintenance. Cladding also offers improved mechanical strength and temperature resistance, enhancing performance in high-stress environments.

Applications: When to Use Teflon Lining vs Cladding

Teflon lining is ideal for applications requiring chemical resistance and corrosion protection in tanks, pipes, and reactors handling aggressive chemicals or high-purity substances. Teflon cladding is preferred for industries needing surface durability with a chemically inert layer on metal substrates, such as heat exchangers, flanges, and industrial panels exposed to abrasive or corrosive environments. Choosing between lining and cladding depends on factors like temperature tolerance, mechanical stress, and ease of inspection or maintenance in process equipment.

Performance and Durability Comparison

Teflon lining provides a smooth, non-stick surface that excels in chemical resistance and ease of cleaning, making it ideal for cookware and industrial containers. Teflon cladding, while offering similar resistance, typically adds a tougher outer layer that enhances mechanical durability and scratch resistance under high-stress conditions. In terms of longevity, Teflon cladding often outperforms lining by maintaining structural integrity amid physical wear, whereas lining is more vulnerable to abrasion but superior in seamless chemical protection.

Cost Implications: Lining vs Cladding

Teflon lining typically involves applying a smooth, non-reactive PTFE coating inside pipes or equipment, leading to lower initial costs but potential higher maintenance over time due to wear and possible reapplication. Teflon cladding, which bonds a thicker PTFE layer to metal surfaces, generally incurs higher upfront expenses but offers enhanced durability and extended service life, reducing long-term replacement and repair costs. Cost implications between Teflon lining and cladding depend on factors such as application environment, longevity requirements, and maintenance capabilities, influencing overall operational expenditure.

Choosing the Right Teflon Solution for Your Needs

Choosing the right Teflon solution depends on the application's requirements for chemical resistance, temperature tolerance, and mechanical durability. Teflon lining offers superior chemical protection and is ideal for pipes and tanks exposed to corrosive substances, while Teflon cladding provides a robust surface coating for metals, enhancing wear resistance without modifying the substrate's mechanical properties. Evaluating factors like exposure conditions, installation process, and cost-effectiveness ensures optimal performance and longevity in your specific environment.

Teflon Lining vs Teflon Cladding Infographic

materialdif.com

materialdif.com