Etched PTFE offers superior adhesion compared to standard PTFE due to its enhanced surface texture created through chemical or plasma etching processes. This modification improves bonding strength with coatings, adhesives, and other materials, making it ideal for applications requiring durable and reliable surface interactions. Standard PTFE, while excellent for chemical resistance and low friction, lacks this enhanced adhesion capability, limiting its use in certain industrial and manufacturing contexts.

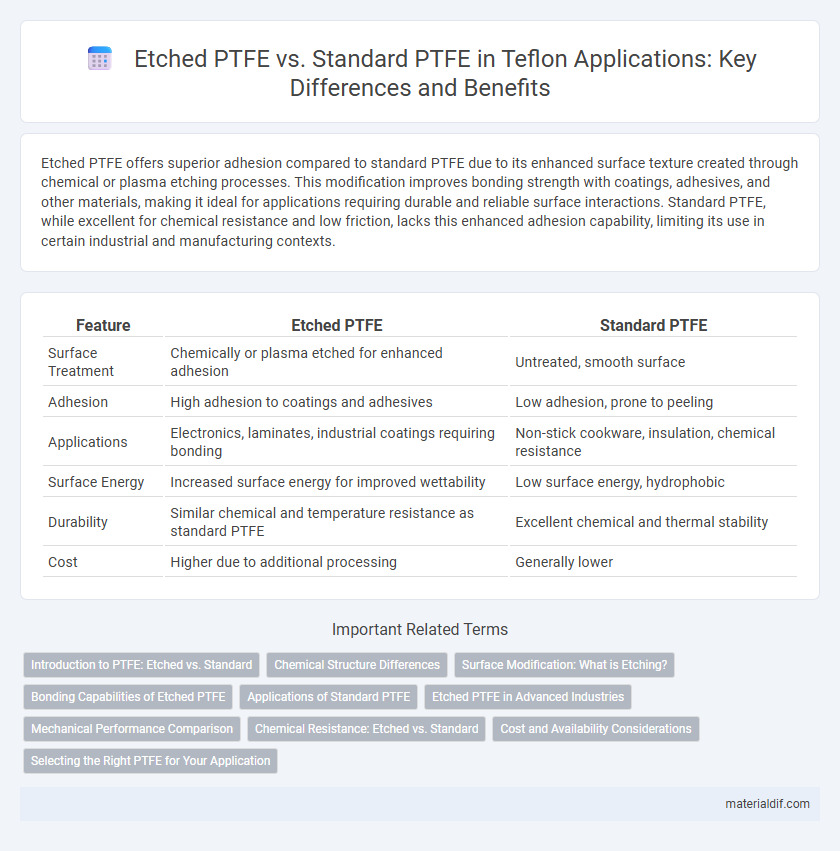

Table of Comparison

| Feature | Etched PTFE | Standard PTFE |

|---|---|---|

| Surface Treatment | Chemically or plasma etched for enhanced adhesion | Untreated, smooth surface |

| Adhesion | High adhesion to coatings and adhesives | Low adhesion, prone to peeling |

| Applications | Electronics, laminates, industrial coatings requiring bonding | Non-stick cookware, insulation, chemical resistance |

| Surface Energy | Increased surface energy for improved wettability | Low surface energy, hydrophobic |

| Durability | Similar chemical and temperature resistance as standard PTFE | Excellent chemical and thermal stability |

| Cost | Higher due to additional processing | Generally lower |

Introduction to PTFE: Etched vs. Standard

Etched PTFE undergoes a surface modification process that increases its adhesion properties compared to standard PTFE, which has a smooth, non-stick surface. This enhanced bonding ability makes etched PTFE ideal for applications requiring strong coating or printing adhesion, such as in electronics and automotive components. Standard PTFE retains excellent chemical resistance and low friction but lacks the surface energy needed for effective adhesion without additional treatments.

Chemical Structure Differences

Etched PTFE exhibits a modified chemical structure compared to standard PTFE, featuring increased surface energy and enhanced reactivity due to the introduction of polar functional groups during the etching process. This alteration results in improved adhesion properties without significantly changing the overall fluorocarbon backbone, maintaining PTFE's characteristic chemical resistance. Standard PTFE, characterized by its fully fluorinated carbon chain with strong carbon-fluorine bonds, remains highly inert and hydrophobic, limiting surface modifications and adhesive bonding.

Surface Modification: What is Etching?

Etching is a surface modification process applied to PTFE (Polytetrafluoroethylene) to enhance its adhesion properties by creating micro-roughness through chemical or plasma treatment. Etched PTFE exhibits improved surface energy compared to standard PTFE, which naturally has a low surface energy resulting in poor adhesion. This modification facilitates better bonding with coatings, adhesives, and inks, expanding its application potential in industries requiring strong adhesion.

Bonding Capabilities of Etched PTFE

Etched PTFE significantly improves bonding capabilities compared to standard PTFE by increasing surface energy and roughness through chemical or plasma etching processes. This enhanced surface allows adhesives, coatings, and paints to adhere more effectively, reducing delamination risks in applications requiring strong, durable bonds. Etched PTFE is essential in industries such as electronics and aerospace, where reliable bonding to PTFE surfaces is critical.

Applications of Standard PTFE

Standard PTFE is widely utilized in industries requiring excellent chemical resistance and low friction, such as in gaskets, seals, and non-stick cookware coatings. Its exceptional electrical insulation properties make it ideal for use in wiring and cable insulation in aerospace and electronics. Standard PTFE's high thermal stability also suits it for use in heat exchangers and laboratory equipment, where durable, non-reactive materials are essential.

Etched PTFE in Advanced Industries

Etched PTFE offers superior adhesion properties compared to standard PTFE, making it essential in advanced industries such as aerospace, electronics, and medical device manufacturing. The micro-etching process enhances surface energy, enabling stronger bonding with coatings, adhesives, and inks, which is critical for high-performance applications requiring durability and chemical resistance. Its ability to maintain PTFE's inherent non-stick and corrosion-resistant qualities while improving mechanical integration drives its preference in cutting-edge industrial uses.

Mechanical Performance Comparison

Etched PTFE exhibits significantly improved mechanical performance compared to standard PTFE due to its enhanced surface roughness, which increases adhesion properties and tensile strength. Mechanical testing reveals that etched PTFE can withstand higher shear forces and exhibits greater resistance to delamination under stress. These improvements make etched PTFE preferable for applications requiring durable bonding and enhanced structural integrity.

Chemical Resistance: Etched vs. Standard

Etched PTFE exhibits enhanced surface roughness compared to standard PTFE, improving adhesion without significantly affecting its inherent chemical resistance. Both etched and standard PTFE maintain exceptional resistance to chemicals, including strong acids, bases, and solvents, due to their highly inert molecular structure. The etching process primarily modifies surface properties for bonding purposes, leaving the chemical resistance characteristics largely unchanged.

Cost and Availability Considerations

Etched PTFE typically incurs higher costs compared to standard PTFE due to additional surface treatment processes that improve adhesion properties. Availability of etched PTFE may be limited, as it requires specialized manufacturing facilities, whereas standard PTFE is widely produced and readily accessible in various forms globally. Budget constraints and project timelines often influence the choice between etched and standard PTFE based on cost-efficiency and supply chain reliability.

Selecting the Right PTFE for Your Application

Etched PTFE offers enhanced surface adhesion compared to standard PTFE, making it ideal for applications requiring strong bonding with adhesives, coatings, or other materials. Selecting etched PTFE ensures better durability and stability in high-performance industries such as aerospace, electronics, and medical devices. Standard PTFE is suitable for applications prioritizing chemical resistance and low friction without the need for bonding enhancements.

etched PTFE vs standard PTFE Infographic

materialdif.com

materialdif.com